Compound for pre-lithiation, preparation method of compound, positive electrode pre-lithiation material, preparation method of positive electrode pre-lithiation material and lithium battery

A compound and lithium battery technology, used in the field of energy storage, can solve the problems of poor air stability of binary lithium-containing compounds and difficult industrial application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] Some embodiments of the present application provide a method for preparing a compound for pre-lithiation, comprising the following steps:

[0062] Step S1, mixing the M source and the lithium source.

[0063] Further, when the M source is mixed with the lithium source, the mixing is carried out according to the molar ratio of metal element M:Li=y:[x*(1.2-0.8)].

[0064] In some embodiments of the present application, the M source and the lithium source are uniformly mixed or ground according to the molar ratio of metal element M: Li = y: [x*(1.2-0.8)] to obtain a mixture.

[0065] Further optionally, the M source and the lithium source are uniformly mixed or ground according to the molar ratio of metal element M:Li=y:[x*(1.15-0.85)] to obtain a mixture.

[0066] Exemplarily, the M source and the lithium source are in accordance with the metal element M: Li molar ratio = y: [x*1.0]; M: Li molar ratio = y: [x * 1.05]; M: Li molar ratio = y: [x*0.9]; uniformly mixed or g...

Embodiment 1

[0105] Step S1, preparing the positive electrode pre-lithiation material Li 5 NbO 5 .

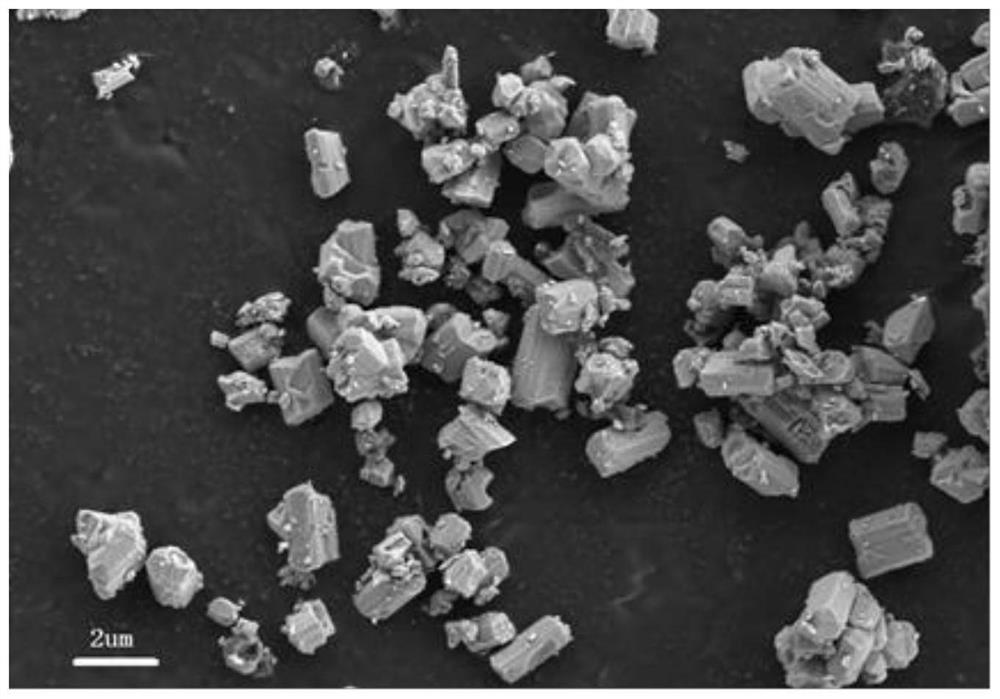

[0106] Weigh Nb 2 o 5 1g, LiOH·H 2 O 1.6g, mixed powder was obtained after mixing and grinding, and then the mixed powder was sintered at 900°C for 10 hours to prepare the positive electrode pre-lithiated material Li 5 NbO 5 , scanning electron microscope picture as figure 1 shown.

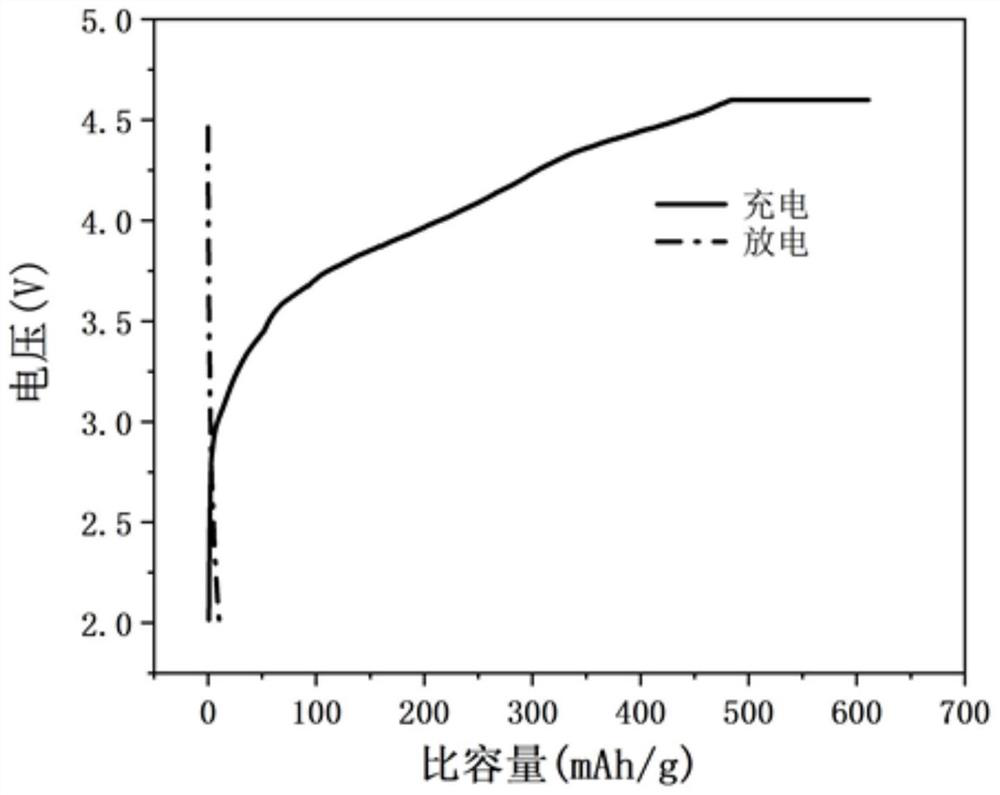

[0107] Step S2, detecting the positive electrode pre-lithiated material Li 5 NbO 5 When used as a positive pole piece, the lithium battery charge and discharge performance.

[0108] 0.7g of Li prepared in step S1 5 NbO 5 Mix with 1.5g of carbon black and 1.5g of PVDF, add 1g of NMP (N-methylpyrrolidone) to make a slurry, coat and dry to assemble the battery. Wherein, the electrolyte formula is 1M LiPF6 EC / DMC, and 1wt% vinylene carbonate is added in the electrolyte. The charge and discharge curve of the battery test is as follows: figure 2 and as shown in Table 1, Li 5 NbO 5 Charge specific ca...

Embodiment 2

[0119] Step S1, preparing the positive electrode pre-lithiation material Li 8 Nb 2 o 9 .

[0120] Weigh Nb 2 o 5 1g, LiOH·H 2 O 1.3g, mixed powder was obtained after mixing and grinding, and then the mixed powder was sintered at 900°C for 10 hours to prepare the positive electrode pre-lithiated material Li 8 Nb 2 o 9 .

[0121] Step S2, detecting the positive electrode pre-lithiated material Li 8 Nb 2 o 9 When used as a positive pole piece, the lithium battery charge and discharge performance.

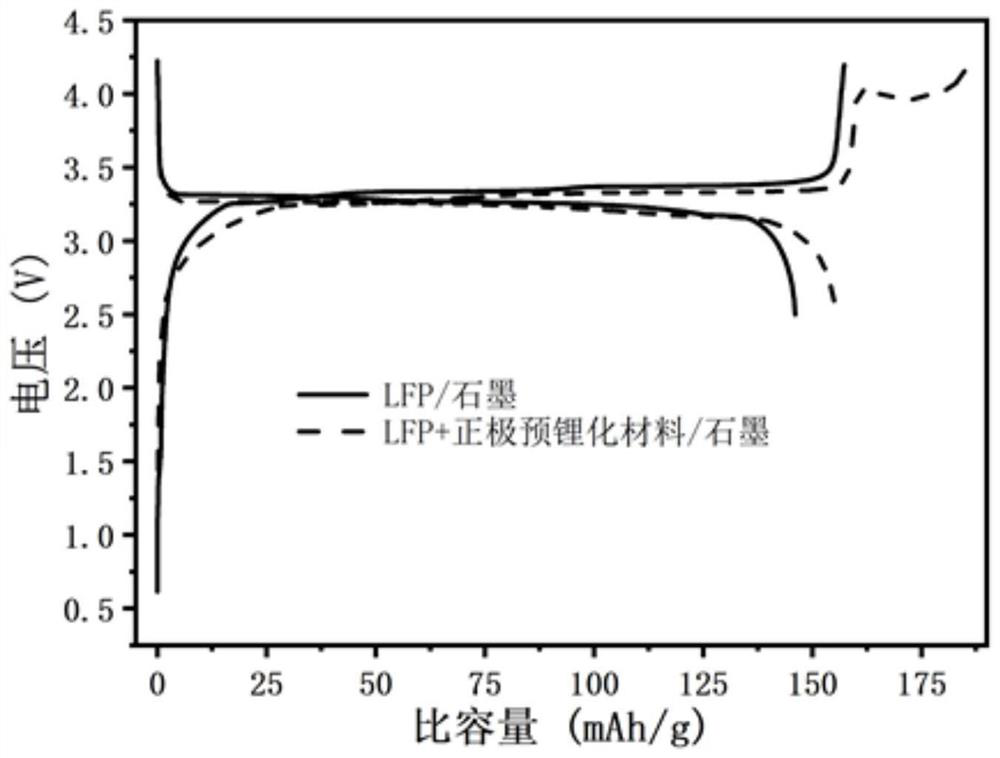

[0122] Mix 0.7g of the positive electrode pre-lithiated material prepared in step S1 with 1.5g of carbon black and 1.5g of PVDF, add 1g of NMP (N-methylpyrrolidone) to make a slurry, coat and dry to assemble the battery. Wherein, the electrolyte formula is 1M LiPF6 EC / DMC, and 1wt% vinylene carbonate is added in the electrolyte. The battery was tested for charging and discharging, and the test results are shown in Table 2. Step S3, detecting that the positive electrode p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com