HZO/AO/HZO nano laminated film and preparation method and application thereof

A nano-laminate and thin-film technology, applied in nanotechnology, nanotechnology, semiconductor/solid-state device manufacturing, etc., can solve the problems of reduced remanent polarization, reduced storage window, device failure, etc., to reduce leakage current density, The effect of improving the breakdown electric field and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

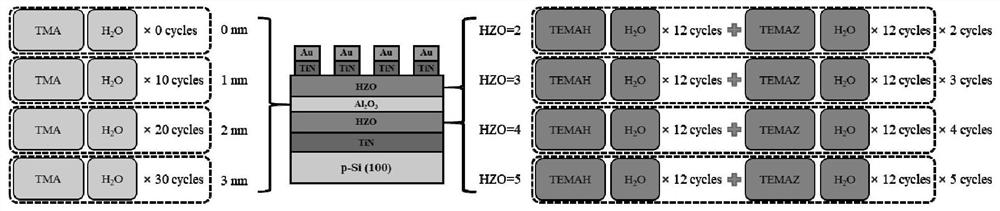

[0043] Firstly, a 60nm TiN layer is deposited on the surface of the cleaned Si sheet by magnetron sputtering technology. Then deposited on TiN (HfO 2 / ZrO 2 ) n / Al 2 o 3 / (HfO 2 / ZrO 2 ) n film:

[0044] (1) Place the substrate in the reaction chamber, place it in the ALD deposition chamber, evacuate to 10hPa, and inject N into each pipeline. 2As a protective gas, set the flow rate of the carrier gas in the pipeline to 120 sccm, the temperature of the deposition chamber to 250°C, and feed gaseous tetrakis-(methylethylamino) hafnium into the reaction chamber, the flow rate of the carrier gas to 120 sccm, and the pulse time to 1.6s ; with high purity N 2 Purge to remove excess hafnium precursor; gaseous water is introduced into the reaction chamber, the carrier gas flow rate is 150sccm, the pulse time is 0.1s, and the thermal reaction is used to generate HfO 2 thin film; with high-purity N 2 Sweep off excess water and by-products; repeat the cycle of Hf source and wa...

Embodiment 2

[0050] Firstly, a 60nm TiN layer is deposited on the surface of the cleaned Si sheet by magnetron sputtering technology. Then deposited on TiN (HfO 2 / ZrO 2 ) n / Al 2 o 3 / (HfO 2 / ZrO 2 ) n film:

[0051] (1) Place the substrate in the reaction chamber, place it in the ALD deposition chamber, evacuate to 10hPa, and inject N into each pipeline. 2 As a protective gas, set the flow rate of the carrier gas in the pipeline to 120 sccm, the temperature of the deposition chamber to 250°C, and feed gaseous tetrakis-(methylethylamino) hafnium into the reaction chamber, the flow rate of the carrier gas to 120 sccm, and the pulse time to 1.6s ; with high purity N 2 Purge to remove excess hafnium precursor; gaseous water is introduced into the reaction chamber, the carrier gas flow rate is 150sccm, the pulse time is 0.1s, and the thermal reaction is used to generate HfO 2 thin film; with high-purity N 2 Sweep off excess water and by-products; repeat the cycle of Hf source and w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com