Underground coal mine universal type self-power-generating device

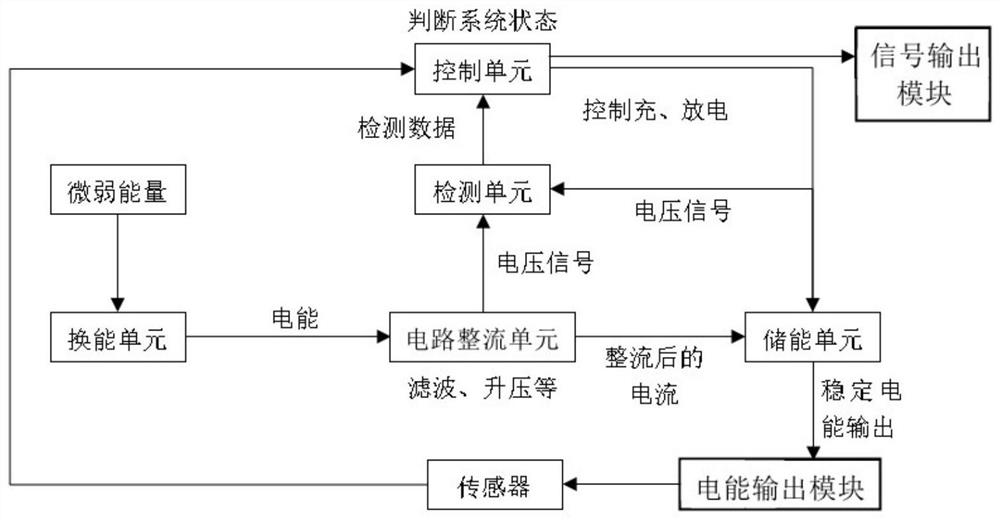

A general-purpose, self-generating technology, applied in the field of electronic information, can solve problems such as difficult maintenance in the later period, potential safety hazards, and a large number of cables, and achieve the effect of reducing damage to sensors, improving convenience, and strong scalability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

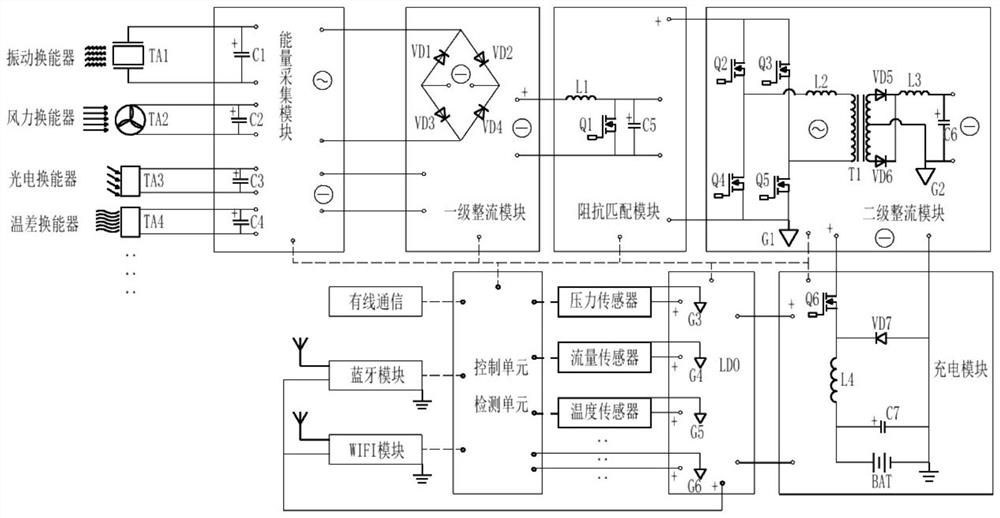

[0059] Embodiment 1: A vibration self-generating device composed of a piezoelectric crystal oscillator.

[0060] When the mechanical equipment is working, the magnetic seat of the self-generating device is adsorbed on the surface of the vibrating equipment (not limited to motors, mud pumps, drilling rig fuselages, etc.). The mechanical energy transducing unit receives the vibration energy and converts the mechanical energy into alternating current through the piezoelectric sensor. Since it is an AC transducer, the electric energy passes through the first diode VD1, the second diode VD2, and the first diode VD2 in the primary rectification module. A full-bridge AC / DC circuit composed of three diodes VD3 and a fourth diode VD4 is converted into direct current. After passing through the impedance matching circuit, it flows into the secondary rectification circuit, passes through the second MOS transistor Q2, the third MOS transistor Q3, and the fourth MOS transistor Q4 to form a ...

Embodiment 2

[0061] Embodiment 2: A temperature difference self-generating device connected with a temperature difference energy collector.

[0062] When the equipment is working, the temperature of the hydraulic oil rises due to being compressed, and the magnetic seat of the self-generating device is adsorbed on the surface of the radiator. The energy conversion unit receives the high temperature on the surface of the radiator and the low temperature in the environment to form a temperature gradient, thereby generating an electromotive force. Because it is a DC transducer, the electric energy directly flows into the impedance matching module through the first-stage rectification module. After passing through the impedance matching circuit, it flows into the secondary rectification circuit, passes through the second MOS transistor Q2, the third MOS transistor Q3, and the fourth MOS transistor Q4 to form a DC / AC circuit, passes through the second inductor L2, and the transformer T1 performs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com