Method for producing microalgae through utilizing livestock and poultry excrement primary wastewater

A livestock and poultry feces and primary technology, applied in the field of microalgae production, can solve complex and high-cost problems, achieve stable operation, increase biomass, and reduce cultivation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

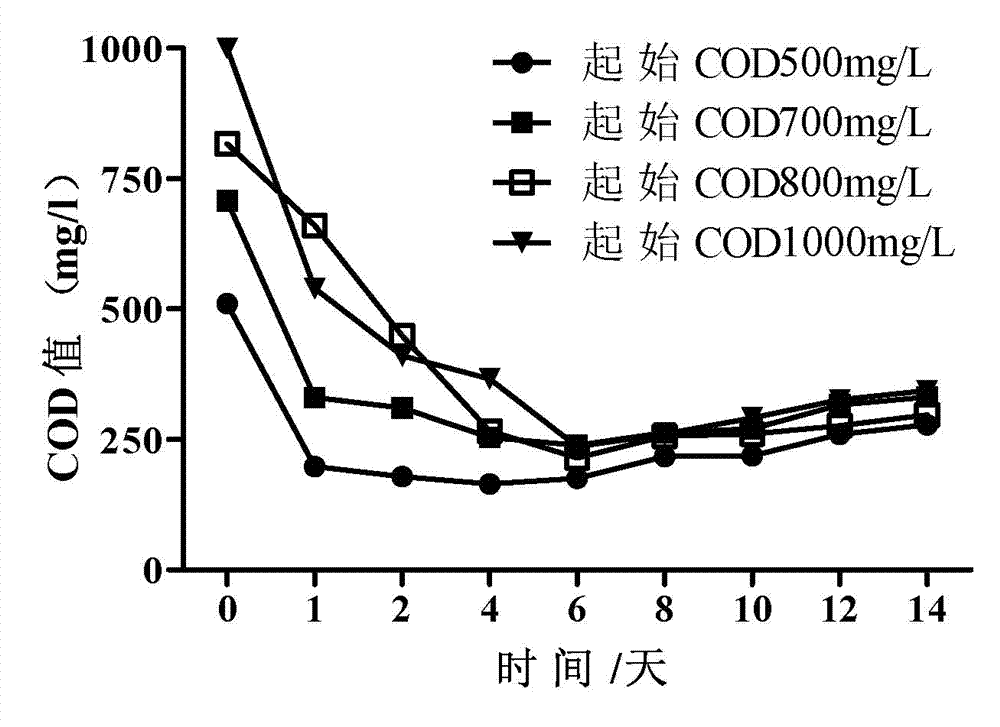

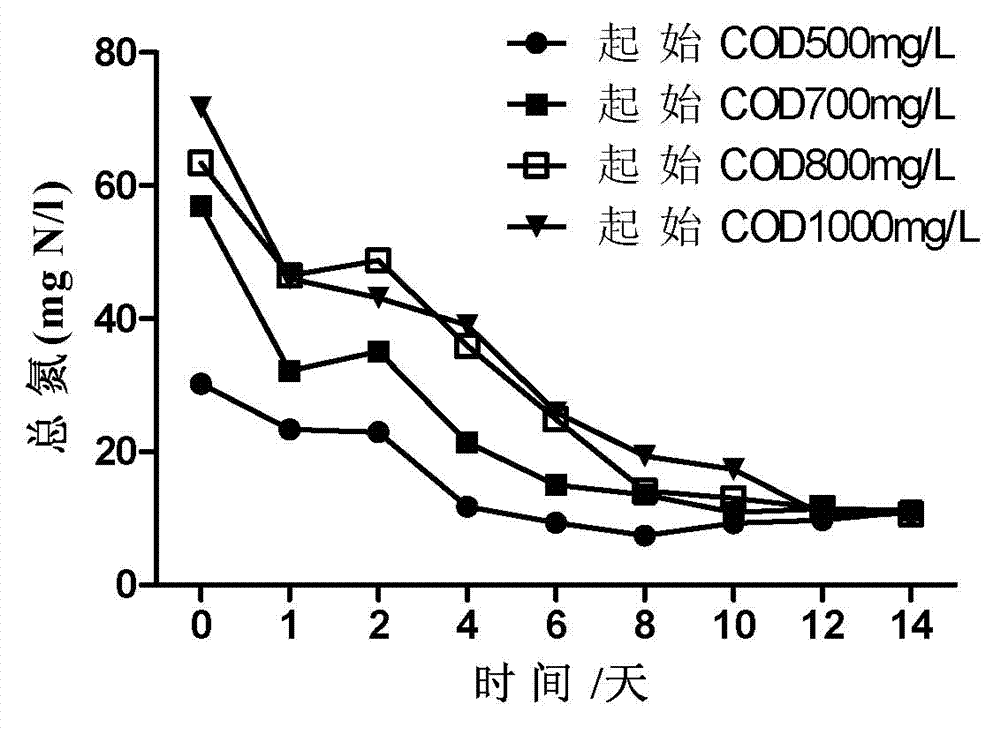

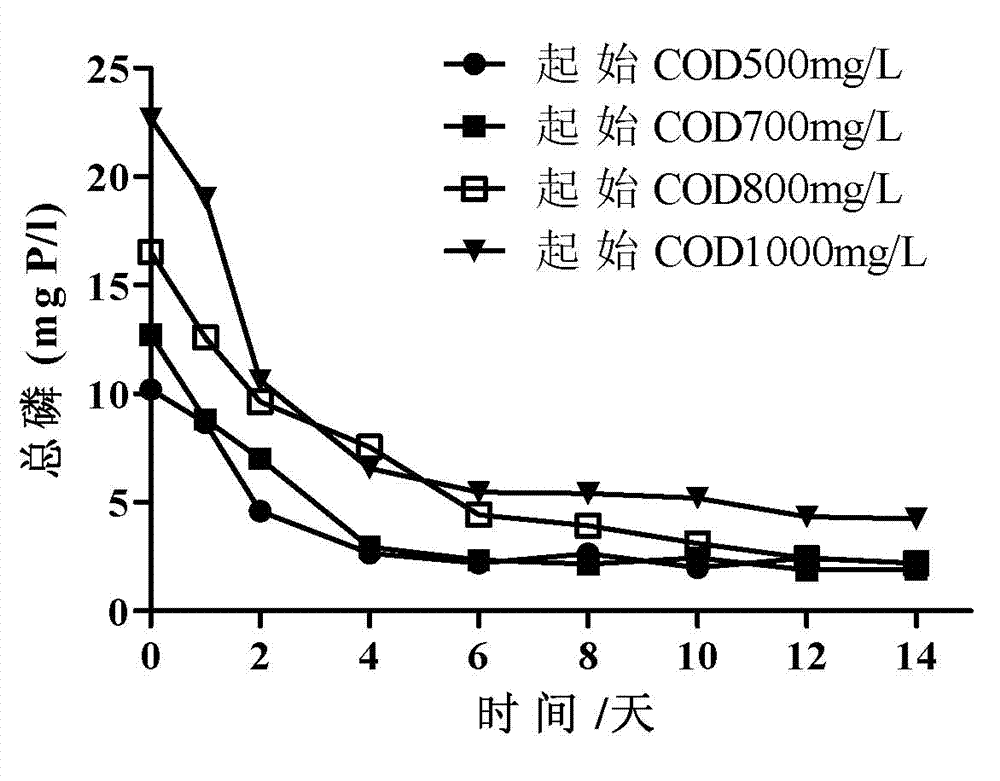

[0031] 1) The pretreatment method of pig manure primary wastewater: add flocculant chitosan and coagulant sodium alginate to pig manure primary wastewater at a ratio of 10g / L respectively, and carry out flocculation treatment, and the pH of flocculation is 5.0~7.0 between. The obtained supernatant pig manure primary waste liquid was diluted to the initial COD values of 500mg / L, 700mg / L, 800mg / L, and 1000mg / L respectively. Introduce ozone until its concentration reaches above 2.8mg / L, and the sterilization rate reaches above 97% after ozone treatment. Aeration reduces the ozone concentration in the liquid to 0.072mg / L.

[0032] 2) Microalgae culture: inoculate the chlorella cultured to the logarithmic growth phase into the liquid obtained in step 1 at an inoculation amount of 10%, and carry out aerated culture at a temperature of 25°C to 35°C. During the cultivation process, the air of 100mL / min L has been supplied by the air pump, and the introduction of carbon dioxide is ...

Embodiment 2

[0035] The pretreatment method of pig manure primary wastewater: add flocculant chitosan and coagulant sodium alginate to the pig manure primary wastewater at a ratio of 5 g / L, respectively, for flocculation treatment, and the pH of flocculation is between 5.0 and 7.0 between. The obtained supernatant pig manure primary waste liquid was diluted to an initial COD value of 800mg / L. Introduce ozone until its concentration reaches 2.58 mg / L, 2.86 mg / L, and 3.1 mg / L respectively, and test the sterilization rate.

[0036] Such as Figure 5 As shown, the sterilization rate is only about 60% after the ozone concentration is 2.58 mg / L, while the sterilization rate can reach more than 97% after the ozone concentration is 2.86 mg / L or 3.1 mg / L. For the principle of economy, the ozone sterilization of the present invention is preferably passed to an ozone concentration above 2.8mg / L.

Embodiment 3

[0038] 1) The pretreatment method of pig manure primary wastewater: add flocculant chitosan and coagulant sodium alginate to pig manure primary wastewater at a ratio of 8 g / L, respectively, for flocculation treatment, and the pH of flocculation is 5.0~ 7.0 between. The obtained supernatant pig manure was diluted to the initial COD value of 1000 mg / L respectively. Introduce ozone until its concentration reaches above 2.8mg / L, and the sterilization rate reaches above 97% after ozone treatment. Aeration reduces the ozone concentration in the liquid to below 0.1mg / L.

[0039] 2) Microalgae culture: Inoculate the chlorella cultured to the logarithmic growth phase into the liquid obtained in step 1 at an inoculum amount of 15%, and carry out aerated culture at a temperature of 25°C to 35°C. During the cultivation process, the gas has been fed in the following ways: a. Only the air pump is used to continuously feed the air; b. The mixed gas of carbon dioxide and air is continuously...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com