A linear actuator with layered microphase structure and its preparation method

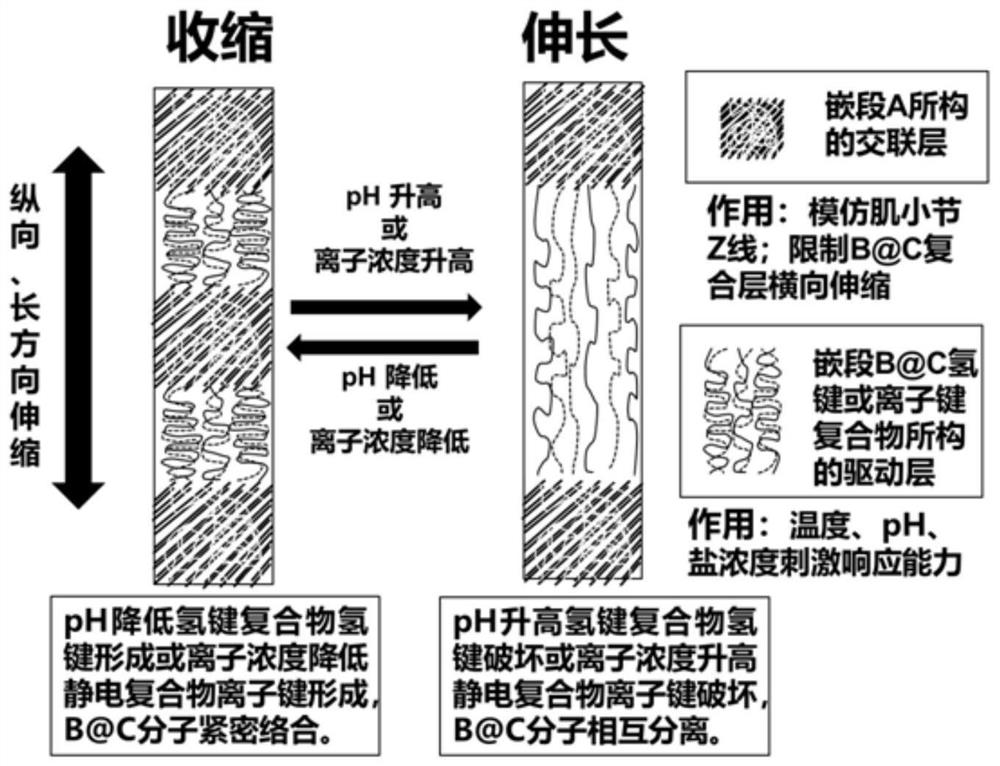

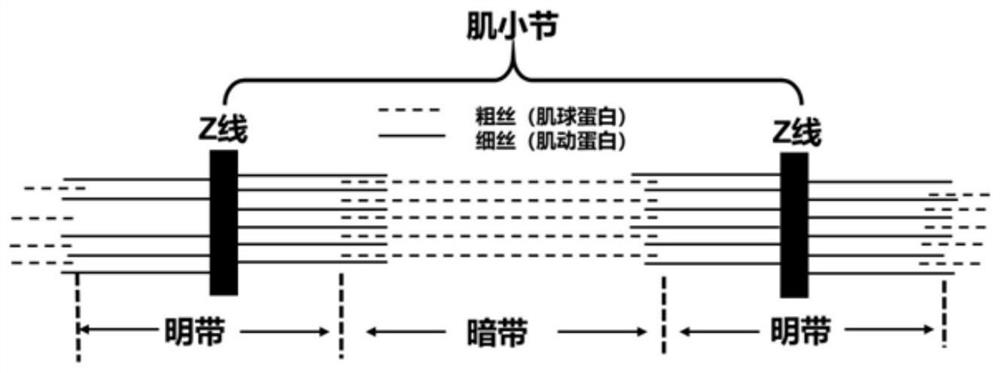

A linear actuator and micro-phase technology, applied in the field of actuators, can solve the problems of small expansion ratio of the actuator, inability to perform circular work, and inability to imitate the layered structure of sarcomeres.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

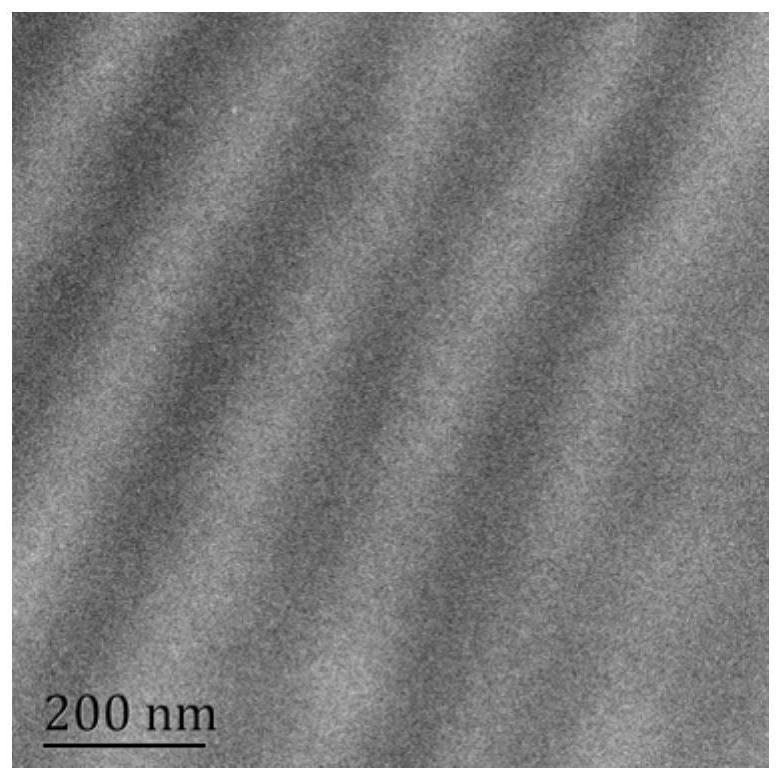

Examples

Embodiment 1

[0069] A preparation method of a linear actuator with a layered microphase structure, the specific steps are as follows:

[0070] (1) Preparation of raw materials;

[0071] Block copolymer X (ABA type triblock copolymer, i.e. K-3 in Table 1);

[0072] Block copolymer Y (ACA type tri-block copolymer, i.e. S-3 in Table 2);

[0073] (2) Dissolve block copolymer X in DMF to obtain solution I, and dissolve block copolymer Y in DMF to obtain solution II with the same concentration as solution I, then mix solution I and solution II to make a mixed solution , in the mixed solution, the mass percentage of block copolymer X is 10%, and the mass percentage of block copolymer Y is 10%; the mixed solution is processed into a film as a casting solution, and after drying, the film is soaked in a pH equal to 1 solution (hydrochloric acid solution) for 12h, take it out and then cut it into a spline, and carry out micro-stretching treatment on the spline along the length direction, and the st...

Embodiment 2

[0079] A preparation method of a linear actuator with a layered microphase structure, the specific steps are as follows:

[0080] (1) Preparation of raw materials;

[0081] Block copolymer X (ABA type tri-block copolymer, i.e. K-4 in Table 1);

[0082] Block copolymer Y (ACA type triblock copolymer, i.e. S-4 in Table 2);

[0083] (2) Dissolve block copolymer X in DMF to obtain solution I, and dissolve block copolymer Y in DMF to obtain solution II with the same concentration as solution I, then mix solution I and solution II to make a mixed solution , in the mixed solution, the mass percentage of block copolymer X is 2%, and the mass percentage of block copolymer Y is 2%; the mixed solution is processed into a film as a casting solution, and after drying, the film is soaked in a pH equal to 1 solution (hydrochloric acid solution) for 12h, take it out and then cut it into splines, carry out micro-stretching treatment on the splines along the length direction, the tensile elon...

Embodiment 3

[0089] A preparation method of a linear actuator with a layered microphase structure, the specific steps are as follows:

[0090] (1) Preparation of raw materials;

[0091] Block copolymer X (ABA type tri-block copolymer, i.e. K-5 in Table 1);

[0092] Block copolymer Y (ACA type tri-block copolymer, i.e. S-5 in Table 2);

[0093] (2) Dissolve block copolymer X in DMF to obtain solution I, and dissolve block copolymer Y in DMF to obtain solution II with the same concentration as solution I, then mix solution I and solution II to make a mixed solution , in the mixed solution, the mass percentage of block copolymer X is 10%, and the mass percentage of block copolymer Y is 10%; the mixed solution is processed into a film as a casting solution, and after drying, the film is soaked in a pH equal to 1 solution (hydrochloric acid solution) for 12h, take it out and then cut it into a spline, and carry out micro-stretching treatment on the spline along the length direction, and the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com