Preparation method and preparation system of mesophase pitch

A technology for mesophase pitch and preparation system, which is applied in the field of mesophase pitch preparation, can solve the problems affecting the spinnable carbon fiber performance of mesophase pitch, low production efficiency and high corrosiveness, so as to prevent the viscosity of the system from increasing too fast and decreasing content and the effect of improving the viscosity of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

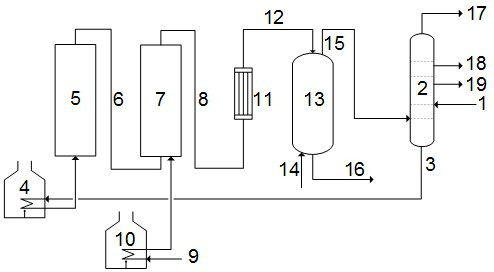

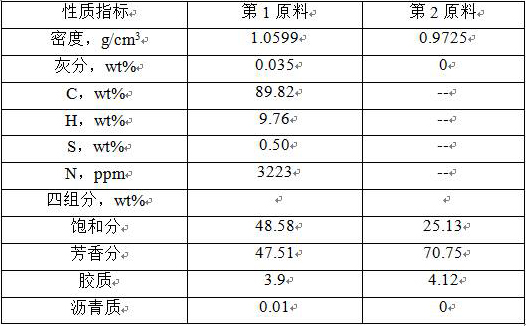

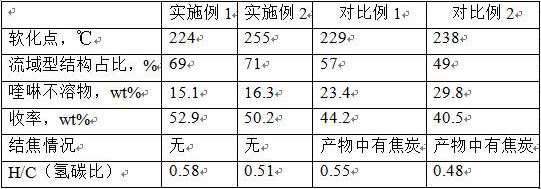

[0060] Embodiment 1 adopts figure 1 In the production system shown, the cooling rate of the quenching device is 150°C / S, the properties of raw materials are shown in Table 1, the operating conditions are shown in Table 2, and the reaction results are shown in Table 3.

Embodiment 2

[0062] Compared with Example 1, the operating conditions are slightly different. The cooling rate of the quenching device is 180° C. / S. The properties of the raw materials are shown in Table 1, the operating conditions are shown in Table 2, and the reaction results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com