Oligodextrose and preparation method thereof

A glucose and oligomerization technology, applied in the field of oligosaccharides, can solve problems such as unfavorable commercial applications, achieve the effects of mature extraction technology, mild reaction conditions, and overcome low product concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

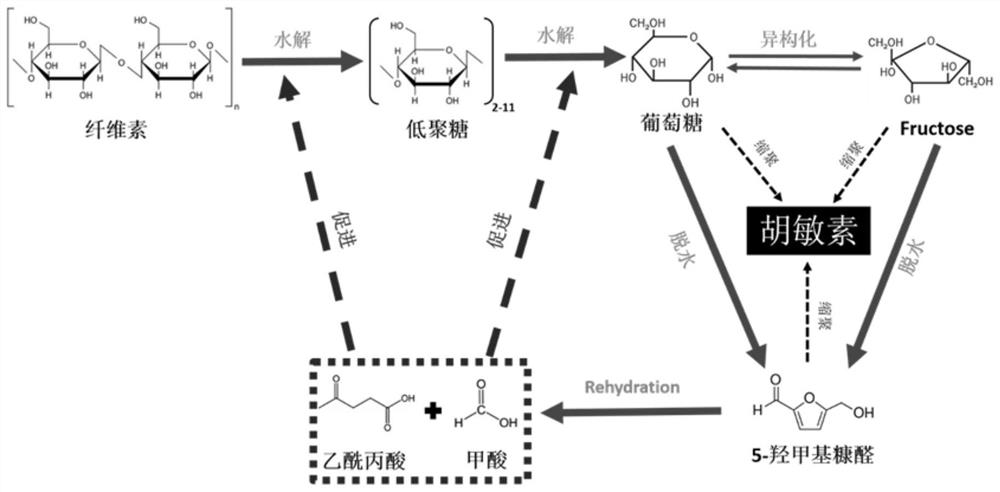

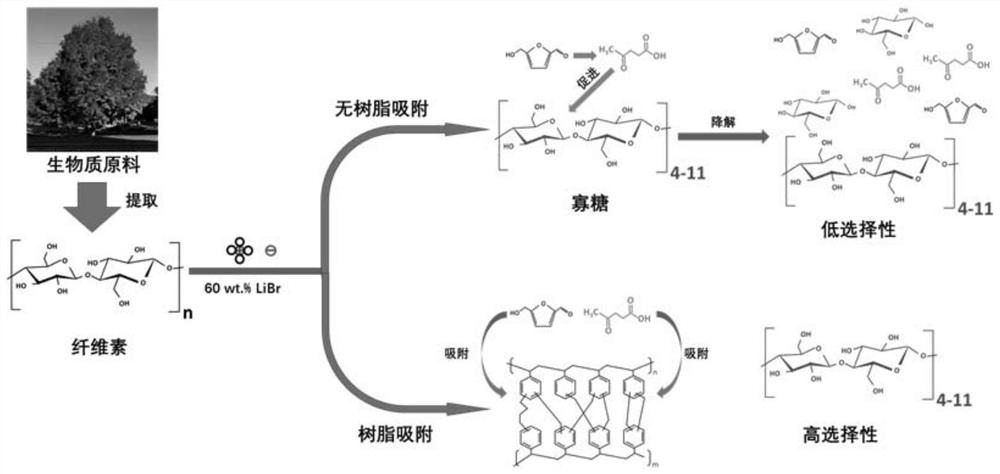

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Preparation of 60wt.% LiBr salt solution: 12g of water was added to 18g of anhydrous LiBr, and stirred until completely dissolved to obtain a 60wt.% lithium bromide solution.

[0040] The preparation method of highly cross-linked resin can refer to the literature (RSC Advances, 2020, 10, 34732-34737 and Macomolecules). g of azobisisobutyronitrile, 1g of gelatin, and 15g of polydimethyldiallylammonium chloride were added to 300mL of water, at 40°C, N 2 Stir in the atmosphere for 1 h to dissolve, then increase the temperature to 75°C, and react for 8 h. After the reaction was over, the resulting solid was washed with ethanol and then dried, and then 5g of solid, 40mL of dichloroethane, 2g of FeCl 3 Add it into a glass reaction bottle, stir at room temperature for 2 hours, then raise the temperature to 80°C, and react for 12 hours. After the reaction, the solid residue was obtained by filtration, washed 5 times with acetone containing 4wt.% hydrochloric acid concentratio...

Embodiment 1

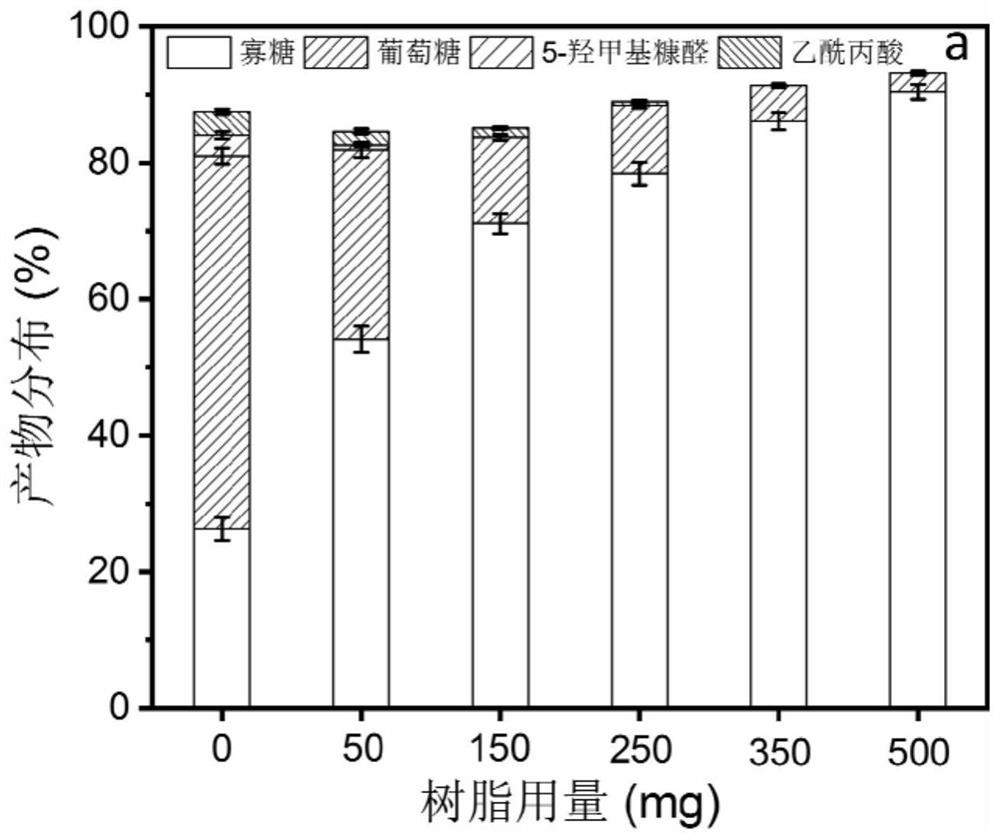

[0042] Weigh 500 mg of cellulose and a certain amount of highly cross-linked resin, put them into a thick-walled glass reaction tube with a volume of 15 mL, add 5 g of LiBr salt solution with a concentration of 60 wt.%, put them into an oil bath at 130 ° C, and take them out after 4 hours of reaction. Cooled in circulating water, quantitatively analyzed by liquid chromatography, the obtained results are as follows Figure 3a , Figure 3b shown.

[0043] Depend on Figure 3a , Figure 3b It can be seen that under mild conditions, cellulose can be directional converted into oligosaccharides. Along with the increase of resin dosage, the yield and concentration of oligosaccharides are gradually increased, and when the dosage ratio of resin and cellulose is from 0 to 1:1, oligosaccharide yield is promoted to 90.4% by 26.3% (see Figure 3a ), the oligosaccharide concentration increased from 42.1g / L to 144.6g / L (see Figure 3b ).

Embodiment 2

[0045]Take 500mg of cellulose and 250mg of resin, put them into a 15mL thick-walled glass reaction tube, add 5g of LiBr solution with a concentration of 60wt.%, mix them, put them into an oil bath at 130°C, take them out after reacting for different times, and cool them in circulating water , quantitatively analyzed by liquid chromatography, the results are as Figure 4 shown.

[0046] Depend on Figure 4 It can be seen that as the reaction time increases, more and more cellulose is converted into oligosaccharides. After 4 hours of reaction, the yield of oligosaccharides reaches 78.4%. Further prolonging the reaction time will cause the hydrolysis of oligosaccharides and reduce its yield. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com