Method for modifying carbon fibers for paper-based friction material

A paper-based friction material and carbon fiber technology, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., to achieve high surface activity, good dispersibility, and the effect of improving material strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

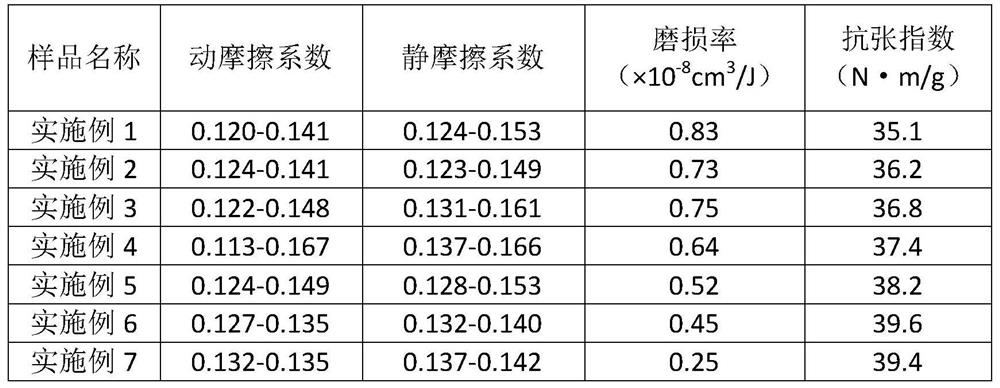

Examples

Embodiment 1

[0025] Embodiment 1: A method for modifying carbon fibers for paper-based friction materials, comprising the following steps:

[0026] (1) Preparation of carbon fiber pretreatment system

[0027] Sodium dodecylbenzenesulfonate is dispersed at a concentration of 0.01 wt% to obtain a carbon fiber pretreatment liquid.

[0028] (2) Pretreatment process of carbon fiber

[0029] The carbon fiber pretreatment concentration is 2wt%, the stirring speed is 60 rpm, and the pretreatment time is 30 minutes.

[0030] (3) Preparation of carbon fiber layer assembly deposition modification system

[0031] Cationic polyacrylamide and cationic starch are selected, and anionic polymers include anionic polyacrylamide.

[0032] (4) Carbon fiber layer assembly deposition modification process

[0033] The concentration of the cationic deposition modifier system is 0.2 wt%, the stirring speed is 30 rpm, and the deposition modification time is 10 min. The concentration of the anion deposition modi...

Embodiment 2

[0036] Embodiment 2: A method for modifying carbon fibers for paper-based friction materials, comprising the following steps:

[0037] (1) Preparation of carbon fiber pretreatment system

[0038] The stearic acid is dispersed according to the concentration of 0.02wt% to obtain the carbon fiber pretreatment liquid.

[0039] (2) Pretreatment process of carbon fiber

[0040] The carbon fiber pretreatment concentration is 3wt%, the stirring speed is 70 rpm, and the pretreatment time is 40min.

[0041] (3) Preparation of carbon fiber layer assembly deposition modification system

[0042] Cationic starch is selected as the cationic modified polymer; anionic water-based polyurethane is selected as the anionic modifier.

[0043] (4) Carbon fiber layer assembly deposition modification process

[0044] The concentration of the cationic deposition modifier system is 0.3 wt%, the stirring speed is 40 rpm, and the deposition modification time is 12 min. The concentration of the anion ...

Embodiment 3

[0047] Embodiment 3: A method for modifying carbon fibers for paper-based friction materials, comprising the following steps:

[0048] (1) Preparation of carbon fiber pretreatment system

[0049] The stearic acid is dispersed according to the concentration of 0.03wt% to obtain the carbon fiber pretreatment liquid.

[0050] (2) Pretreatment process of carbon fiber

[0051] The carbon fiber pretreatment concentration is 4wt%, the stirring speed is 80 rpm, and the pretreatment time is 50min.

[0052] (3) Preparation of carbon fiber layer assembly deposition modification system

[0053] Cationic guar gum is selected as the cationic modified polymer; styrene-acrylic emulsion is selected as the anionic modifier.

[0054] (4) Carbon fiber layer assembly deposition modification process

[0055] The concentration of the cationic deposition modifier system is 0.4 wt%, the stirring speed is 50 rpm, and the deposition modification time is 13 min. The concentration of the anion depositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com