Microwave module integration design method, and microwave module produced by using method

A technology of microwave components and design methods, which is applied in the direction of waveguide devices, electrical components, circuits, etc., can solve the problems of high difficulty in assembly, high proportion of structural parts, and increased cost of circuit boards, so as to reduce the use of metal materials and reduce The difficulty of process assembly and the effect of reducing cost expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

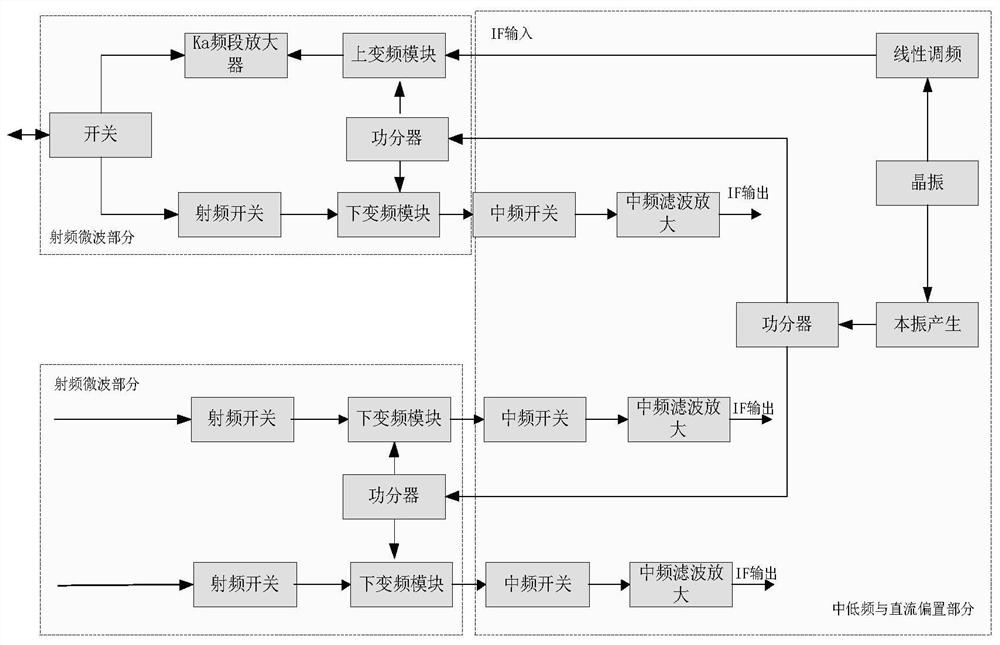

[0035] Such as figure 1 As shown, an integrated design method for microwave components, the unit circuit of the microwave component mainly includes a radio frequency microwave part, a medium and low frequency part, and a DC bias part from the perspective of the working frequency band;

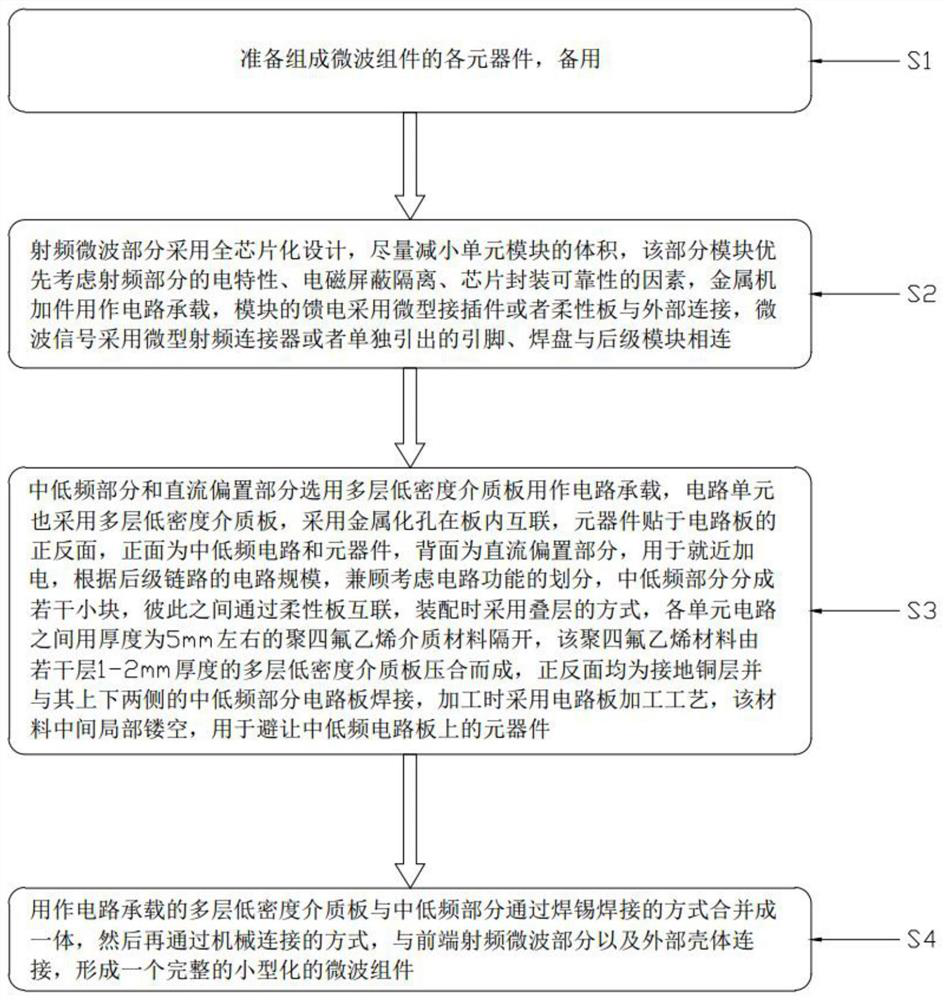

[0036] The integrated design method of the above-mentioned microwave components includes the following steps:

[0037] S1. Prepare the various components that make up the microwave assembly and set them aside;

[0038] S2. The radio frequency and microwave part adopts a full-chip design to minimize the volume of the unit module. This part of the module gives priority to the electrical characteristics of the radio frequency part, electromagnetic shielding and isola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com