Continuous preparation method and system of dibenzoyl methane

A technology of dibenzoylmethane and methyl benzoate, which is applied in the field of continuous preparation method and system of dibenzoylmethane, can solve the problems of low technical yield, large consumption of raw materials, high production cost, etc., and shorten the reaction time Time, reaction process, environmental protection, and the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

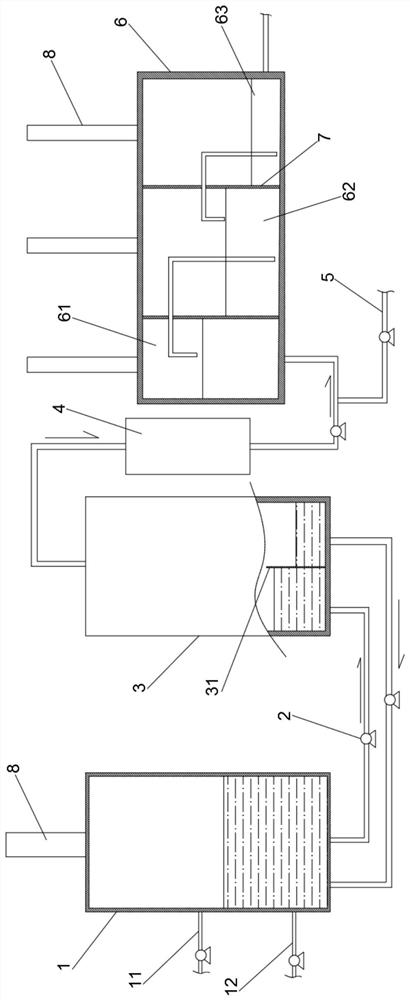

Image

Examples

Embodiment 1

[0025] Using benzoic acid and methanol as raw materials, the ratio of the amount of benzoic acid to methanol is 1:4, and the esterification reaction is carried out under the catalysis of the composite catalyst p-toluenesulfonic acid and concentrated sulfuric acid at 110 °C for 5 hours. After the reaction, Rectification obtains methyl benzoate; wherein the quality of p-toluenesulfonic acid is 5% of the concentrated sulfuric acid quality, and the addition of composite catalyst is 2% of the total mass of benzoic acid and methanol.

[0026] Then, methyl benzoate is directly mixed with the xylene solution containing acetophenone and sodium methylate, wherein the ratio of the amount of methyl benzoate to acetophenone is 3:1, and the acetophenone in the xylene solution The concentration of sodium methoxide and sodium methoxide is 53wt% and 1.6wt%. After mixing, Claisen condensation reaction is carried out. The reaction goes through three gradient temperature reactions of 8°C, 130°C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com