Phosphatase mutant and application thereof in preparation of fructose by catalyzing maltodextrin

A maltodextrin and mutant technology, applied in the field of enzyme engineering, can solve the problems of increased cost of separation and purification, accumulation of by-products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Obtaining of Phosphatase Gene Sequence and Vector Construction

[0027] The polypeptide sequence (GenBank: WP_073073090.1) derived from T.atlanticus was obtained by mining NCBI and KEGG databases. The sequence has not been annotated, and its function is not yet clear. Under the premise of not changing the amino acid sequence of the polypeptide, the codons of the above genes are replaced with codons preferred by Escherichia coli (high frequency usage), and the nucleotide sequence of the phosphatase (M6PP) gene after codon optimization is shown as SEQ ID As shown in NO: 2, the amino acid sequence of the encoded protein is shown in SEQ ID NO: 1.

[0028] The gene sequence shown in SEQ ID NO: 2 was connected to the pET-28b(+) vector, located between the restriction sites BamHI and HindIII, and the recombinant plasmid was named pET-28b(+)-M6PP.

Embodiment 2

[0029] Example 2 Expression and purification of wild-type phosphatase M6PP

[0030] (1) Construction of recombinant bacteria: the recombinant plasmid pET-28b(+)-M6PP in Example 1 was transformed into E. coli BL21(DE3) competent cells to obtain wild-type recombinant bacteria.

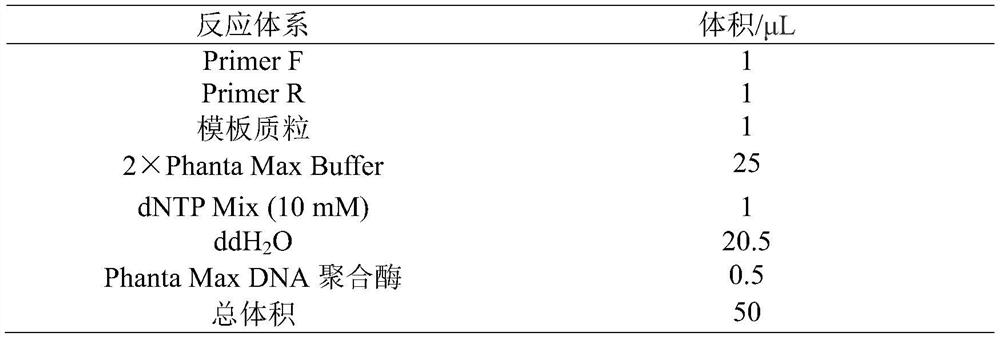

[0031] (2) Recombinant bacteria culture: pick the wild-type recombinant bacteria from step (1) into 10mL LB liquid medium, and cultivate to OD at 37°C and 200rpm 600 0.6-0.8; transfer 10mL culture medium to 100mL LB medium, add kanamycin to a final concentration of 50mg / L, and cultivate to OD at 37°C and 180rpm 600 When the temperature is 0.6-0.8, lower the temperature to 28°C, add IPTG to a final concentration of 0.1mM, and induce expression for 12h. The above culture solution was centrifuged at 8000×g for 10 min, the supernatant was discarded, and the pellet was resuspended with HEPES buffer (pH 7.2) to obtain the bacterial suspension.

[0032] (3) Preparation of crude enzyme solution: Step (2) Bacte...

Embodiment 3

[0033] The preparation of embodiment 3 α-GP, PGM, PGI enzyme solution

[0034] Using the method of Example 2, the glucan phosphorylase α-GP (GenBank: AHD18925.1, whose amino acid sequence is shown in SEQ ID NO: 11) derived from Thermotoga maritima MSB8, source Glucose phosphomutase PGM (GenBank: BAD42440.1, amino acid sequence shown in SEQ ID NO: 12) from Thermococcus kodakarensis KOD1, glucose from Thermococcus kodakarensis KOD1 (Thermusthermophilus HB8) Phosphate isomerase PGI (GenBank: BAD70100.1, the amino acid sequence is shown in SEQ ID NO: 13), connected to the pET-28b (+) carrier, the connection sites are both BamHI and HindIII, to obtain the corresponding expression vector, and then Transformed into E.coli BL21(DE3) respectively, using the method of Example 2 to prepare α-GP enzyme solution, PGM enzyme solution, and PGI enzyme solution respectively, and using the BCA protein content detection kit to detect the target protein content, respectively α-GP Enzyme solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com