Zero-discharge treatment process for abamectin production wastewater

A technology for the production of abamectin and waste water, which is applied in water/sewage treatment, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc. It can solve the problem that the treatment effect is not particularly ideal, the water outlet requirements cannot be met, and the residence time Long-term problems, to achieve the effect of resource utilization, less land occupation and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

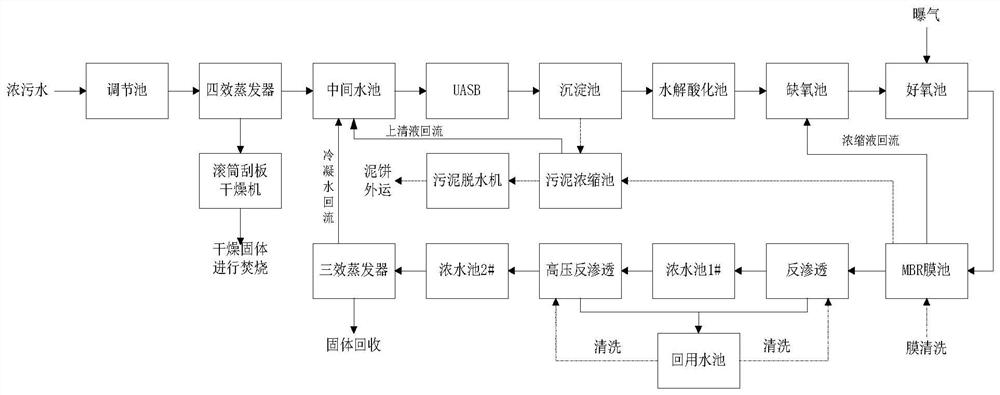

[0046] like figure 1 Shown, a kind of zero-discharge treatment process of Abamectin production waste water, comprises the steps:

[0047] (1) Collect the filtrate produced in the production process of the biopesticide abamectin into the adjustment tank, adjust the water quality and quantity, and adjust the pH of the waste water to 6-7 with acid or lye;

[0048] (2) Wastewater with stable water quality and quantity is first pumped into the four-effect evaporator by the feed pump, and evaporated by the large-flow forced circulation pump without stopping the heating cycle;

[0049] (3) The concentrated solution obtained after concentrating 10 times is sent to a dryer for further drying treatment, and the solid matter formed after drying is incinerated, and the evaporated condensate enters the intermediate pool;

[0050] (4) The condensate is pumped from the bottom of the UASB reactor after the water quality and quantity are stabilized in the intermediate pool. In the UASB reacto...

Embodiment 2

[0059] like figure 1 Shown, a kind of zero-discharge treatment process of Abamectin production waste water, comprises the steps:

[0060] (1) Collect the filtrate produced in the production process of the biopesticide abamectin into the regulating tank, adjust the water quality and quantity, and adjust the pH of the waste water to 6-7 with acid or lye.

[0061] (2) Wastewater with stable water quality and quantity is first pumped into the four-effect evaporator by the feed pump, and evaporated by the large-flow forced circulation pump without stopping the heating cycle;

[0062] (3) The concentrated solution obtained after being concentrated 20 times is sent to a drier for further drying treatment, and the solid matter formed after drying is carried out for incineration treatment, and the evaporated condensate enters the intermediate pool.

[0063] (4) The condensate is pumped from the bottom of the UASB reactor after the water quality and quantity are stabilized in the inter...

Embodiment 3

[0072] like figure 1 Shown, a kind of zero-discharge treatment process of Abamectin production waste water, comprises the steps:

[0073] (1) Collect the filtrate produced in the production process of the biopesticide abamectin into the adjustment tank, adjust the water quality and quantity, and adjust the pH of the waste water to 6-7 with acid or lye;

[0074] (2) Wastewater with stable water quality and quantity is first pumped into the four-effect evaporator by the feed pump, and evaporated by the large-flow forced circulation pump without stopping the heating cycle;

[0075] (3) The concentrated solution obtained after concentrating 30 times is sent to a drier for further drying treatment, and the solid matter formed after drying is incinerated, and the evaporated condensate enters the intermediate pool;

[0076] (4) The condensate is pumped from the bottom of the UASB reactor after the water quality and quantity are stabilized in the intermediate pool. In the UASB reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com