Organic gold conductor paste

A gold conductor and organic carrier technology, which is applied in the field of organic gold conductor paste to achieve the effects of reducing square resistance, improving adhesion and scratch resistance, and compacting and flattening roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

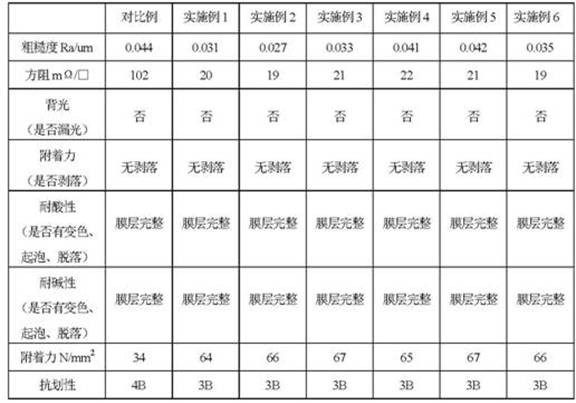

Examples

preparation example Construction

[0015] Preparation of organic vehicle: Mix 80g terpineol and 20g epoxy resin NPEL-127 together, heat in a water bath to 80°C, stir continuously until the solution is completely dissolved and in a uniform state, then stop heating; cool at room temperature for 24 hours and store for use.

[0016] Synthesis of gold resinate: dissolve gold trichloride with an acidity of 8% in isopropanol to obtain a solution with a gold trichloride content (weight ratio) of 30%, and pour the above solution into a 10% sulfur Sulfurized balsam, made a solution with a molar ratio of gold and sulfur of 1:0.1, stirred and reacted the solution at a temperature of 80°C for 8 hours, washed and precipitated crystals with isopropanol after the reaction, reduced pressure to 0.8 atmospheres, distilled and dried 1.5 Hours, the dark brown paste-like vulcanized balsam gold compound, namely gold resinate, is finally obtained, which is stored for later use.

Embodiment 1

[0020] Get 40g of gold resinate, 1g of lead octoate, 2g of bismuth 2-hexyl hexane, 0.1g of rhodium octoate, 2g of silicon 2-ethylhexanoate, 1g of vanadium isooctanoate, 2g of trimethyl boron, 50.9g of organic carrier, oily gold Nano-solution (diameter 5nm) 1g, stirred by high-speed disperser, fully dispersed by three rollers, vacuum defoaming, to obtain organic gold conductor slurry.

Embodiment 2

[0022] Get 40g of gold resinate, 1g of lead octoate, 2g of bismuth 2-hexyl hexane, 0.1g of rhodium octoate, 2g of silicon 2-ethylhexanoate, 1g of vanadium isooctanoate, 2g of trimethyl boron, 49.4g of organic carrier, oily gold 2.5g of nanometer solution (diameter 5nm) was stirred by a high-speed disperser, fully dispersed by three rollers, and vacuum defoamed to obtain an organic gold conductor slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com