Preparation method of tall oil acid-based imidazoline biquaternary ammonium salt surfactant

A technology of oleic acid alkylimidazoline and surfactant, which is applied in the direction of sulfonate preparation, chemical instruments and methods, organic chemistry, etc., can solve problems such as unfavorable industrialization and surfactant product residue, and improve alkali resistance And electrolyte resistance, enhanced hydrophilicity, good effect of alkali and acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

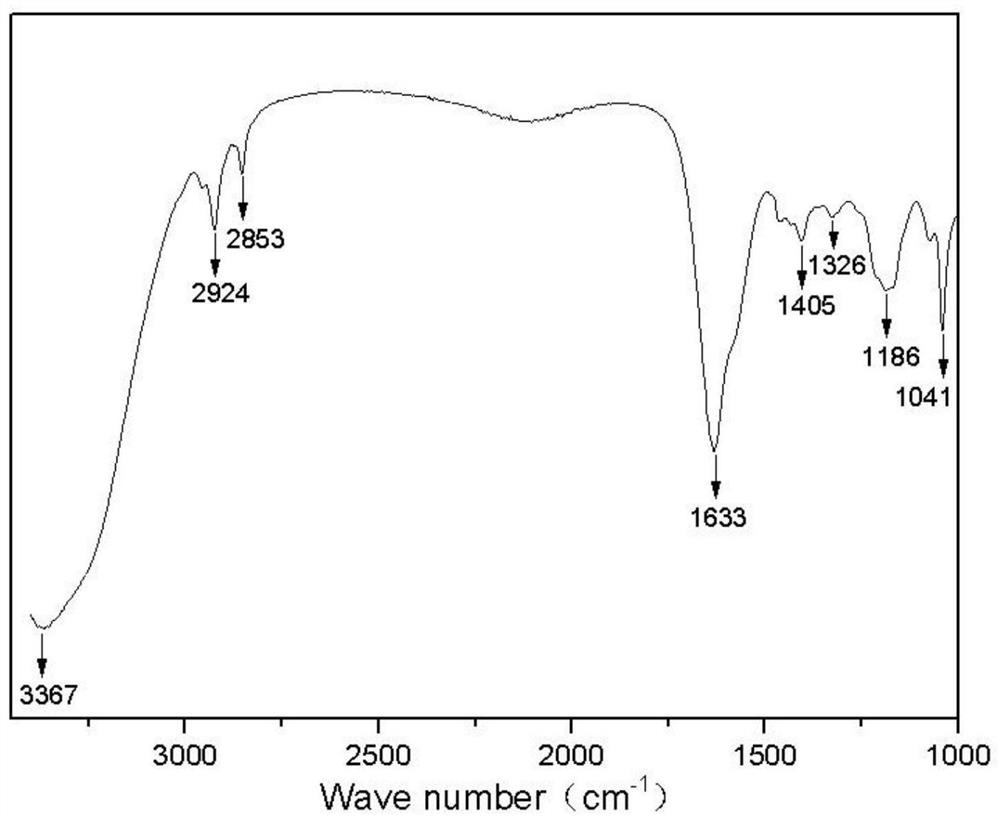

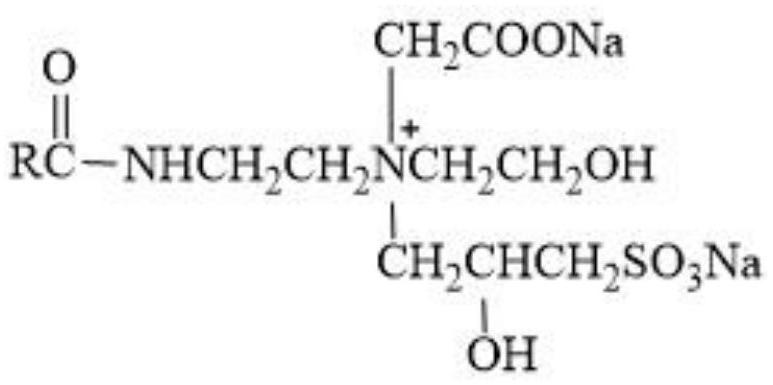

[0044] The synthetic route of the present invention is as follows:

[0045]

[0046] Among them, R is mainly oleic acid alkyl group, linoleic acid alkyl group, a small amount of rosin acid alkyl group and a small amount of saturated fatty acid alkyl group.

[0047] Alkyl group of oleic acid: CH 3 (CH 2 ) 7 CH=CH(CH 2 ) 7 -

[0048] Alkyl group of linoleic acid: CH 3 (CH 2 ) 4 CH=CHCH 2 CH=CH(CH 2 ) 7 -

[0049] Alkyl group of rosin acid:

[0050] Saturated fatty acid alkyl group: CH 3 (CH 2 ) 14 -CH 3 (CH 2 ) 16 -.

[0051] In a 500mL four-necked flask equipped with an electric stirrer, a thermometer, and a condenser tube, add a tall oleic acid alkylimidazoline intermediate (0.15 moles, 53.1 grams), 176.2 grams of deionized water, raise the temperature to 70°C, and then add Sodium 3-chloro-2-hydroxypropanesulfonate (0.15 moles, 29.5 grams), reacted for 4 hours, then added chloroacetic acid (0.15 moles, 14.2 grams) and potassium hydroxide (0.45 moles,...

Embodiment 2

[0054] In a 500mL four-necked flask equipped with an electric stirrer, a thermometer, and a condenser tube, add a tall oleic acid alkylimidazoline intermediate (0.15 moles, 53.1 grams), 161.7 grams of deionized water, heat up to 80°C, and then add Sodium 3-chloro-2-hydroxypropanesulfonate (0.12 moles, 23.6 grams), reacted for 2.5 hours, then added chloroacetic acid (0.18 moles, 17.0 grams) and sodium hydroxide (0.465 moles, 18.6 grams) at the same time, after reacting for 3 hours A light yellow transparent liquid was obtained, and a tall oleic acid alkyl imidazoline diquaternary ammonium surfactant was obtained. The conversion rate of the tall oleic acid alkyl imidazoline intermediate was measured to be 97.7%, and the solid content was 45%.

Embodiment 3

[0056] In a 500mL four-necked flask equipped with an electric stirrer, a thermometer, and a condenser tube, add the tall oleic acid alkyl imidazoline intermediate (0.15 mol, 53.1 g) and 184.6 g of deionized water, raise the temperature to 75°C, and then add Sodium 3-chloro-2-hydroxypropanesulfonate (0.18 moles, 32.4 grams), reacted for 3.0h, then added chloroacetic acid (0.165 moles, 15.57 grams) and potassium hydroxide (0.48 moles, 26.9 grams) at the same time, reacted for 4.5h Afterwards, a light yellow transparent liquid was obtained, and a tall oleic acid alkyl imidazoline diquaternary ammonium surfactant was obtained. The conversion rate of the tall oleic acid alkyl imidazoline intermediate was measured to be 96.5%, and the solid content was 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com