Waste recycling environment-friendly metallurgical furnace control method and system

A technology of waste recycling and control method, which is applied in the field of control methods and control systems for environmental protection metallurgical furnaces of waste recycling, can solve the problems of affecting production safety, inaccurate control, and many manual participation parts, etc., so as to improve production safety and ensure operation. environment, the possible effect of reducing the possibility of misinterpretation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

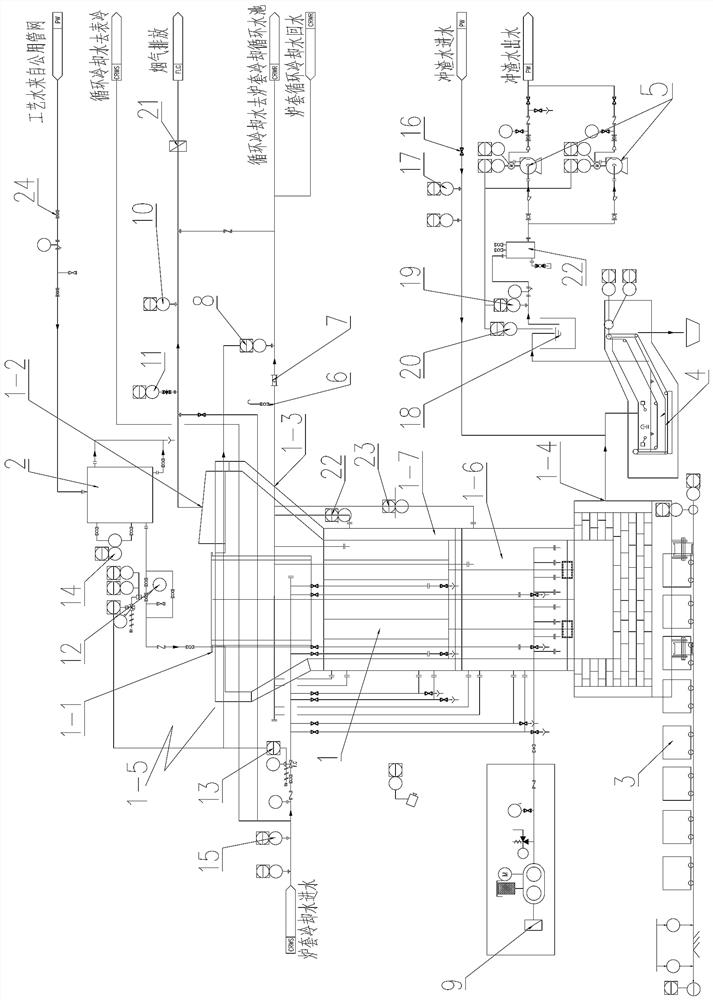

[0065] Such as figure 1 As shown, the present invention is a waste recycling environment-friendly metallurgical furnace system, which includes: a smelting furnace body 1, a slag extractor 4, an emergency water tank 2, a supplementary fan 9, and an induced draft fan 20; the smelting furnace body 1 includes a smelting furnace cover 1-5, cooling water inlet 1-1 and cooling water outlet 1-3 are set on the smelting furnace jacket 1-5, and the smelting furnace jacket 1-5 includes the upper water jacket 1-7 and the lower water jacket respectively provided with water outlet pipelines 1-6; the top of the smelting furnace body 1 is provided with a smoke outlet 1-2, and the bottom is provided with a slag outlet 1-4; the smoke outlet 1-2 is connected to the flue gas treatment system through the flue gas channel (not marked in the figure); cooling water The inlet 1-1 is connected to the external cooling water supply pool (not marked in the figure) through the cooling water inlet pipeline, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com