Machining process of full-band radar camouflage net

A processing technology and technology of camouflage nets, which are applied in the field of camouflage nets to achieve the effects of light weight, convenient manual carrying and easy control of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

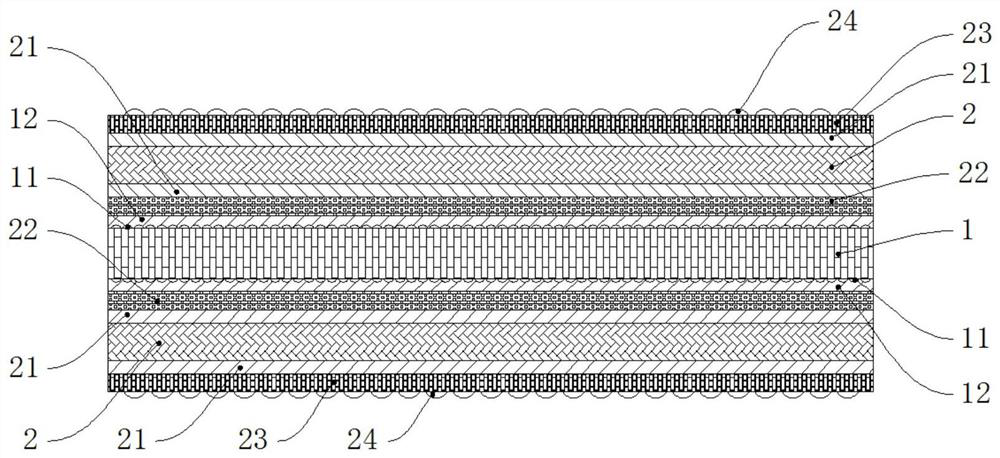

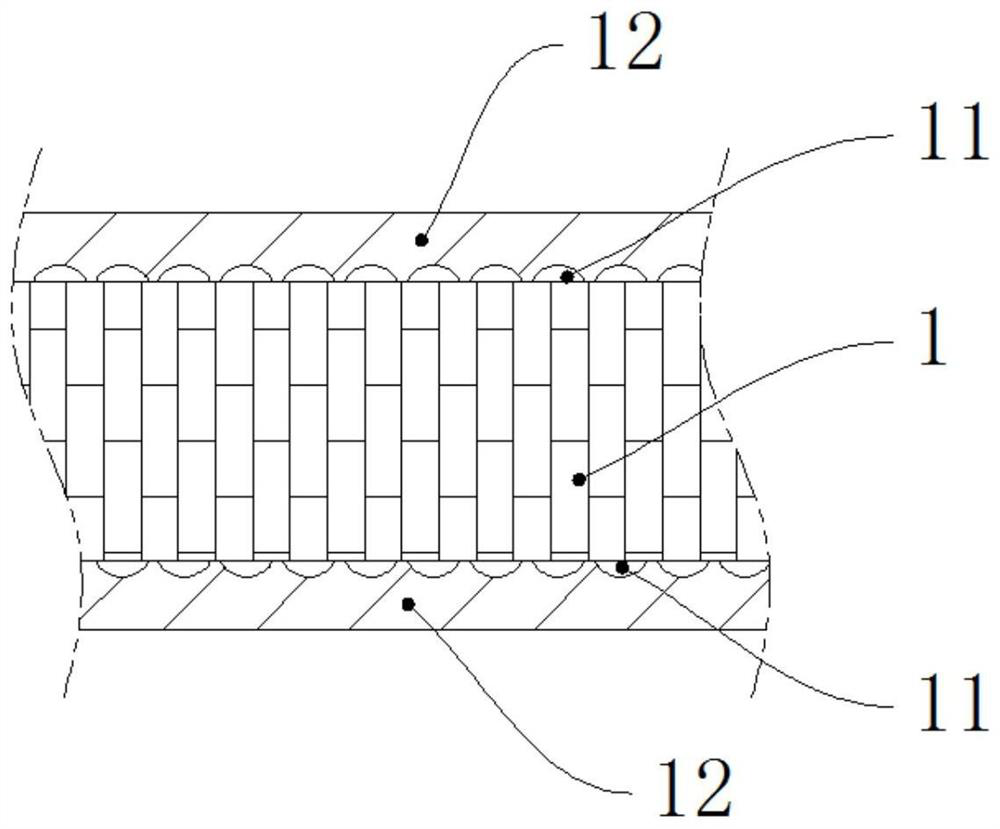

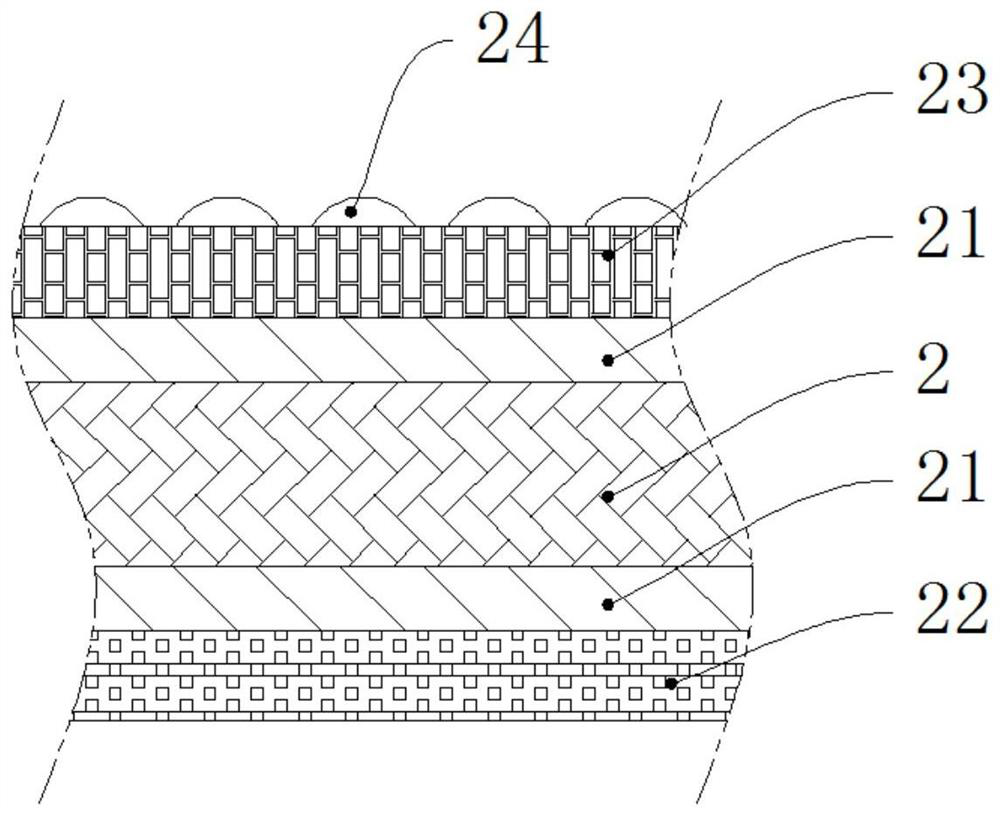

[0035] A kind of processing technology of all-band radar camouflage net:

[0036] First make the camouflage mesh foam base layer 1, get 70 mass parts of polyolefin, 6 mass parts of modified carbon nanotubes, 3 mass parts of modified graphene, 3 mass parts of rare earth, 6 mass parts of melamine flame retardant agent, 8 parts by mass of nitroso blowing agent, 10 parts by mass of dialkoxyacetophenone sensitizer and 3 parts by mass of dibutyl hydroxytoluene antioxidant.

[0037] Add the above ingredients into a mixer and mix them evenly. Before mixing, the polyolefin needs to be ground into powder, and the particle size is 7500 mesh. Before mixing the modified carbon nanotubes and modified graphene, add 0.5% titanate coupling agent, 0.2% cationic quaternary ammonium salt antistatic agent for dispersion modification.

[0038] Then the mixture is sent to a tablet extruder to be extruded into a sheet, and the above sheet is irradiated at room temperature, and then subjected to high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com