Safe porous nickel catalyst activity recovering method

A technology of activity recovery and catalyst, which is applied in the direction of catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of catalyst structure change and the difficulty of realizing the activity recovery method, and achieve easy industrial scale-up, The effect of safe operation, easy storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

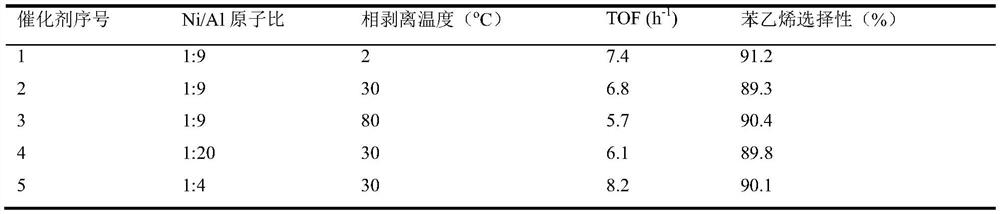

[0014] With different ratios of nickel and aluminum raw materials, it is smelted and crushed into 200-400 mesh metal powder (average particle size 50μm), and finally it is exfoliated by 0.5M NaOH to form a safe porous nickel catalyst. It was directly applied to evaluate the hydrogenation performance of phenylacetylene at room temperature and pressure, and the reaction performance is shown in Table 1.

[0015] Table 1

[0016]

Embodiment 2

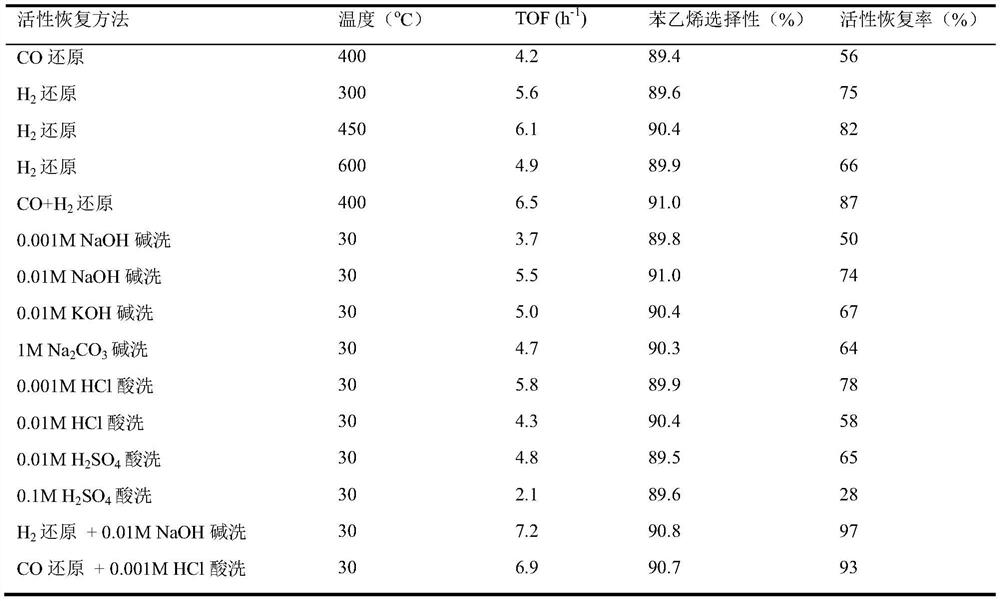

[0018] Select No. 1 catalyst, after vacuum drying, carry out the activity recovery experiment of different conditions, after recovery, carry out the hydrogenation performance evaluation of phenylacetylene at normal temperature and pressure, the reaction performance and activity recovery rate are as shown in Table 2 (after drying, after experiment , before the activity recovers, the conversion efficiency TOF of phenylacetylene is 0.4h -1 , Styrene selectivity 90.2%). The activity recovery rate is the ratio of the reaction performance data (Table 2 TOF) after the activity recovery treatment to the reaction performance data (Table 1 TOF) directly applied.

[0019] Table 2

[0020]

Embodiment 3

[0022] The No. 1 safety porous nickel catalyst prepared above is applied to the selective hydrogenation reaction of 1,4-butynediol at normal temperature and pressure (the concentration of 1,4-butynediol is 1wt%, water is a solvent, and the reaction 4h), the conversion rate is 72.6%, and the selectivity to 1,4-butenediol is 92.8%. If it is dried, the H 2 The conversion rate of 1,4-butynediol can reach 71.1% and the recovery rate of activity can reach 98% after the mixture of reduction at 400°C and 0.01M NaOH alkali washing for activation under atmosphere.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com