Supported catalyst for preparing morpholine, and preparation method thereof

A supported catalyst and morpholine technology, which is applied in the preparation of supported catalysts for morpholine and its preparation field, can solve the problems of poor catalyst stability, low product purity, and low morpholine yield, and achieve uniform dispersion and high product purity , good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of catalyst and agent:

[0027] S1 Ball mill alumina, aluminum-based chelating resin, cross-linking agent, monomer and water to form a slurry, add polyurethane foam particles and catalyst to the slurry, stir evenly, pour it into a mold to solidify; then set it at a certain temperature Sintering to obtain the base material;

[0028] S2: dissolving the organic ligands in a solvent to obtain an organic ligand solution, immersing the substrate obtained in the above step S1 into the organic ligand solution, and soaking at a certain temperature for 24-72 hours to obtain the porous carrier;

[0029] S3: preparing a nitric acid solution containing active components, soaking the porous carrier prepared in step S2 into the solution, and drying to obtain the catalyst.

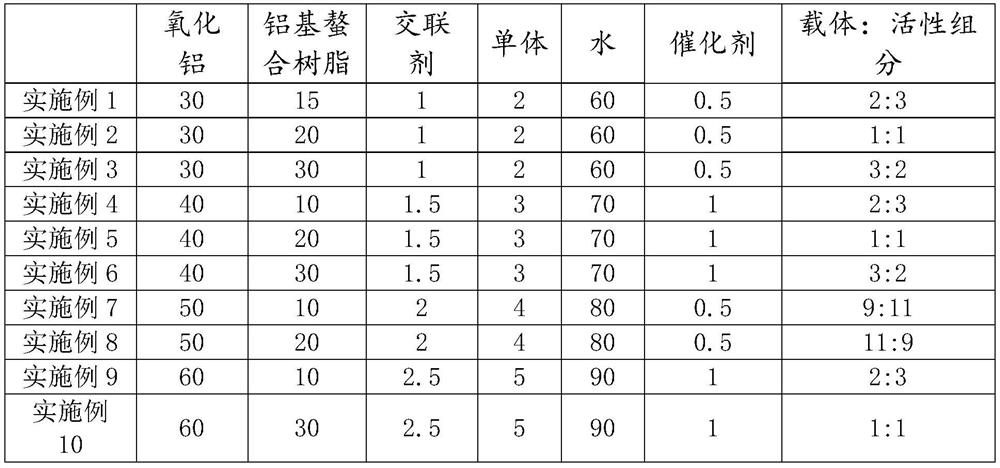

[0030] Catalysts No. 1-10 were prepared according to the above-mentioned preparation method and the ratio of raw materials in Table 1.

[0031] Table 1 embodiment 1-10 catalyst raw material ratio

[...

experiment example

[0044] In the reactants prepared in Examples 1-10 and Comparative Examples 1-3, the purity and yield of morpholine were measured, and the results are shown in Table 2.

[0045] The catalytic performance of the catalyst of table 2 embodiment 1-10 and comparative example 1-3

[0046] Example 1 Example 2 Example 3 Example 4 Example 5 Diethylene glycol conversion rate (%) 99.1 98.4 97.8 96.3 97.9 Morpholine yield (%) 90.2 90.5 89.5 88.4 90.2 Example 6 Example 7 Example 8 Example 9 Example 10 Diethylene glycol conversion rate (%) 99.4 98.3 98.1 98.5 99.1 Morpholine yield (%) 93.4 93.8 94.5 94.3 98.7 Comparative example 1 Comparative example 2 Comparative example 3 / / Diethylene glycol conversion rate (%) 80.2 82.4 83.4 / / Morpholine yield (%) 88.1 87.2 86.3 / /

[0047] As can be seen from Table 3, the catalyzer of the embodiment of the present invention 1-10 is applied t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com