A fiber-reinforced thermoplastic resin-based composite material-metal sheet connector and its preparation method and application

A thermoplastic resin and composite material technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of restricting the use of thermoplastic composite materials, low interface bonding strength of connectors, etc., and achieve suitable batches. Production, high production efficiency, improved interface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention provides the preparation method of the fiber-reinforced thermoplastic resin matrix composite material-metal sheet connector according to the above technical solution, comprising the following steps:

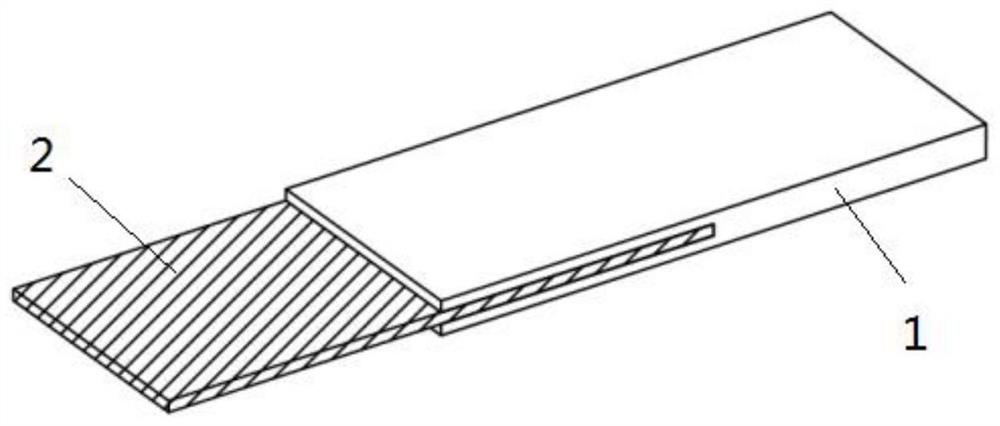

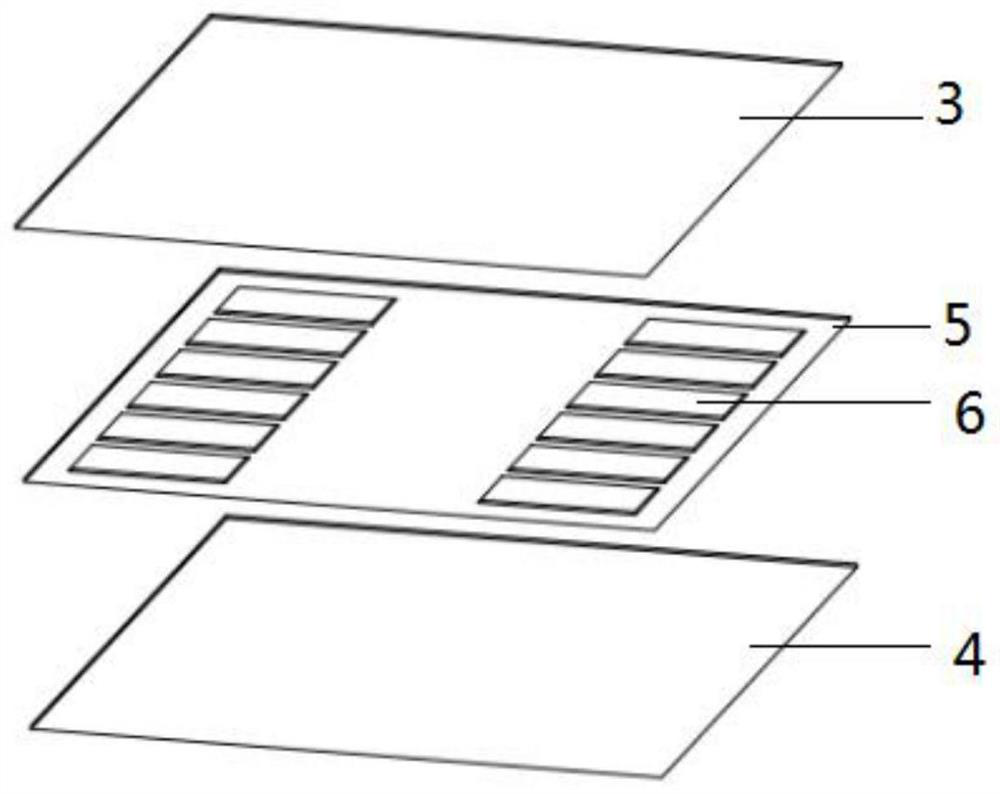

[0033] welding the hollow preform layer and the first preform layer, laying a metal sheet on the hollow part of the hollow preform layer, and then welding the hollow preform layer and the second preform layer, Obtaining a composite material embedded metal sheet pre-formed board;

[0034] The composite material-embedded metal sheet preform is hot-pressed and then cut to obtain a preform;

[0035] grinding the preform to obtain a fiber-reinforced thermoplastic resin matrix composite material-metal sheet connector;

[0036] The materials of the first preform layer, the hollow preform layer and the second preform layer are fiber-reinforced thermoplastic resin matrix composite materials.

[0037] In the present invention, unless otherwise specified, all ...

Embodiment 1

[0054] Carbon fiber reinforced PEEK resin matrix composite material - titanium alloy metal sheet connector

[0055] (1) Cut the carbon fiber reinforced PEEK resin matrix composite material with a thickness of 0.125mm into 16 pieces of composite material prepreg with a size of 300mm × 250mm, lay them up in a ±45° layup method, and then weld them to obtain a composite material containing 4 layers First preform layer of prepreg (thickness 0.5mm), second preform layer (thickness 0.5mm) containing 4 layers of composite prepreg, shaped body containing 8 layers of composite prepreg layer (1mm thickness).

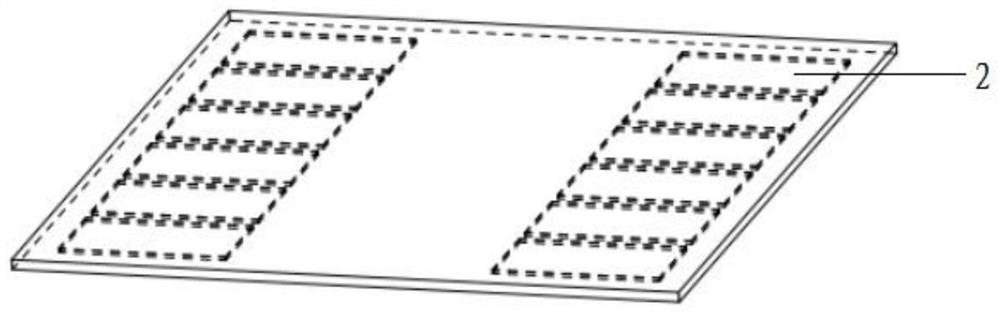

[0056] (2) Cut and hollow out the formed body layer containing 8 layers of composite material prepreg to obtain a hollowed out preformed body layer, weld the hollowed out preformed body layer and the first preformed body layer, and lay titanium alloy metal sheets on the hollowed out parts , welding the second preform layer to obtain a composite material embedded metal sheet prefor...

Embodiment 2

[0060] Glass fiber reinforced PPS resin matrix composite material - titanium alloy metal sheet connector

[0061] (1) Cut the glass fiber reinforced PPS resin-based composite material with a thickness of 0.125mm into 28 pieces of composite material prepregs with a size of 350mm × 350mm, lay them up according to the quasi-isotropic layering method, and then weld them to obtain 8 layers First preform layer of composite prepreg (thickness 1mm), second preform layer (thickness 1mm) containing 8 layers of composite prepreg, shaped body containing 12 layers of composite prepreg layer (1.5mm thickness).

[0062] (2) Cut and hollow out the formed body layer containing 12 layers of composite material prepreg to obtain a hollowed out preformed body layer, weld the hollowed out preformed body layer and the first preformed body layer, and lay titanium alloy metal sheets on the hollowed out parts , weld the second preform layer to obtain a composite material embedded metal sheet preform; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com