Collecting agent and preparation method and application thereof

A collector and formula technology, applied in the field of collectors and their preparation, can solve the problems of weak collection capacity, low concentrate grade, low recovery rate, etc., and achieve simple preparation process, wide source of raw materials, high collection capacity strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

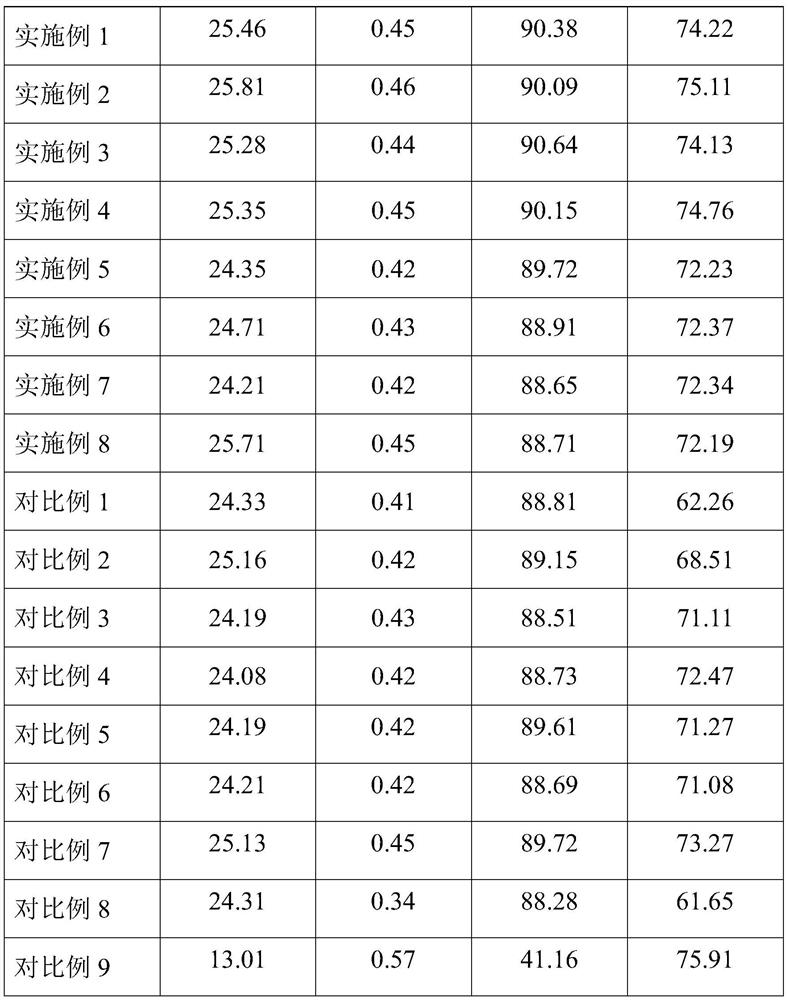

Examples

Embodiment 1

[0036] The invention provides a collector, which includes 72 parts of N,N-diethyldithiocarbamate propionitrile, 8 parts of methyl isobutyl carbinol, 1 part of alkylphenol polyoxyethylene ether (NP-10) and 23 parts diesel.

[0037] The invention provides a kind of preparation method of collector, and concrete steps are as follows:

[0038] According to the formula quantity, after mixing N,N-diethyldithiocarbamate propionitrile, methyl isobutyl carbinol, and alkylphenol polyoxyethylene ether (NP-10) at normal temperature and pressure, add Diesel oil was stirred for 30 minutes to obtain the collector.

Embodiment 2

[0040] The invention provides a collector, which includes 70 parts of propionitrile N,N-diethyldithiocarbamate, 9 parts of methyl isobutyl carbinol, and 1.5 parts of alkylphenol polyoxyethylene ether (NP-10) and 25 parts diesel.

[0041] The invention provides a kind of preparation method of collector, and concrete steps are as follows:

[0042] According to the formula quantity, after mixing N,N-diethyldithiocarbamate propionitrile, methyl isobutyl carbinol, and alkylphenol polyoxyethylene ether (NP-10) at normal temperature and pressure, add Diesel oil was stirred for 20 minutes to obtain the collector.

Embodiment 3

[0044] The invention provides a collector, which includes 75 parts of N,N-diethyldithiocarbamate propionitrile, 10 parts of methyl isobutyl carbinol, 1 part of alkylphenol polyoxyethylene ether (NP-10) and 20 parts diesel.

[0045] The invention provides a kind of preparation method of collector, and concrete steps are as follows:

[0046] According to the formula quantity, after mixing N,N-diethyldithiocarbamate propionitrile, methyl isobutyl carbinol, and alkylphenol polyoxyethylene ether (NP-10) at normal temperature and pressure, add Diesel oil was stirred for 25 minutes to obtain the collector.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com