Method for nondestructive recovery of reinforcement in waste carbonyl-containing thermosetting resin under mild conditions

A reinforcement and thermosetting technology, applied in the field of degradation of polymer composite materials, can solve the problems of low efficiency and harsh waste recycling conditions, and achieve the effects of high resin removal rate, low requirements for reaction equipment, and mild degradation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

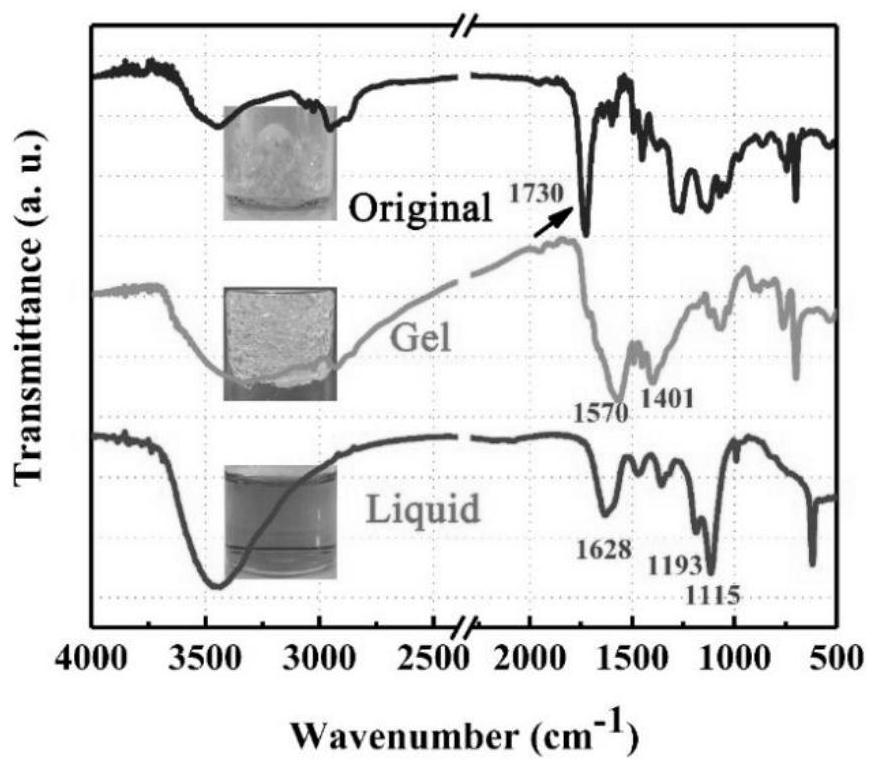

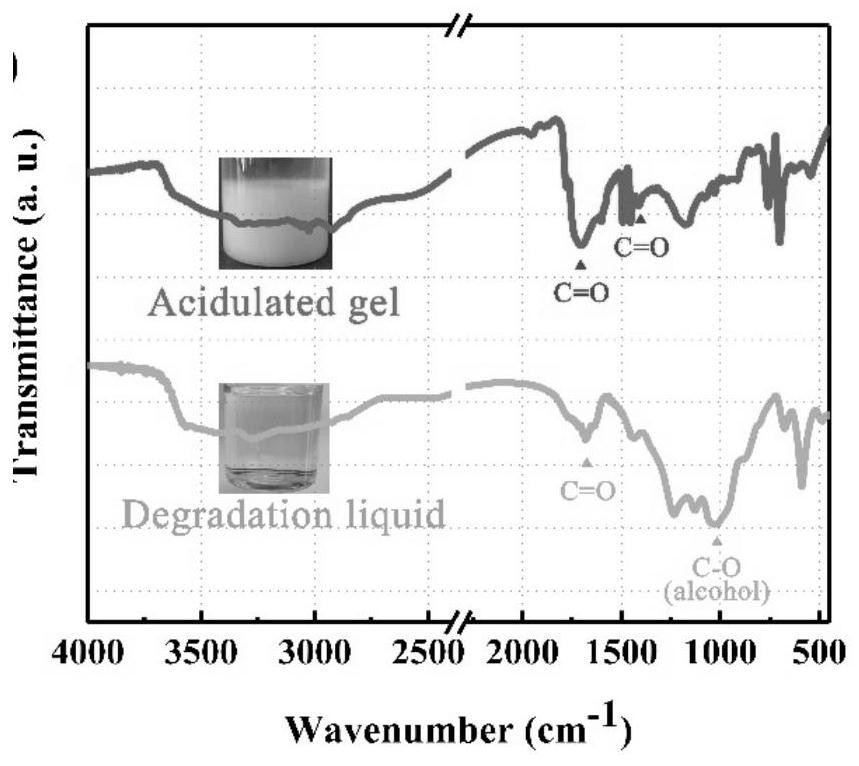

[0027] A method for recycling carbon fiber reinforcements from waste carbonyl-containing thermosetting resins, taking unsaturated polyester composite materials as an example, specifically includes the following steps: firstly, the waste unsaturated polyester composite materials are subjected to the first pretreatment, and the second The pretreated resin is mixed with an alkaline solution and heated to obtain a degradation product that can be further degraded.

[0028] Further, the above-mentioned first pretreatment method includes: mechanically cutting short and soaking in an alkaline solution, the alkaline solution includes an alkaline solvent and an alkaline substance, and the alkaline solvent includes but is not limited to Hydrazine and hydrazine derivatives, organic solutions of 2-hydroxyethylamine, 1,2-propylenediamine, 1,3-propylenediamine, 1,4-butylenediamine, diethylenetriamine, triethylenetetramine and water mixture. The alkaline substances include but are not limite...

Embodiment 1

[0042] Mechanically pulverize 20g of waste commercial unsaturated polyester to 20-40 mesh, weigh 1g of pulverized resin, add 3.9996g of NaOH and 4.86mL of 80% hydrazine hydrate solution to mix, heat to 80°C and continue to react for 2 hours to obtain degradation products, degradation products The solid product and the degradation solution were obtained by filtration. The solid product was dried at 80° C. for three days and weighed to measure 0.45 g. The calculated degradation rate was 55%.

Embodiment 2

[0044] Mechanically pulverize 20g of waste commercial unsaturated polyester to 20-40 mesh, weigh 1g of pulverized resin, add 2.6664g of NaOH and 6.48mL of 80% hydrazine hydrate solution to mix, heat to 80°C and continue to react for 2 hours to obtain degradation products, degradation products The solid product and the degradation solution were obtained by filtration. The solid product was dried at 80° C. for three days and weighed to measure 0.37 g. The calculated degradation rate was 63%.

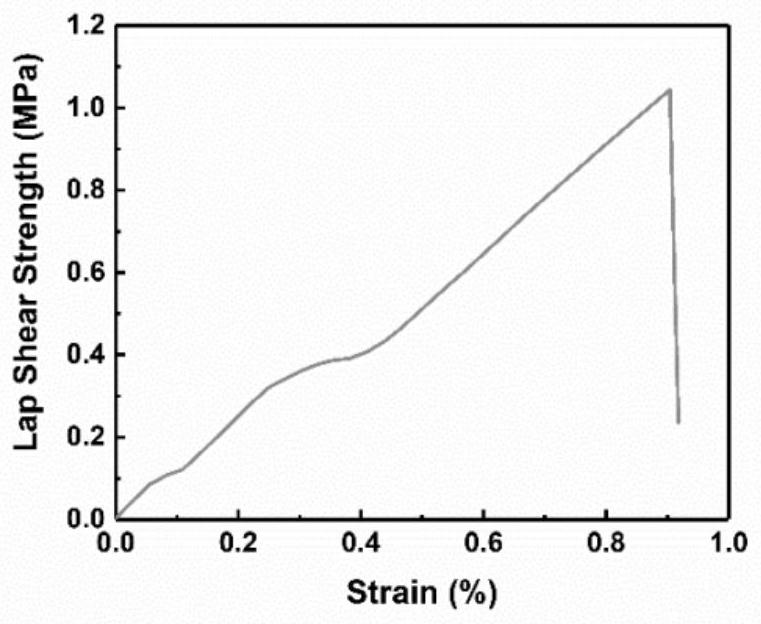

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com