Renewable PVDF membrane with adsorption function and preparation method thereof

A technology of function and preparation steps, applied in the field of renewable PVDF membrane with adsorption function and its preparation, can solve the problems of difficult control of grafting effect, high free radical activity, complicated technical process, etc., and achieve both adsorption effect and reproducibility Renewable, easy to recycle, simple effect of renewable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

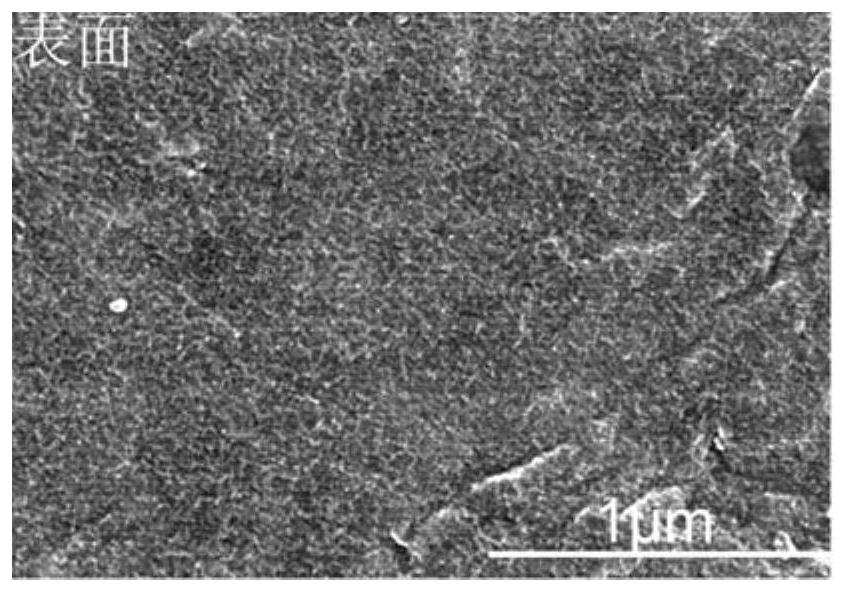

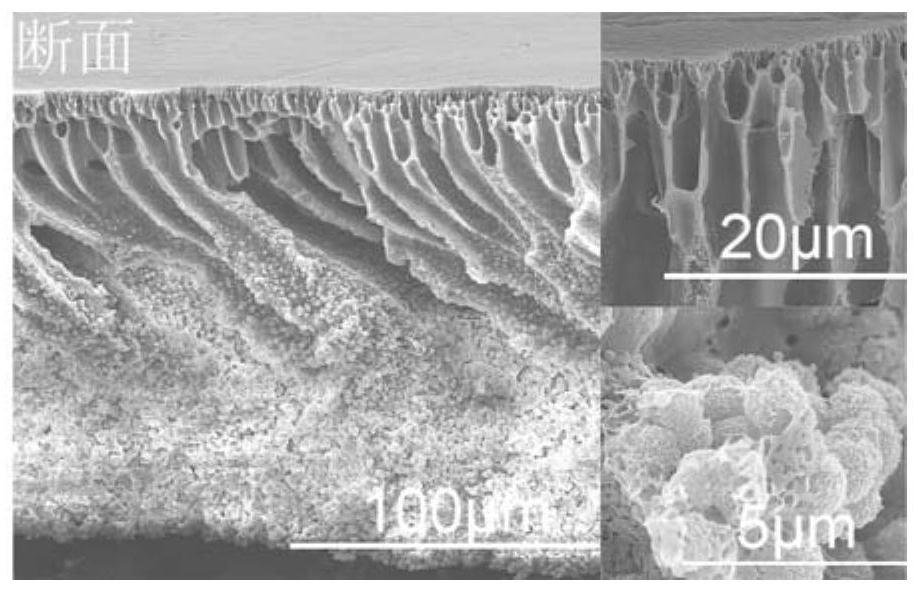

[0060] A kind of preparation method of renewable PVDF membrane I with adsorption function, concrete preparation steps are as follows:

[0061] S1. Introduce hydroxyl groups in the process of preparing PVDF membranes to form active PVDF membranes:

[0062] S101. Preparation of casting solution: 20 parts by weight of polyvinylidene fluoride, 6 parts by weight of polyethylene glycol-600 and 74 parts by weight of dimethyl sulfoxide were mixed and stirred evenly, and heated and stirred in a water bath at 70° C. for 4 hours, and then Static defoaming for 4 hours, cooled to room temperature for use;

[0063] S102, preparing a coagulation bath: dissolving polyvinyl alcohol with a molecular weight of 24200 in distilled water at 70°C to prepare a 10wt.% polyvinyl alcohol solution;

[0064] S103. Film preparation: Pour the casting solution on a glass plate and scrape it into a liquid film with a thickness of 500 μm, put it in a coagulation bath with a constant temperature of 25°C, and s...

Embodiment 2

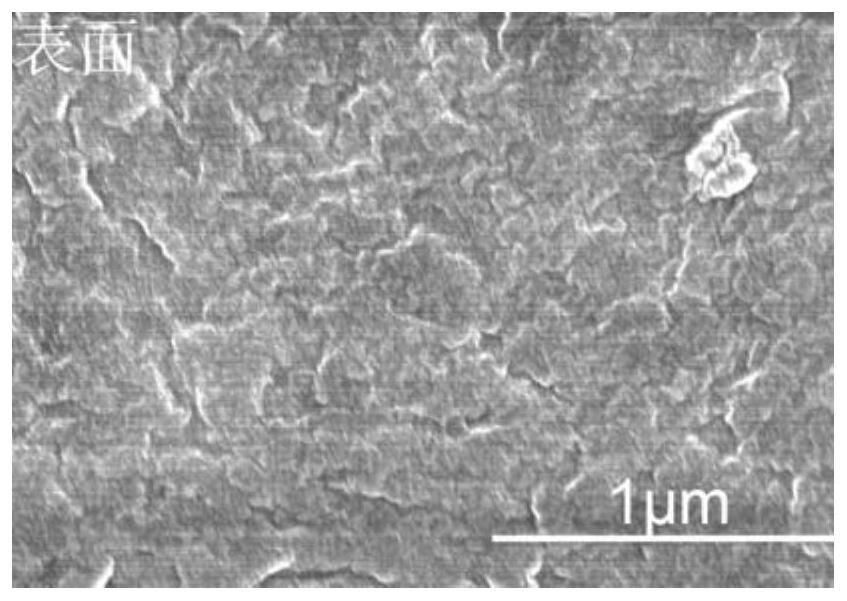

[0080] A method for preparing a renewable PVDF membrane II with adsorption function, the specific preparation steps are as follows:

[0081] S1. Introduce hydroxyl groups in the process of preparing PVDF membranes to form active PVDF membranes:

[0082] S101. Preparation of casting solution: 20 parts by weight of polyvinylidene fluoride, 6 parts by weight of polyethylene glycol-600 and 74 parts by weight of dimethyl sulfoxide were mixed and stirred evenly, and heated and stirred in a water bath at 70° C. for 4 hours, and then Static defoaming for 4 hours, cooled to room temperature for use;

[0083] S102, preparing a coagulation bath: dissolving polyvinyl alcohol with a molecular weight of 24200 in distilled water at 70°C to prepare a 5wt.% polyvinyl alcohol solution;

[0084] S103. Film preparation: Pour the casting solution on a glass plate and scrape it into a liquid film with a thickness of 500 μm, put it in a coagulation bath with a constant temperature of 25°C, and soli...

Embodiment 3

[0095] A method for preparing a renewable PVDF membrane III with adsorption function, the specific preparation steps are as follows:

[0096] S1. Introduce hydroxyl groups in the process of preparing PVDF membranes to form active PVDF membranes:

[0097] S101. Preparation of casting solution: 20 parts by weight of polyvinylidene fluoride, 6 parts by weight of polyethylene glycol-600 and 74 parts by weight of dimethyl sulfoxide were mixed and stirred evenly, and heated and stirred in a water bath at 70° C. for 4 hours, and then Static defoaming for 4 hours, cooled to room temperature for use;

[0098] S102, preparing a coagulation bath: dissolving polyvinyl alcohol with a molecular weight of 24200 in distilled water at 70°C to prepare a 5wt.% polyvinyl alcohol solution;

[0099] S103. Film preparation: Pour the casting solution on a glass plate and scrape it into a liquid film with a thickness of 500 μm, put it in a coagulation bath with a constant temperature of 25°C, and sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com