AL-Ca alloy and manufacturing method thereof

An alloy and crucible technology, applied in the field of AL-Ca alloy and its manufacturing, can solve the problems of low tensile strength of AL-Ca alloy and increase the difficulty of processing, and achieve the effect of convenient cutting, preventing air leakage and ensuring work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] like figure 1 As shown, an AL-Ca alloy, the AL-Ca alloy raw material weight percentage composition is: Ca2.65%, Mg1.55%, Mn1.2%, Fe0.4%, Si0.5%, Zr0.3%, Impurities and balance are Al;

[0049] The individual impurities are less than 0.05%, and the total amount of impurities is not less than 0.15%.

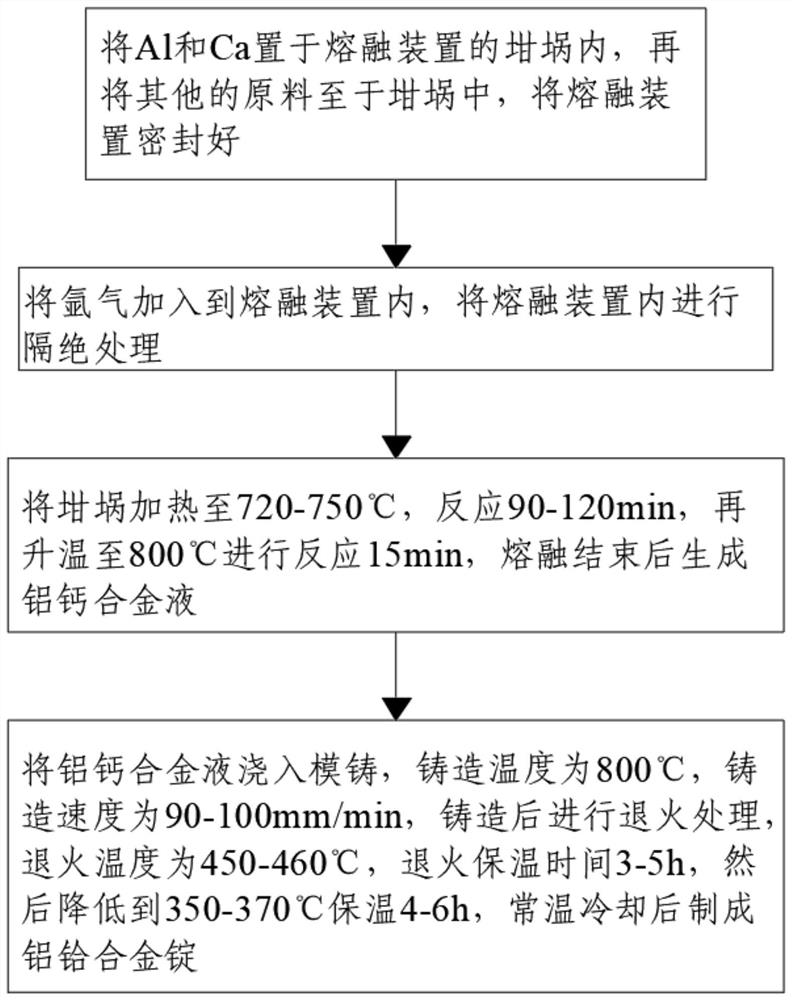

[0050] A kind of manufacture method of AL-Ca alloy, concrete steps are as follows:

[0051] S1, Al and Ca are placed in the crucible of the melting device, and other raw materials are placed in the crucible, and the melting device is sealed;

[0052] S2, adding argon gas into the melting device, and performing isolation treatment in the melting device;

[0053] S3, heating the crucible to 720°C, reacting for 120min, then warming up to 800°C and reacting for 15min, and generating an aluminum-calcium alloy liquid after melting;

[0054] S4. Pour the aluminum-calcium alloy liquid into the die casting, the casting temperature is 800°C, the casting speed is 100mm / min, and the...

Embodiment 2

[0056] Example 2 is a further improvement to Example 1.

[0057] like figure 1 As shown, an AL-Ca alloy, the AL-Ca alloy raw material weight percentage composition is: Ca2.15%, Mg2.45%, Mn0.8%, Fe0.4%, Si0.5, Zr0.3%, Impurities and balance are Al;

[0058] The individual impurities are less than 0.05%, and the total amount of impurities is not less than 0.15%.

[0059] A kind of manufacture method of AL-Ca alloy, concrete steps are as follows:

[0060] S1, Al and Ca are placed in the crucible of the melting device, and other raw materials are placed in the crucible, and the melting device is sealed;

[0061] S2, adding argon gas into the melting device, and performing isolation treatment in the melting device;

[0062] S3, heating the crucible to 750°C, reacting for 90min, then warming up to 800°C and reacting for 15min, and generating an aluminum-calcium alloy liquid after melting;

[0063] S4. Pour the aluminum-calcium alloy liquid into the die casting, the casting temp...

Embodiment 3

[0066] Example 3 is a further improvement to Example 1.

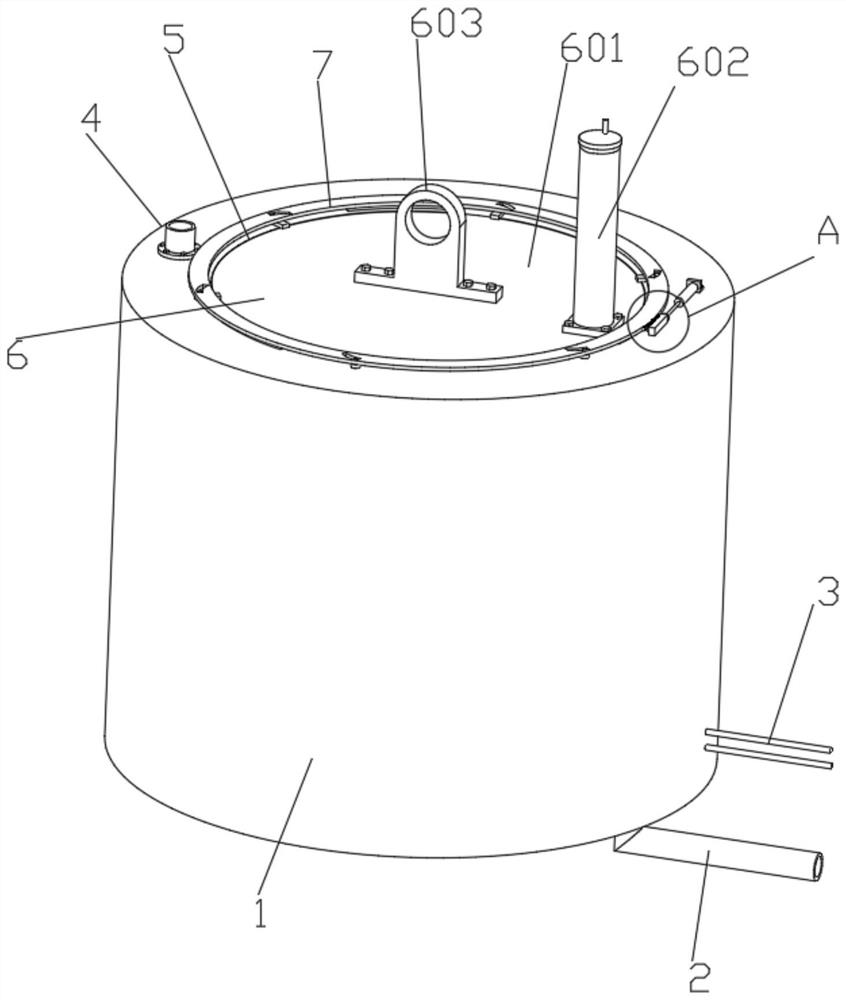

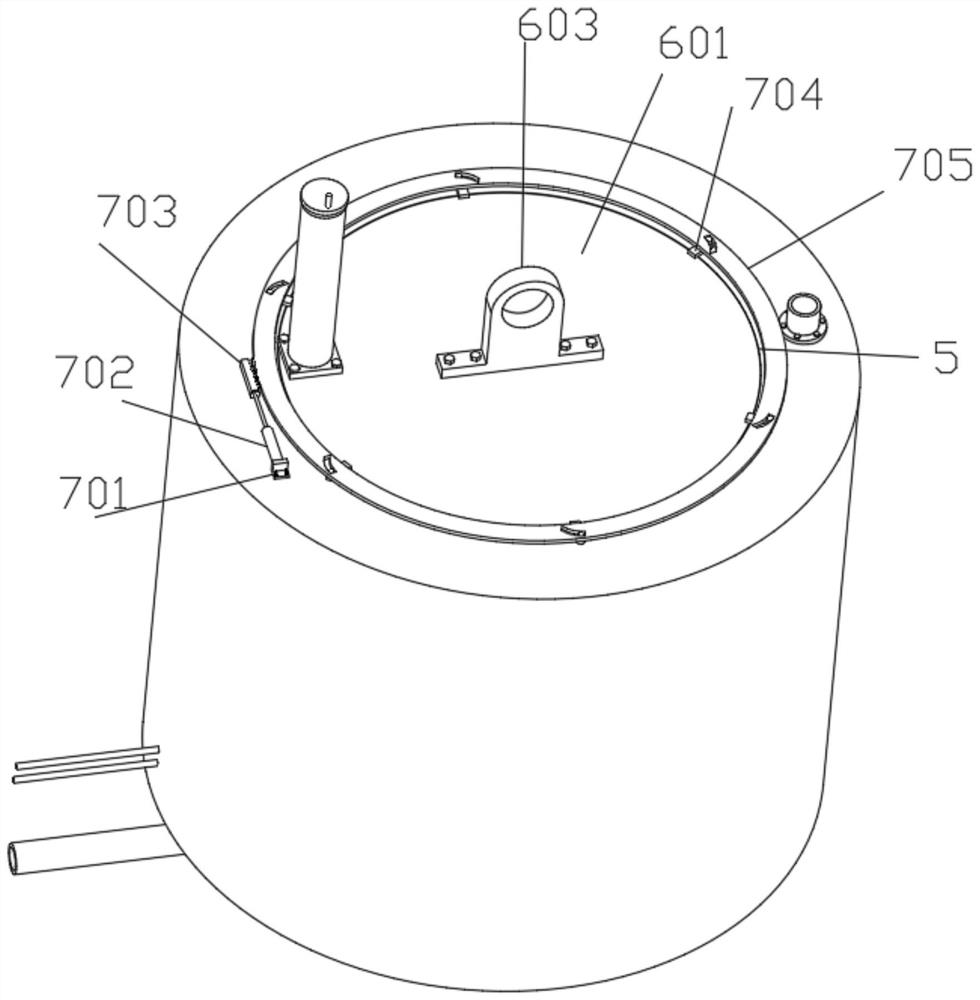

[0067] like figure 2 , 3 , 4, 5, 6, 11, an AL-Ca alloy device, the device is a melting device, including the straight hole of the furnace body 1 is fixedly connected with an intake pipe 2 for adding argon, and the intake pipe 2 passes through the air pump. Connect with argon source;

[0068] The inner bottom of the furnace body 1 is fixedly installed with an installation cylinder 10, the inner wall of the installation cylinder 10 is fixedly installed with an induction coil 9 for heating, and both ends of the induction coil 9 are fixedly connected with a connection cable 3, and the connection cable 3 is connected with the external power box. ;

[0069] A gas outlet pipe 4 is fixedly connected to the top straight hole of the furnace body 1, and the gas outlet pipe 4 is connected with the waste gas collection box;

[0070] The top middle end of the furnace body 1 is provided with a groove 5, and the groove 5 is connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com