Composite organic silicon coating as well as preparation method and application thereof

A technology of organosilicon coating and hydroxy silicone oil, applied in anti-corrosion coatings, coatings, etc., can solve the problem that the corrosion resistance needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

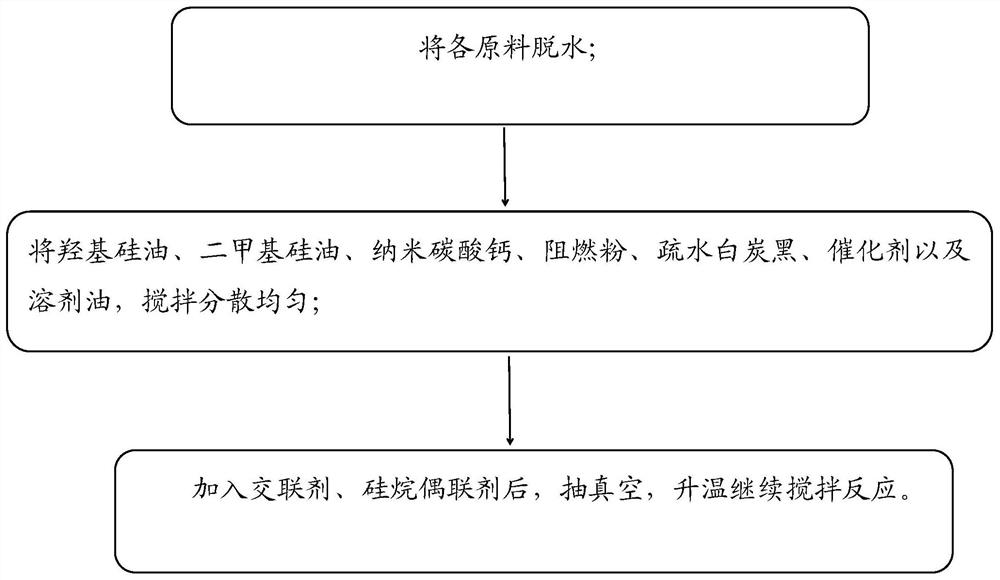

[0052] The present embodiment 1 provides the preparation method of the first kind of composite organosilicon coating, comprises the steps:

[0053] Step 1: dehydrating each raw material to a water content below 0.3wt%;

[0054] Step 2: Put 30g of hydroxyl silicone oil, 6g of dimethyl silicone oil, 1g of nano-calcium carbonate, 2.5g of terminal hydrogen-containing silicone oil, 10g of flame retardant powder, 3g of hydrophobic white carbon black, 0.03g of catalyst, and 100g of No. 120 solvent oil into the planetary bucket. Stir and disperse evenly;

[0055] Step 3: Add 2g of crosslinking agent and 1g of silane coupling agent, vacuumize, and raise the temperature to 50-60°C; continue stirring for 1.5h to complete the reaction.

[0056] Wherein, the hydroxy silicone oil is composed of 1000cps, a low viscosity hydroxy silicone oil with a hydroxyl content of 0.2% and a 20000cps dihydroxy-terminated hydroxy silicone oil, and the weight ratio of the low-viscosity hydroxy silicone oil...

Embodiment 2

[0058] The present embodiment 2 provides the preparation method of the second kind of composite organosilicon coating, comprises the steps:

[0059] Step 1: dehydrating each raw material to a water content below 0.3wt%;

[0060] Step 2: Put 20g of hydroxyl silicone oil, 8g of dimethyl silicone oil, 2g of nano-calcium carbonate, 2g of terminal hydrogen-containing silicone oil, 15g of flame retardant powder, 1g of hydrophobic white carbon black, 0.03g of catalyst, 100g of No. 120 solvent oil into the planetary barrel, and stir Evenly dispersed;

[0061] Step 3: Add 1g of crosslinking agent and 1g of silane coupling agent, vacuumize, and raise the temperature to 50-60°C; continue stirring for 1.5h to complete the reaction.

[0062] Wherein, the hydroxy silicone oil is composed of 1500cps, low viscosity hydroxy silicone oil with a hydroxyl content of 0.15% and 20000cps of dihydroxy-terminated hydroxy silicone oil, and the weight ratio of the low-viscosity hydroxy silicone oil and...

Embodiment 3

[0064] Present embodiment 3 provides the preparation method of the 3rd kind of composite organosilicon coating, comprises the steps:

[0065] Step 1: dehydrating each raw material to a water content below 0.3wt%;

[0066] Step 2: Put 40g of hydroxyl silicone oil, 5g of dimethyl silicone oil, 0.5g of nano-calcium carbonate, 3g of terminal hydrogen-containing silicone oil, 5g of flame retardant powder, 5g of hydrophobic white carbon black, 0.05g of catalyst, and 100g of No. 120 solvent oil into the planetary bucket. Stir and disperse evenly;

[0067] Step 3: Add 3g of crosslinking agent and 2g of silane coupling agent, vacuumize, and raise the temperature to 50-60°C; continue stirring for 2h to complete the reaction.

[0068] Wherein, the hydroxy silicone oil is composed of 1500cps, a low viscosity hydroxy silicone oil with a hydroxyl content of 0.15% and a 30000cps dihydroxy-terminated hydroxy silicone oil, and the weight ratio of the low-viscosity hydroxy silicone oil and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com