Super-soft bi-component waterproof and breathable non-woven fabric and production process thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

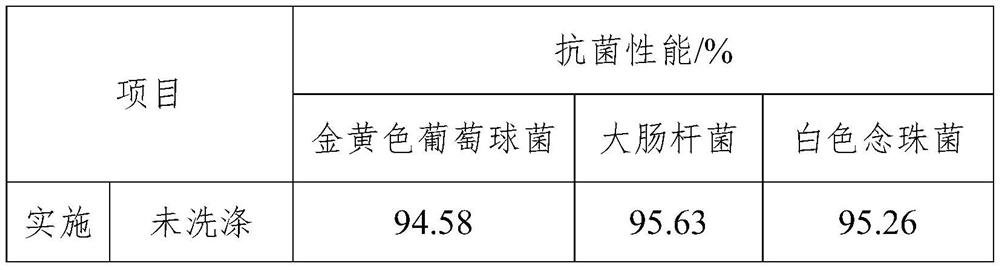

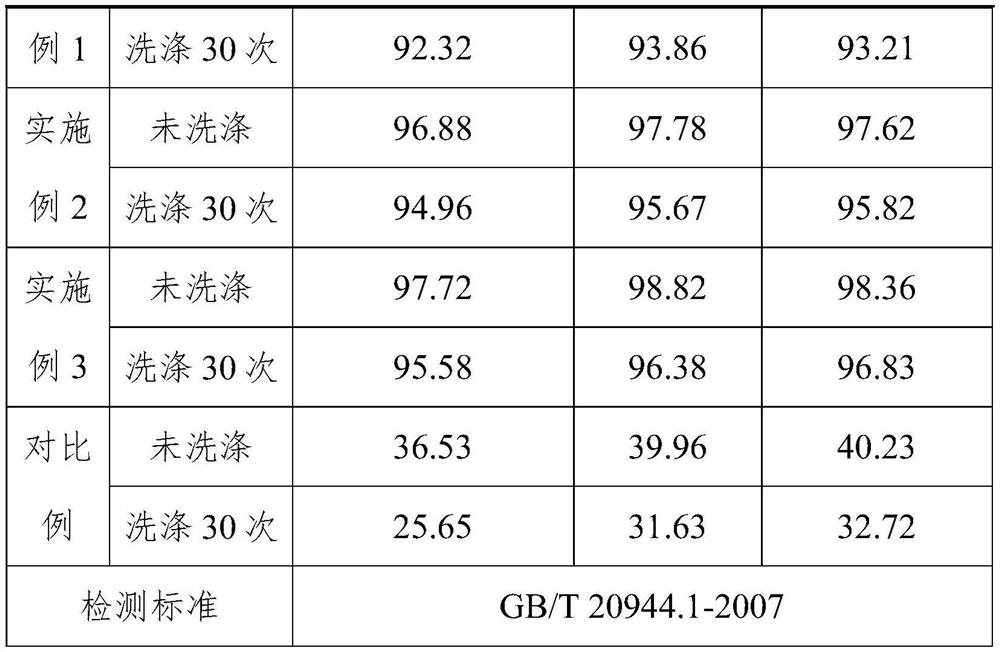

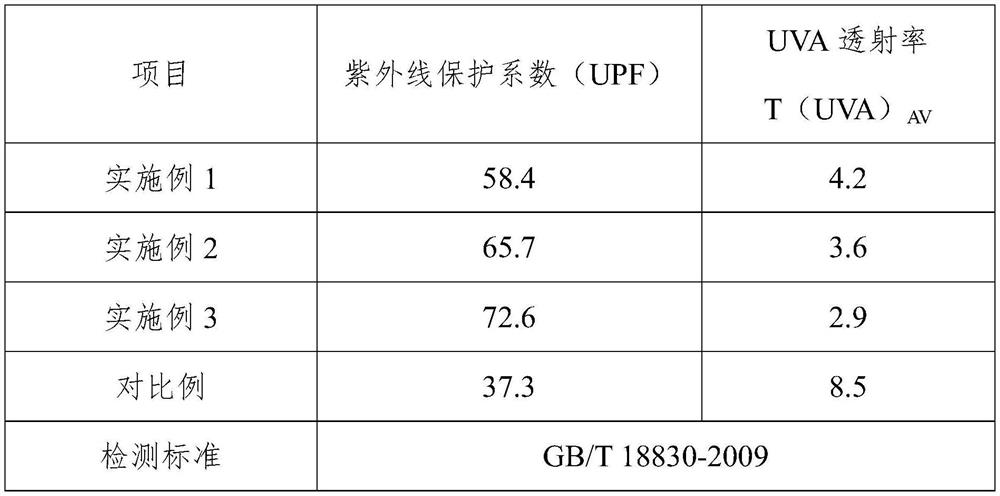

Embodiment 1

[0031] To achieve the above object, the present invention provides the following technical solutions:

[0032] An ultra-soft two-component waterproof and breathable non-woven fabric, including two layers of PE spunbond non-woven fabric layers with soft and breathable functions on the outer layer and modified PP melt-blown non-woven fabric layers on the inner layer .

[0033] Further, the modification treatment process of the PP nonwoven layer comprises the following steps:

[0034] Ⅰ. Immerse the inner PP melt-blown layer as a non-woven fabric product in the mixed solution; raise the temperature of the mixed solution to 50°C, and ultrasonically disperse at this temperature for 20 minutes; after the ultrasonic dispersion is uniform, store it for later use;

[0035]Ⅱ. Mix the pretreated mixed solution, PP non-woven fabric, modifier with a mass of 30% of PP non-woven fabric, dicyclopentenyl acrylate DCPA with a mass of 5% of PP non-woven fabric, and modified The initiator of 0....

Embodiment 2

[0048] An ultra-soft two-component waterproof and breathable non-woven fabric, including two layers of PE spunbond non-woven fabric layers with soft and breathable functions on the outer layer and modified PP melt-blown non-woven fabric layers on the inner layer .

[0049] The modification treatment process of described PP non-woven fabric layer comprises the following steps:

[0050] 1. Immerse the inner PP melt-blown layer as a non-woven fabric product in the mixed solution; raise the temperature of the mixed solution to 60°C, and disperse ultrasonically at this temperature for 25 minutes; after the ultrasonic dispersion is uniform, store it for later use;

[0051] Ⅱ. Mix the pretreated mixed solution, PP non-woven fabric, modifier with a mass of 35% of PP non-woven fabric, dicyclopentenyl acrylate DCPA with a mass of 7.5% of PP non-woven fabric, and a mass of modified The initiator of 0.7% of the agent is added in the reactor successively, and nitrogen is injected into the...

Embodiment 3

[0064] An ultra-soft two-component waterproof and breathable non-woven fabric, including two layers of PE spunbond non-woven fabric layers with soft and breathable functions on the outer layer and modified PP melt-blown non-woven fabric layers on the inner layer .

[0065] The modification treatment process of described PP non-woven fabric layer comprises the following steps:

[0066] Ⅰ. Immerse the inner PP melt-blown layer as a non-woven fabric product in the mixed solution; raise the temperature of the mixed solution to 65°C, and ultrasonically disperse at this temperature for 30 minutes; after the ultrasonic dispersion is uniform, store it for later use;

[0067] Ⅱ. Mix the pretreated mixed solution, PP non-woven fabric, modifier with a mass of 40% of PP non-woven fabric, dicyclopentenyl acrylate DCPA with a mass of 10% of PP non-woven fabric, and modified Add 0.8% of the initiator in the reactor successively, inject nitrogen into the reactor, replace the air in the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com