Silicon carbide ceramic matrix composite reflector and preparation method and application thereof

A technology of silicon carbide ceramic matrix and composite materials, applied in mirrors, instruments, optics, etc., can solve problems such as low strength, achieve low strength, overcome brittleness, and improve optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for preparing a silicon carbide ceramic matrix composite mirror, comprising the steps of:

[0045] The reflective surface and support structure of the reflector structure in this embodiment are processed from the same blank;

[0046] (1) Using continuous carbon fibers to prepare a three-dimensional needle-punched fiber preform according to the mirror structure model, the continuous fiber in the fiber preform accounts for 25 to 30% of the mirror surface of the silicon carbide ceramic matrix composite material;

[0047] (2) Put the fiber prefabricated body prepared in step (1) into the graphite mold for shaping, and put the graphite mold with the fiber prefabricated body into the reaction furnace, and use the first chemical vapor deposition process to complete the fiber prefabricated body interface preparation and SiC ceramic matrix preparation, to obtain a fiber-reinforced SiC ceramic matrix composite reflector blank;

[0048] (21) The interface preparation of ...

Embodiment 2

[0056] A method for preparing a silicon carbide ceramic matrix composite mirror, comprising the steps of:

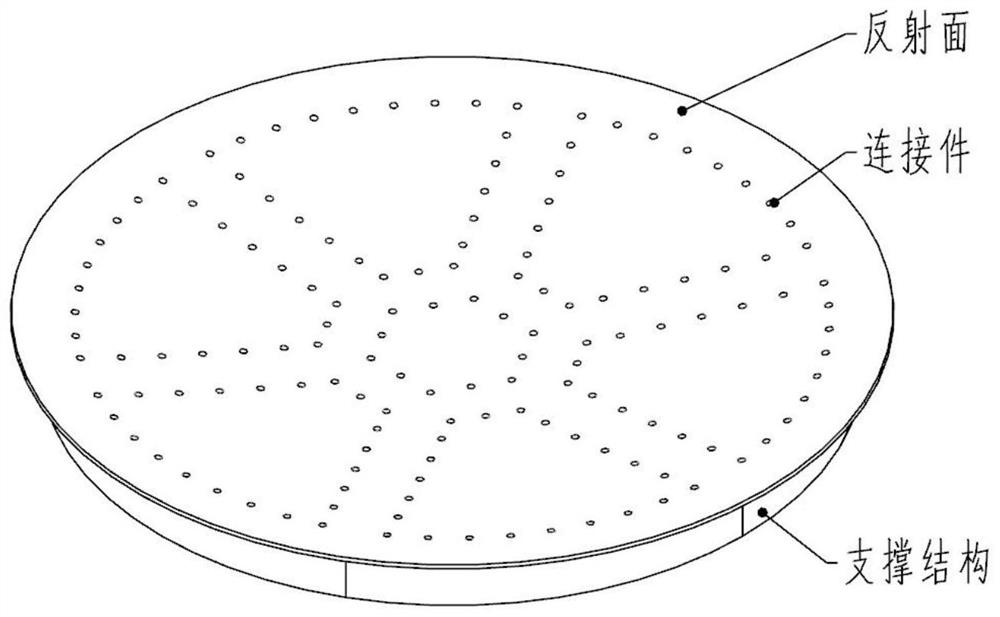

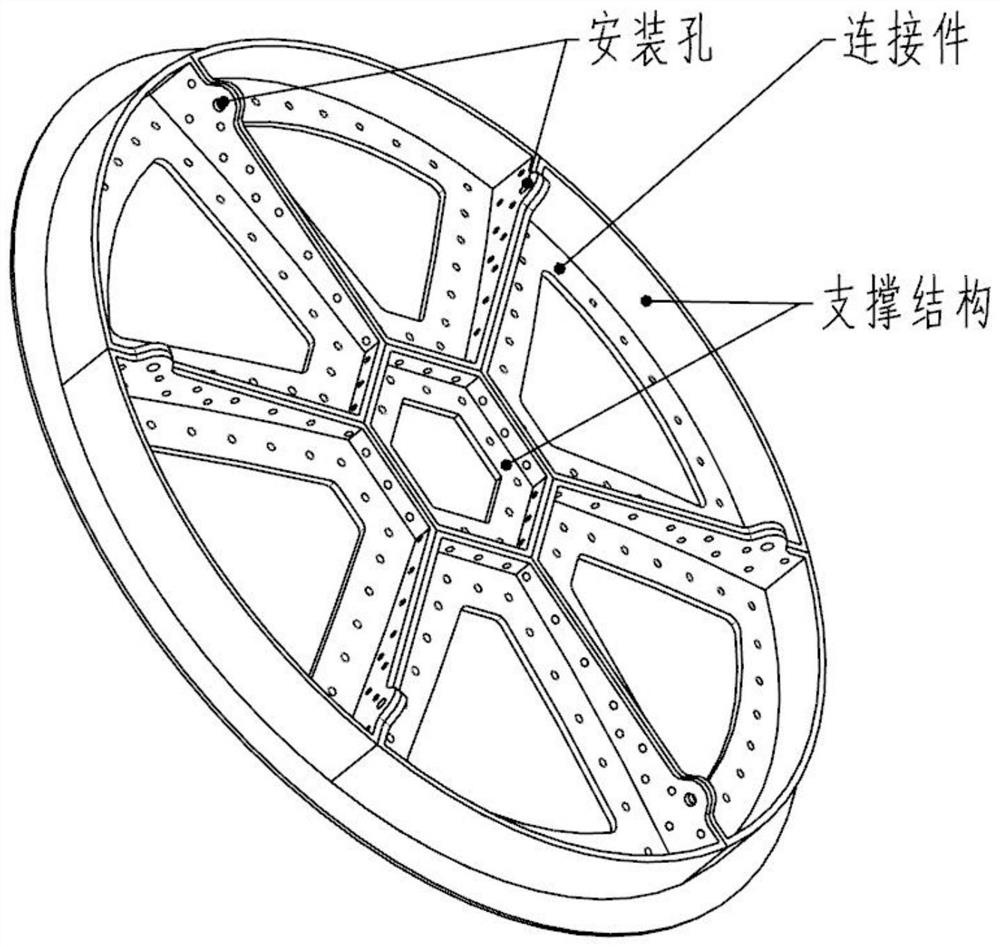

[0057] The reflector structure of this embodiment includes a reflective surface, a support structure, and multiple connectors. The reflective surface, support structure, and connectors are all made of continuous carbon fiber reinforced silicon carbide ceramic matrix composites. The reflective surface and the support structure are connected by connectors and passed through In-situ homogeneous welding of the third chemical vapor deposition process;

[0058] (1) Using continuous carbon fiber, prepare the corresponding fiber prefabricated body according to the structure model of the reflective surface and the supporting structure. The volume fraction of the mirror surface of the material is 40-48%;

[0059] (2) Put the fiber prefabricated body prepared in step (1) into the graphite mold for shaping, and put the graphite mold with the fiber prefabricated body into the reacti...

Embodiment 3

[0069] A method for preparing a silicon carbide ceramic matrix composite mirror, comprising the steps of:

[0070] The reflector structure of this embodiment includes a reflective surface, a support structure, and multiple connectors. The reflective surface, support structure, and connectors are all made of continuous silicon carbide fiber-reinforced silicon carbide ceramic matrix composites, and the reflective surface and the support structure are connected by connectors. And through the third chemical vapor deposition process in situ homogeneous welding as a whole;

[0071] (1) Continuous silicon carbide fibers are used to prepare corresponding fiber prefabricated bodies according to the structural model of the reflective surface and supporting structure. The fiber prefabricated bodies are stitched by plain weave two-dimensional cloth laminated layers, and the continuous fibers in the fiber prefabricated body account for the silicon carbide ceramics The volume fraction of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com