Preparation method of Ti4O7 coating on surface of metal titanium bipolar plate of proton exchange membrane fuel cell

A proton exchange membrane, fuel cell technology, applied in fuel cells, metal material coating process, coating and other directions, can solve the problem of forming conditions restricting the development of coating, achieve uniform and dense coating, experimental process safety, guarantee The effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

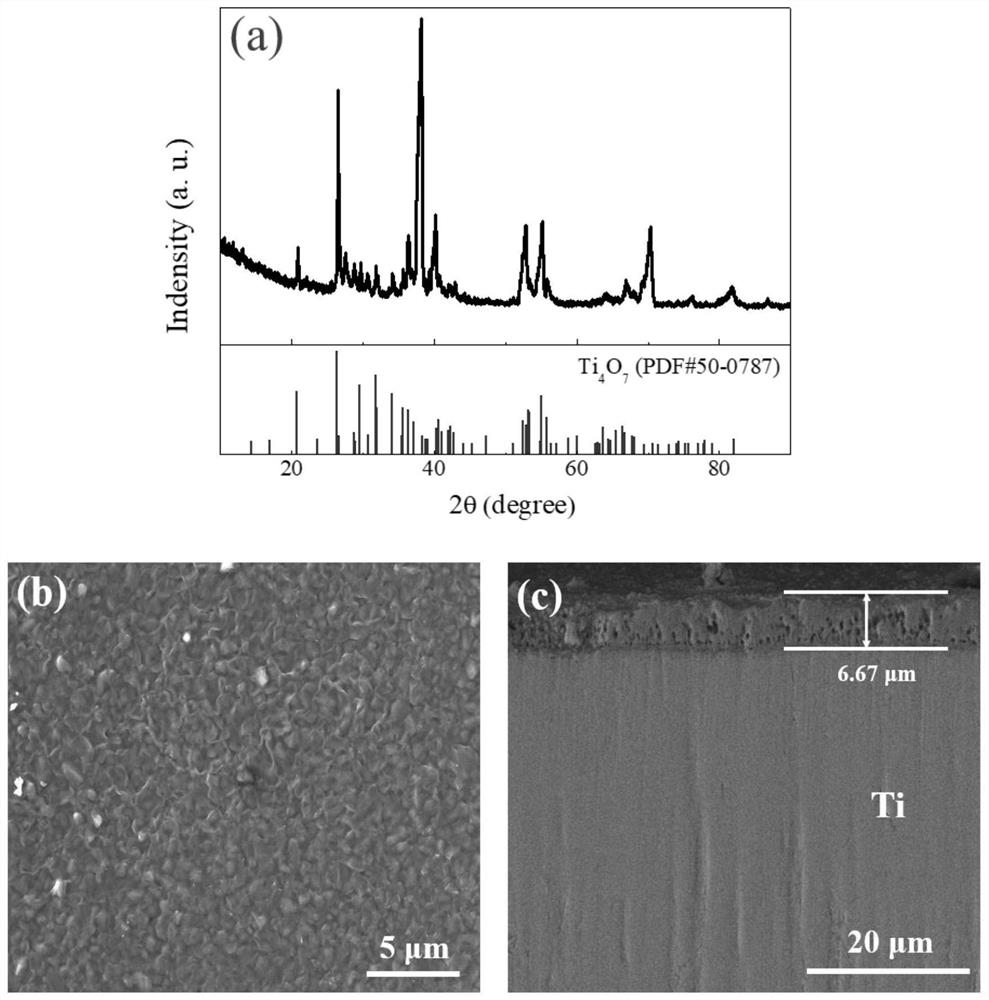

Embodiment 1

[0028] Example 1, Ti 4 o 7 The preparation method of the coating is as follows:

[0029] (1) Substrate pretreatment: use pure Ti plate as the base material, cut the Ti plate base material into thin slices of length × width × height = 10mm × 10mm × 2mm, and pretreat the base material, that is, use 600-mesh and 1000-mesh sandpaper Polish the Ti plate base material in turn, and then place it in acetone solution and pure water for ultrasonic treatment in turn. During the treatment, put it in an ultrasonic cleaner for 3 to 5 minutes to remove oil. The temperature of ultrasonic cleaning is room temperature, and then Then put it into an oven at 200° C. for 10 minutes to dry.

[0030] (2) Preparation of TiO 2 Thin film: Put the Ti plate substrate treated in step (1) into a tube furnace and calcine and oxidize it in the air at 700°C for 420min to obtain a layer of rutile TiO on the surface of the Ti plate substrate. 2 Thin film; during calcination, the temperature was raised to 700...

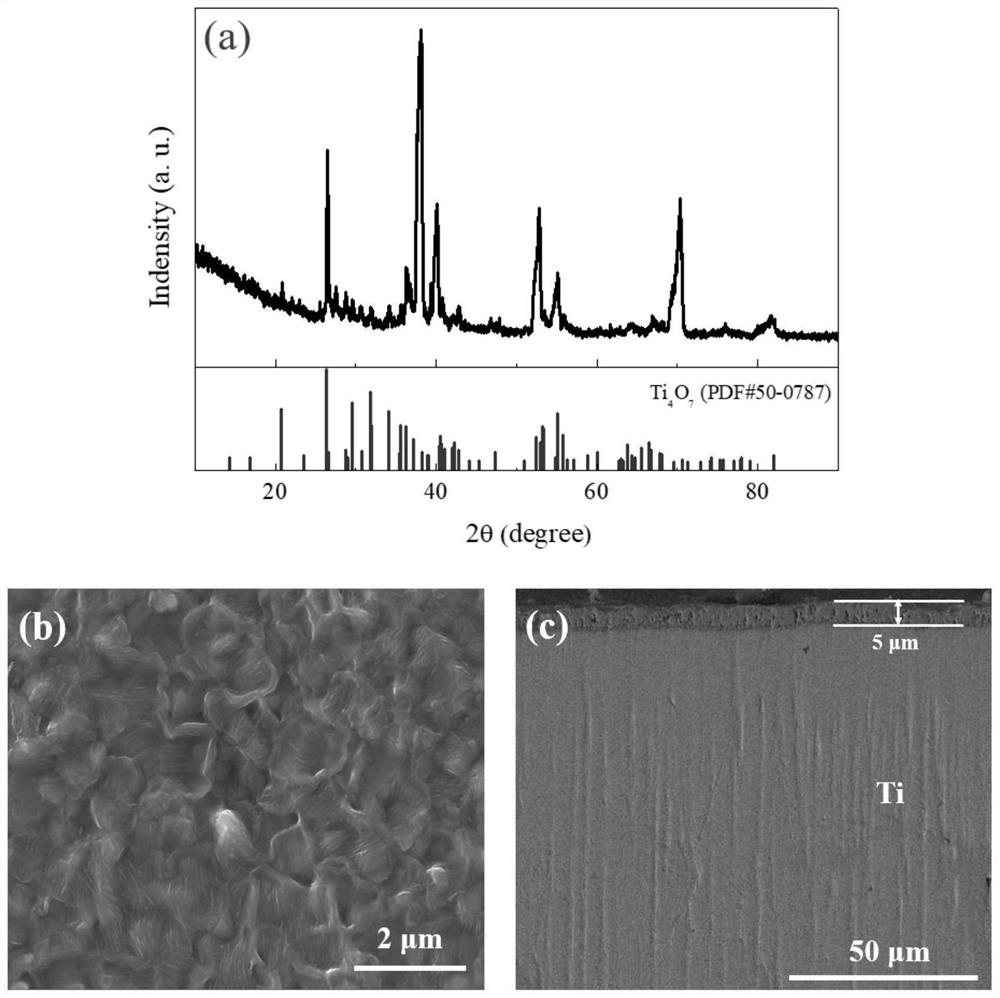

Embodiment 2

[0034] Example 2, Al 2 o 3 The preparation method of composite coating is as follows:

[0035] (1) Substrate pretreatment: use pure Ti plate as the base material, cut the Ti plate base material into thin slices of length × width × height = 10mm × 10mm × 2mm, and pretreat the base material, that is, use 600-mesh and 1000-mesh sandpaper Grind the base material of the Ti plate respectively, and then place it in acetone solution and pure water for ultrasonic treatment in turn. During the treatment, place it in an ultrasonic cleaner for 3 to 5 minutes to remove oil. The temperature of the ultrasonic cleaning is room temperature, and then Then put it into an oven at 200° C. for 10 minutes to dry.

[0036] (2) Preparation of TiO 2 Thin film: Put the Ti plate base material treated in step (1) into a tube furnace and calcine and oxidize it in the air at 700°C for 420min. A layer of rutile TiO is obtained on the surface of the board substrate 2 film.

[0037] (3) Preparation of mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com