Method for preparing oxygen sensitive film of dissolved oxygen sensor by loading fluorescent indicator and application of oxygen sensitive film

A dissolved oxygen sensor and fluorescent indicator technology, which is applied in the direction of fluorescence/phosphorescence, instruments, scientific instruments, etc., can solve the problems of weak interaction between fluorescent indicators and substrates, loss of fluorescent indicators, slow response speed, etc., and achieve relief Loss of fluorescent indicator, improved mechanical strength, reduced impact and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

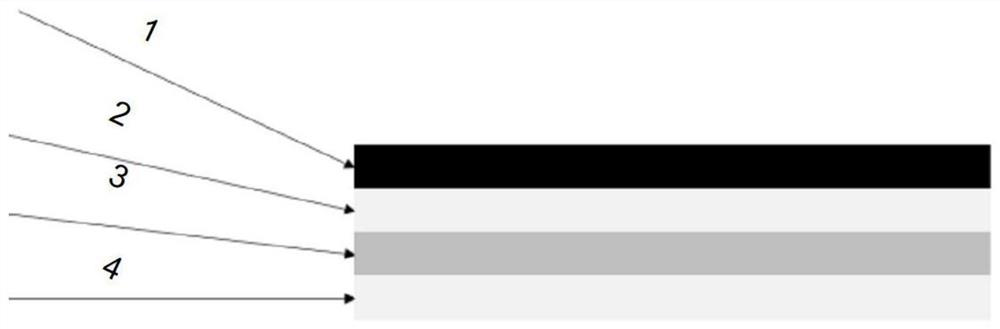

[0042] S1: Activation treatment of the transparent support layer 4: use a rotary low-temperature plasma surface treatment machine to activate the transparent support layer 4;

[0043] S2: the preparation of fluorescent layer 3: platinum (II) MESO-tetrakis (pentafluorobenzene) porphine and nano-alumina content ratio 1%, nano-alumina content 5% in fluorescent layer 3, nano-alumina and platinum ( Ⅱ) MESO-tetrakis(pentafluorobenzene) porphine, polydimethylsiloxane and n-hexane were mixed and ultrasonically treated for 30 minutes, then stirred for 12 hours to obtain the fluorescent layer slurry, and then the fluorescent layer slurry was coated with a spin coater Uniform coating on the transparent support layer 4 of S1 with a coating thickness of 50 μm to form a fluorescent layer 3;

[0044] S3: Preparation of the refraction layer 2: the content of nano-boron nitride in the refraction layer 2 is 5%, and the nano-boron nitride, polydimethylsiloxane and n-hexane are mixed and ultrason...

Embodiment 2

[0047] S1: Activation treatment of the transparent support layer 4: use a rotary low-temperature plasma surface treatment machine to activate the transparent support layer 4;

[0048] S2: the preparation of fluorescent layer 3: platinum (II) MESO-tetrakis (pentafluorobenzene) porphine and nano-alumina content ratio 3%, nano-alumina content 3% in fluorescent layer 3, nano-alumina and platinum ( Ⅱ) MESO-tetrakis(pentafluorobenzene)porphine, polydimethylsiloxane and n-heptane were mixed and ultrasonically treated for 30 minutes, then stirred for 12 hours to obtain a fluorescent layer slurry, and then the fluorescent layer slurry was coated with a spin coater Coating evenly on the transparent support layer 4 of S1 with a coating thickness of 60 μm to form a fluorescent layer 3;

[0049] S3: Preparation of refraction layer 2: the content of nano-boron nitride in refraction layer 2 is 7%, nano-boron nitride, polydimethylsiloxane and n-heptane are mixed, ultrasonically treated for 30...

Embodiment 3

[0052] S1: Activation treatment of the transparent support layer 4: use a rotary low-temperature plasma surface treatment machine to activate the transparent support layer 4;

[0053] S2: the preparation of fluorescent layer 3: platinum (II) MESO-tetrakis (pentafluorobenzene) porphin and nano-alumina content ratio 5%, nano-alumina content 6% in fluorescent layer 3, nano-alumina and platinum ( Ⅱ) MESO-tetrakis(pentafluorobenzene) porphine, polydimethylsiloxane and cyclohexane were mixed and ultrasonically treated for 30 minutes, then stirred for 12 hours to obtain a fluorescent layer slurry, and then the fluorescent layer slurry was coated with a spin coater Coating evenly on the transparent support layer 4 of S1 with a coating thickness of 15 μm to form a fluorescent layer 3;

[0054] S3: Preparation of the refraction layer 2: the content of nano-boron nitride in the refraction layer 2 is 10%, the nano-boron nitride, polydimethylsiloxane and cyclohexane are mixed, ultrasonical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com