Perovskite quantum dot material and preparation method and application thereof

A technology of quantum dot materials and perovskite, which is applied in nanotechnology, luminescent materials, chemical instruments and methods for materials and surface science, can solve problems such as fluorescence quenching, achieve high quenching pressure, and improve detection effect, the effect of short fluorescence lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

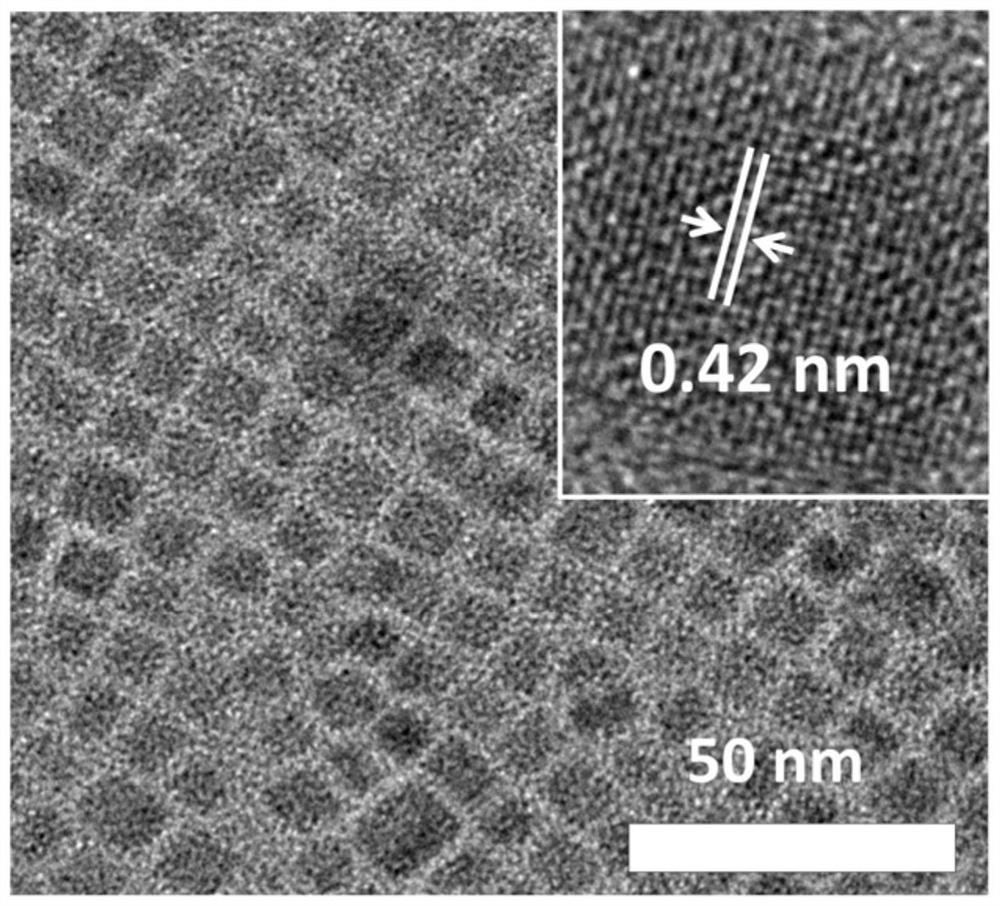

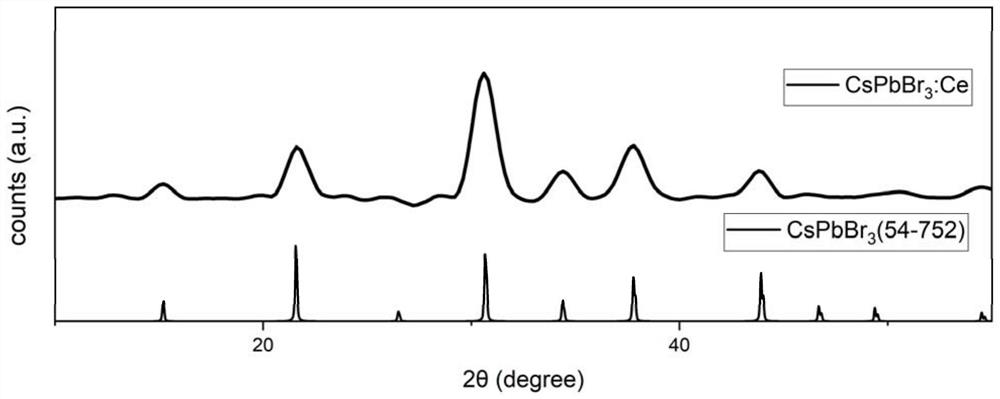

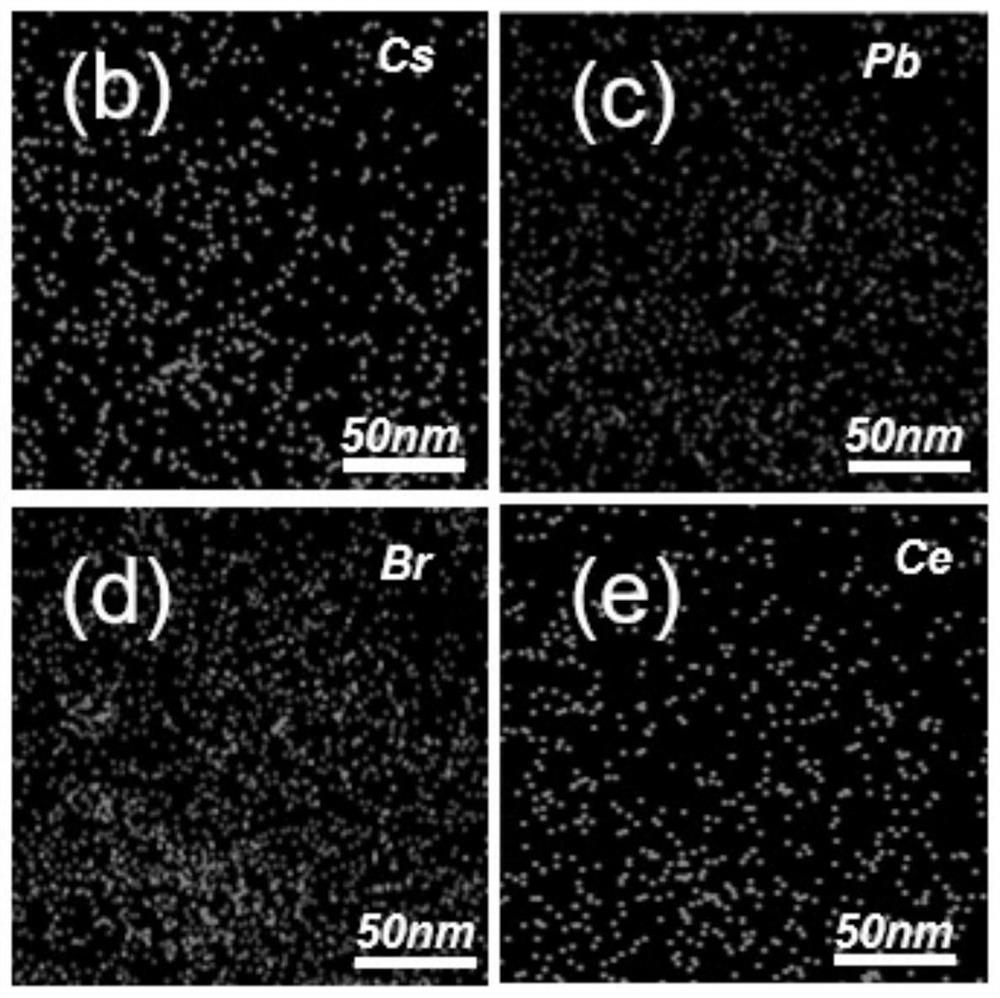

[0027] A kind of perovskite quantum dot material, its preparation method comprises the following steps:

[0028] (1) Mix 0.814g cesium carbonate, 40ml octadecene and 2.5ml oleic acid under vacuum conditions and heat up to 100°C for drying, then heat up to 140°C until cesium carbonate and oleic acid react completely to obtain cesium oleate solution;

[0029] (2) heating 0.069g of lead bromide and 5ml of octadecene to 100°C for drying under vacuum conditions to obtain a lead precursor solution;

[0030] (3) Warm up 0.018g of cerium bromide and 0.5ml of oleic acid to 50°C under vacuum until the cerium bromide is completely dissolved to obtain a cerium precursor solution;

[0031] (4) Under ambient conditions, inject 0.5ml of oleylamine and 0.5ml of the cerium precursor solution in step (3) into the lead precursor solution in step (2) respectively, and raise the temperature of the mixed solution to 170°C under vacuum , until lead bromide is completely dissolved;

[0032] (5) Un...

Embodiment 2

[0034] A kind of perovskite quantum dot material, its preparation method comprises the following steps:

[0035] (1) Mix 0.814g cesium carbonate, 40ml octadecene and 2.5ml oleic acid under vacuum conditions and heat up to 120°C for drying, then heat up to 150°C until cesium carbonate and oleic acid react completely to obtain cesium oleate solution;

[0036] (2) heating 0.069g of lead bromide and 5ml of octadecene to 120° C. for drying under vacuum conditions to obtain a lead precursor solution;

[0037] (3) Warm up 0.0214g cerium bromide and 0.5ml oleic acid to 60°C under vacuum until the cerium bromide is completely dissolved to obtain a cerium precursor solution;

[0038] (4) Under ambient conditions, inject 0.5ml of oleylamine and 0.5ml of the cerium precursor solution in step (3) into the lead precursor solution in step (2) respectively, and raise the temperature of the mixed solution to 180°C until bromine Lead chloride is completely dissolved;

[0039] (5) Under ambie...

Embodiment 3

[0041] A kind of perovskite quantum dot material, its preparation method comprises the following steps:

[0042] (1) Mix 0.814g cesium carbonate, 40ml octadecene and 2.5ml oleic acid under vacuum conditions and heat up to 120°C for drying, then heat up to 160°C until cesium carbonate and oleic acid react completely to obtain cesium oleate solution;

[0043] (2) heating 0.069g of lead bromide and 5ml of octadecene to 120° C. for drying under vacuum conditions to obtain a lead precursor solution;

[0044] (3) Warm up 0.025g of cerium bromide and 0.5ml of oleic acid to 70°C under vacuum until the cerium bromide is completely dissolved to obtain a cerium precursor solution;

[0045] (4) Under ambient conditions, inject 0.5ml of oleylamine and 0.5ml of the cerium precursor solution in step (3) into the lead precursor solution in step (2) respectively, and raise the temperature of the mixed solution to 190°C until bromine Lead chloride is completely dissolved;

[0046] (5) Under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com