Modified nanocellulose/polypyrrole composite material and preparation method thereof, and antistatic rubber composition and preparation method thereof

A technology of nanocellulose and rubber composition, which is applied in the field of tire rubber formulation, can solve the problems affecting the compatibility and dispersion of non-polar rubber, poor compatibility, poor hydrophobicity, etc., to increase the binding effect and improve the electrical conductivity , Improve the effect of antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

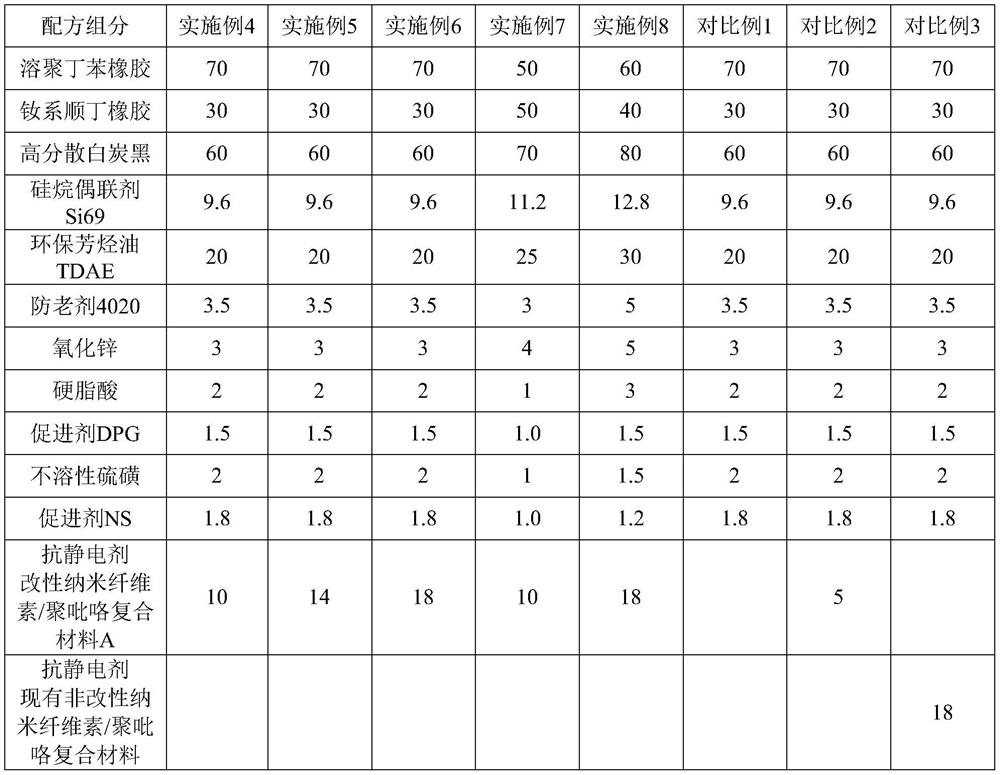

Examples

Embodiment 1

[0044] A preparation method of modified nanocellulose / polypyrrole composite material A, specifically comprising the following steps:

[0045] S1. Preparation of modified nanocellulose: 100 parts by weight of nanocellulose is formulated into a 2 g / L aqueous solution of nanocellulose, and the aqueous solution of nanocellulose, 0.5 parts by weight of initiator and 20 parts by weight of styrene are placed in a flask , stirred at 70°C for 17 minutes, added dropwise 40 parts by weight of acrylic acid, and reacted at the reaction temperature for 120 minutes to obtain a modified nanocellulose suspension;

[0046] S2. Add 60 parts by weight of pyrrole and 22 parts by weight of toluene-4-sulfonic acid into the modified nanocellulose suspension, stir magnetically for 1.5 hours in an ice-water bath, and add 19 parts by weight of 0.1mol / L FeCl dropwise 3 , reacted for 9 hours under ice-water bath conditions, and obtained modified nanocellulose / polypyrrole composite material A after suction...

Embodiment 2

[0048] A preparation method of modified nanocellulose / polypyrrole composite material B, specifically comprising the following steps:

[0049] S1. Preparation of modified nanocellulose: 90 parts by weight of nanocellulose are formulated into a 2 g / L aqueous solution of nanocellulose, and the aqueous solution of nanocellulose, 0.4 parts by weight of initiator and 15 parts by weight of styrene are placed in a flask , stirred at 60°C for 15 minutes, added dropwise 30 parts by weight of acrylic acid, and reacted at the reaction temperature for 60 minutes to obtain a modified nanocellulose suspension;

[0050] S2. Add 50 parts by weight of pyrrole and 15 parts by weight of toluene-4-sulfonic acid into the modified nanocellulose suspension, stir magnetically for 1 h under ice-water bath conditions, and add 17 parts by weight of 0.1mol / L FeCl dropwise 3 , reacted for 8 hours under ice-water bath conditions, and obtained modified nanocellulose / polypyrrole composite material B after suc...

Embodiment 3

[0052] A preparation method of modified nanocellulose / polypyrrole composite material C, specifically comprising the following steps:

[0053] S1. Preparation of modified nanocellulose: 110 parts by weight of nanocellulose are formulated into a 2g / L aqueous solution of nanocellulose, and the aqueous solution of nanocellulose, 0.6 parts by weight of initiator and 25 parts by weight of styrene are placed in a flask , stirred at 85°C for 20 minutes, added dropwise 50 parts by weight of acrylic acid, and reacted at the reaction temperature for 180 minutes to obtain a modified nanocellulose suspension;

[0054] S2. Add 70 parts by weight of pyrrole and 25 parts by weight of toluene-4-sulfonic acid into the modified nanocellulose suspension, stir magnetically for 2 hours in an ice-water bath, and add 22 parts by weight of 0.1mol / L FeCl dropwise 3 , reacted for 10 hours under ice-water bath conditions, and obtained modified nanocellulose / polypyrrole composite material C after suction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com