A multi-stage membrane separation device and method for treatment and reuse of fermentation wastewater

A technology for fermentation wastewater and treatment device, which is applied in water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. The effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

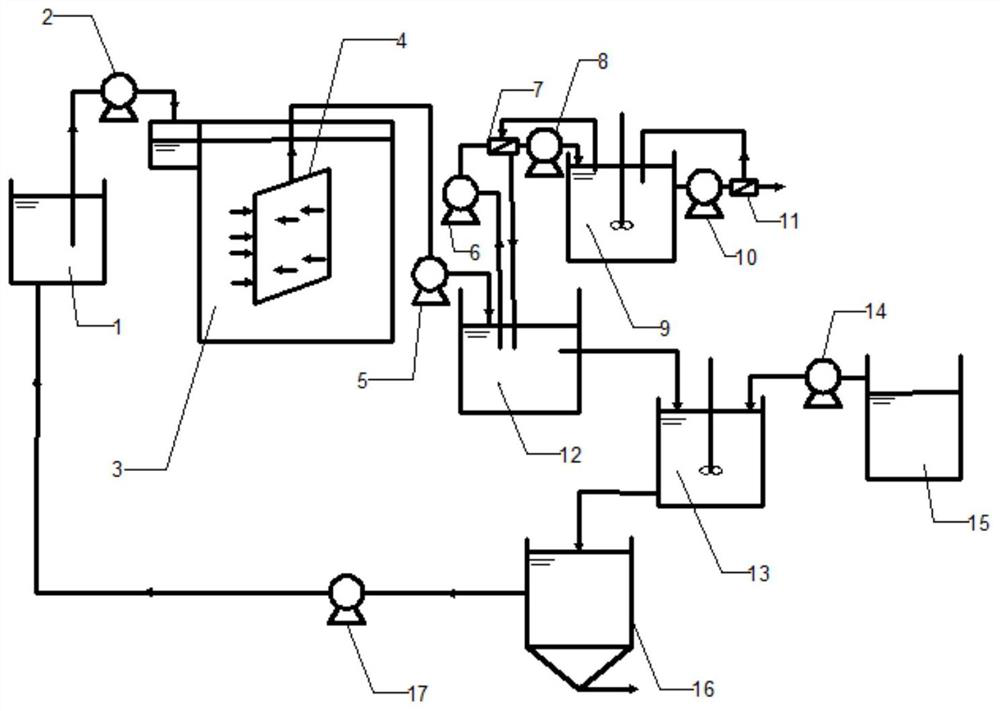

[0048] figure 1 It is a structural schematic diagram of an embodiment of the multi-stage membrane separation device of the present invention.

[0049] combine figure 1 Introducing the device of the present invention, a multi-stage membrane separation device for advanced treatment and reuse of fermented wastewater in this embodiment mainly includes an inlet pool 1, anaerobic reactor 3, FO membrane module 7, and a liquid extraction pool 9 , nanofiltration membrane treatment device 11, precipitation device 16; MF membrane module 4 is included in the anaerobic reactor 3 and MF membrane module 4 is connected with water outlet pool 12 by suction pump 5, and water outlet pool 12 is connected with FO membrane by FO water inlet pump 6 The concentrated water of the FO membrane module 7 is connected to the outlet pool 12 through pipelines; the FO membrane module 7 is connected to the draw solution pool 9 through the draw solution pump 8 and the pipeline, wherein the draw solution pump 8...

Embodiment 2

[0061] use as figure 1 A multi-stage membrane separation process with the structure shown. The treatment device operates at room temperature, the influent is artificially prepared simulated alcohol wastewater, and its water quality indicators are: COD: 3300mg / L, NH 3 -N: 80 mg / L, TP: 16 mg / L. Control the inlet water temperature to 35°C with a heating rod, and control the pH of AnMBR to 6.8-7.2 by adjusting the amount of sodium bicarbonate added in the inlet water preparation. The inoculum sludge used in AnMBR was taken from Wuxi Meicun Wastewater Treatment Plant. The sludge was first sieved to remove large solid particles such as gravel, and then inoculated into the reactor. The initial concentration of suspended solids (MLSS) in the inoculum mixture was 3 g / L. In the process of sludge domestication, only MF membrane is used, its flux is controlled at 5LMH, and the initial influent COD concentration is 500mg / L. When the COD removal rate of the reactor is greater than 70%, ...

Embodiment 3

[0067] use as figure 1 A multi-stage membrane separation process with the structure shown. The treatment device operates at room temperature, the influent is artificially prepared simulated alcohol wastewater, and its water quality indicators are: COD: 3300mg / L, NH 3 -N: 80 mg / L, TP: 16 mg / L. Control the inlet water temperature to 35°C with a heating rod, and control the pH of AnMBR to 6.8-7.2 by adjusting the amount of sodium bicarbonate added in the inlet water preparation. The inoculum sludge used in AnMBR was taken from Wuxi Meicun Wastewater Treatment Plant. The sludge was first sieved to remove large solid particles such as gravel, and then inoculated into the reactor. The initial concentration of suspended solids (MLSS) in the inoculum mixture was 3 g / L. In the process of sludge domestication, only MF membrane is used, its flux is controlled at 5LMH, and the initial influent COD concentration is 500mg / L. When the COD removal rate of the reactor is greater than 70%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com