Preparation method of improved wheat protein adhesive

A technology of wheat protein and production method, which is applied in the field of preparation of wheat protein adhesives, to achieve the effects of improving adhesion, improving bonding performance, and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

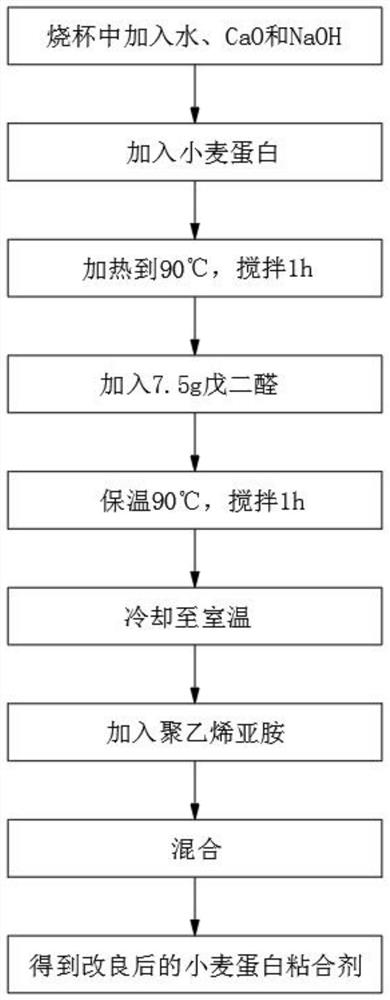

[0040] Such as figure 1 Shown: a kind of preparation method of improved wheat protein adhesive, comprises the following steps:

[0041] S1, add 55g of water, 0.1g of CaO and 0.2g of NaOH to the beaker, turn on the stirrer and mix evenly;

[0042] S2, then, slowly add the wheat protein of 18g in the beaker, adopt the mode that stirrer adds while stirring;

[0043] S3. When the mixture is heated to 85°C, keep stirring at this temperature for 1 hour;

[0044] S4. Add 7.3g of glutaraldehyde to the beaker to make the mixture fully react at 85°C. During the reaction, use a stirrer to continuously stir for 1h to increase the reactive groups of the protein adhesive such as -COOH and -OH. These functional groups Reaction with amine groups in polyethyleneimine to improve adhesion;

[0045] S5. Then the mixture is cooled to room temperature, and a certain amount of polyethyleneimine is put into the mixture for mixing to obtain an adhesive. After adding polyethyleneimine, the highly ac...

Embodiment 2

[0059] Such as figure 1 Shown: a kind of preparation method of improved wheat protein adhesive, comprises the following steps:

[0060] S1, add 60g of water, 0.2g of CaO and 0.4g of NaOH into the beaker, turn on the stirrer and mix evenly;

[0061] S2, then, slowly add the wheat protein of 20g in the beaker, adopt the mode that stirrer adds while stirring;

[0062] S3. When the mixture is heated to 90°C, keep stirring at this temperature for 1 hour;

[0063] S4. Add 7.5g of glutaraldehyde to the beaker to make the mixture fully react at 90°C. During the reaction process, use a stirrer to continuously stir for 1h to increase the reactive groups of the protein adhesive such as -COOH and -OH. These functional groups Reaction with amine groups in polyethyleneimine to improve adhesion;

[0064] S5. Then the mixture is cooled to room temperature, and a certain amount of polyethyleneimine is put into the mixture for mixing to obtain an adhesive. After adding polyethyleneimine, the...

Embodiment 3

[0078] Such as figure 1 Shown: a kind of preparation method of improved wheat protein adhesive, comprises the following steps:

[0079] S1, add 65g of water, 0.3g of CaO and 0.6g of NaOH into the beaker, turn on the stirrer and mix evenly;

[0080] S2, then, slowly add the wheat protein of 22g in the beaker, adopt the mode that stirrer adds while stirring;

[0081] S3. When the mixture is heated to 95°C, keep stirring at this temperature for 1.5h;

[0082] S4. Add 7.7g of glutaraldehyde to the beaker to make the mixture fully react at 95°C. During the reaction, use a stirrer to continuously stir for 1.5h to increase the reactive groups of the protein adhesive such as -COOH and -OH. These Functional groups react with amine groups in polyethyleneimine to improve adhesion;

[0083] S5. Then the mixture is cooled to room temperature, and a certain amount of polyethyleneimine is put into the mixture for mixing to obtain an adhesive. After adding polyethyleneimine, the highly act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com