Functional mesoporous material embedded with nanoparticles, in-situ embedding assembly method and application thereof

A technology of mesoporous materials and nanoparticles, which is applied in the field of material preparation, can solve the problems of difficulty in controlling the size, composition and shape of nanoparticles, and difficulty in establishing structure-activity relationships, etc., and achieve high utilization efficiency, strong accessibility, and high ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

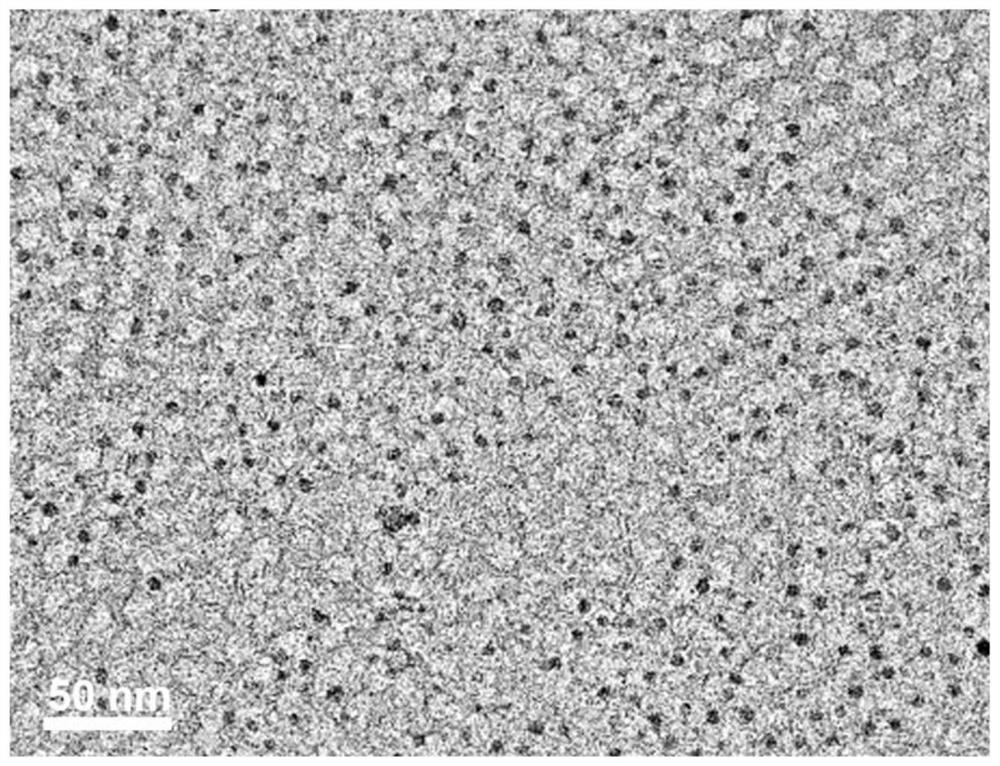

[0043] Add 0.10 g of F127 (surfactant) into 5.0 mL of tetrahydrofuran, and stir at room temperature for 30 min to obtain a clear and transparent solution. Then, 0.50 g of phenolic resin and 3.0 mg of iron ferric oxide nanoparticles with a size of about 4.5 nm were added to the above transparent solution, and the stirring was continued for 30 min. The mixed solution was then transferred to a glass petri dish (20x20cm 2 , add about 1.5mL solution to each petri dish), volatilize at room temperature for 8h to evaporate tetrahydrofuran, and then put it into an ordinary oven to continue curing at 100°C for 24h. The obtained film was scraped off from the petri dish, and then placed in a tube furnace for carbonization at 500°C for 4 hours under the protection of nitrogen to obtain a functionalized mesoporous carbon material embedded with Fe3O4 nanoparticles.

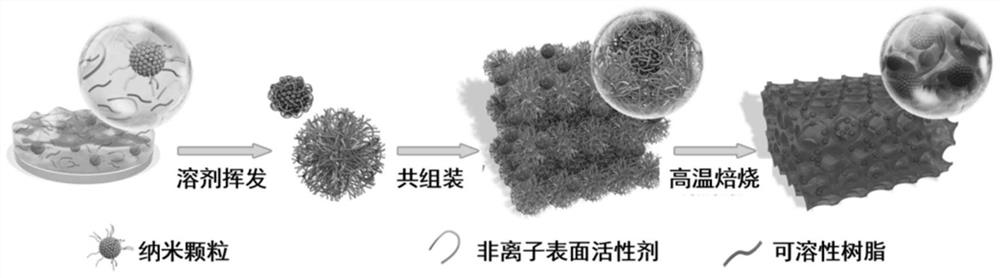

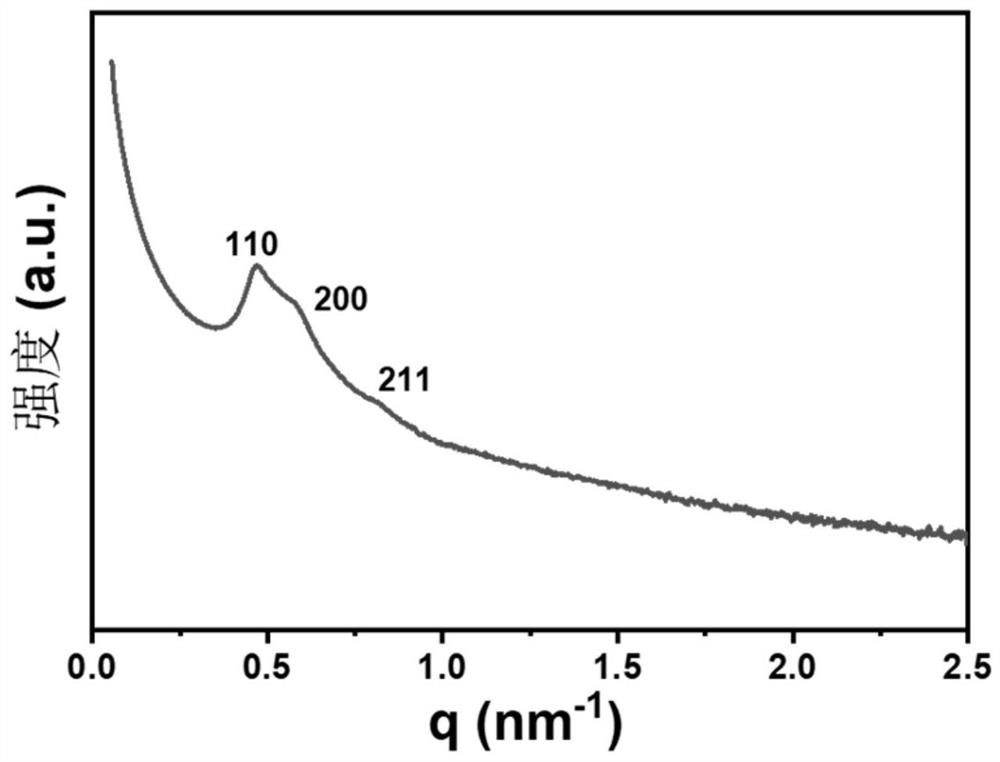

[0044] See figure 1 , in the present embodiment with surfactant Pluronic F127 (EO 106 -PO 70 -EO 106 ) as a template, pheno...

Embodiment 2

[0050] 0.10g of F127 was added to 5.0mL of tetrahydrofuran and stirred at room temperature for 30min to obtain a clear and transparent solution. Then, 0.50 g of phenolic resin and 10 mg of iron ferric oxide nanoparticles with a size of about 4.5 nm were added to the above transparent solution, and the stirring was continued for 30 min. The mixed solution was then transferred to a glass petri dish (20x20cm 2 , add about 1.5mL solution to each petri dish), volatilize at room temperature for 8h to evaporate tetrahydrofuran, and then put it into an ordinary oven to continue curing at 100°C for 24h. The obtained film was scraped off from the petri dish, and then placed in a tube furnace for carbonization at 500°C for 4 hours under the protection of nitrogen to obtain a functionalized mesoporous carbon material embedded with high-concentration Fe3O4 nanoparticles.

[0051] Figure 6 It is the transmission electron microscope image of the functionalized mesoporous carbon material i...

Embodiment 3

[0053] 0.10g of F127 was added to 5.0mL of tetrahydrofuran and stirred at room temperature for 30min to obtain a clear and transparent solution. Then, 0.50 g of phenolic resin and 2.0 mg of palladium nanoparticles with a size of about 3.0 nm were added to the above transparent solution, and the stirring was continued for 30 min. The mixed solution was then transferred to a glass petri dish (20x20cm 2 , add about 1.5mL solution to each petri dish), volatilize at room temperature for 8h to evaporate tetrahydrofuran, and then put it into an ordinary oven to continue curing at 100°C for 24h. The obtained film was scraped off from the petri dish, and then placed in a tube furnace for carbonization at 500° C. for 4 h under the protection of nitrogen to obtain a functionalized mesoporous carbon material embedded with palladium nanoparticles.

[0054] Figure 7 It is a transmission electron microscope image of the functionalized mesoporous carbon material inlaid with palladium nanop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com