Comprehensive energy utilization method for polycrystalline silicon tail gas

A technology of polysilicon and exhaust gas, applied in the direction of separation methods, silicon compounds, silicon halide compounds, etc., to achieve the effects of saving energy, increasing processing capacity, and controlling energy consumption of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

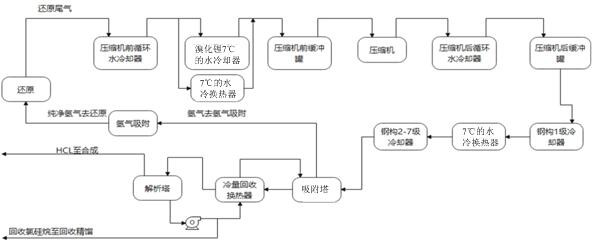

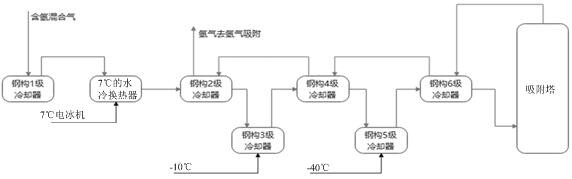

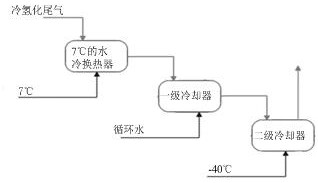

[0031] This embodiment is a comprehensive energy utilization method for polysilicon tail gas. This method is mainly aimed at the increase in the amount of reduction tail gas after the existing reduction capacity is increased, and the recovery system and cold hydrogenation system for the reduction tail gas will be used in the future due to the increase in energy consumption. The problem that the processing capacity cannot be further improved. Solutions include: adding a 7°C water-cooled heat exchanger in the reduction tail gas recovery steel structure system, and adding a 7°C water-cooled heat exchanger in the cold hydrogenation tail gas condensation system.

[0032] First of all, the reduction tail gas recovery steel structure system is to reduce the chlorosilane (trichlorosilane, silicon tetrachloride, dichlorodihydrosilane), H 2 and HCl to separate the process system, the chlorosilane is sent to the recovery rectification unit, the H 2 After being sent to the adsorption uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com