Electrochromic cast resin laminated glass and method for the production thereof

A technology for casting resin and laminating glass, applied in synthetic resin layered products, lamination, lamination auxiliary operations, etc. The effect of improving the degree of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

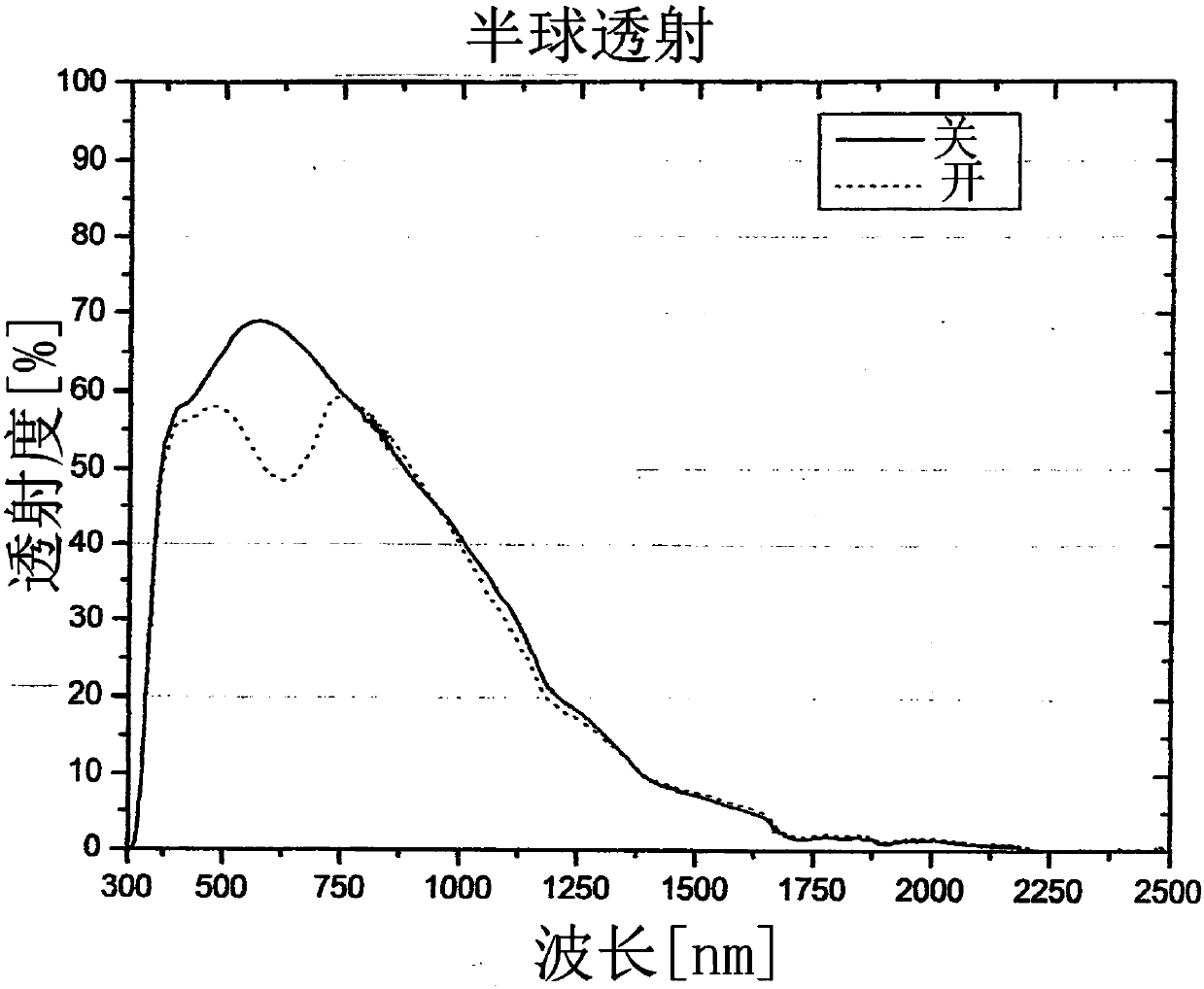

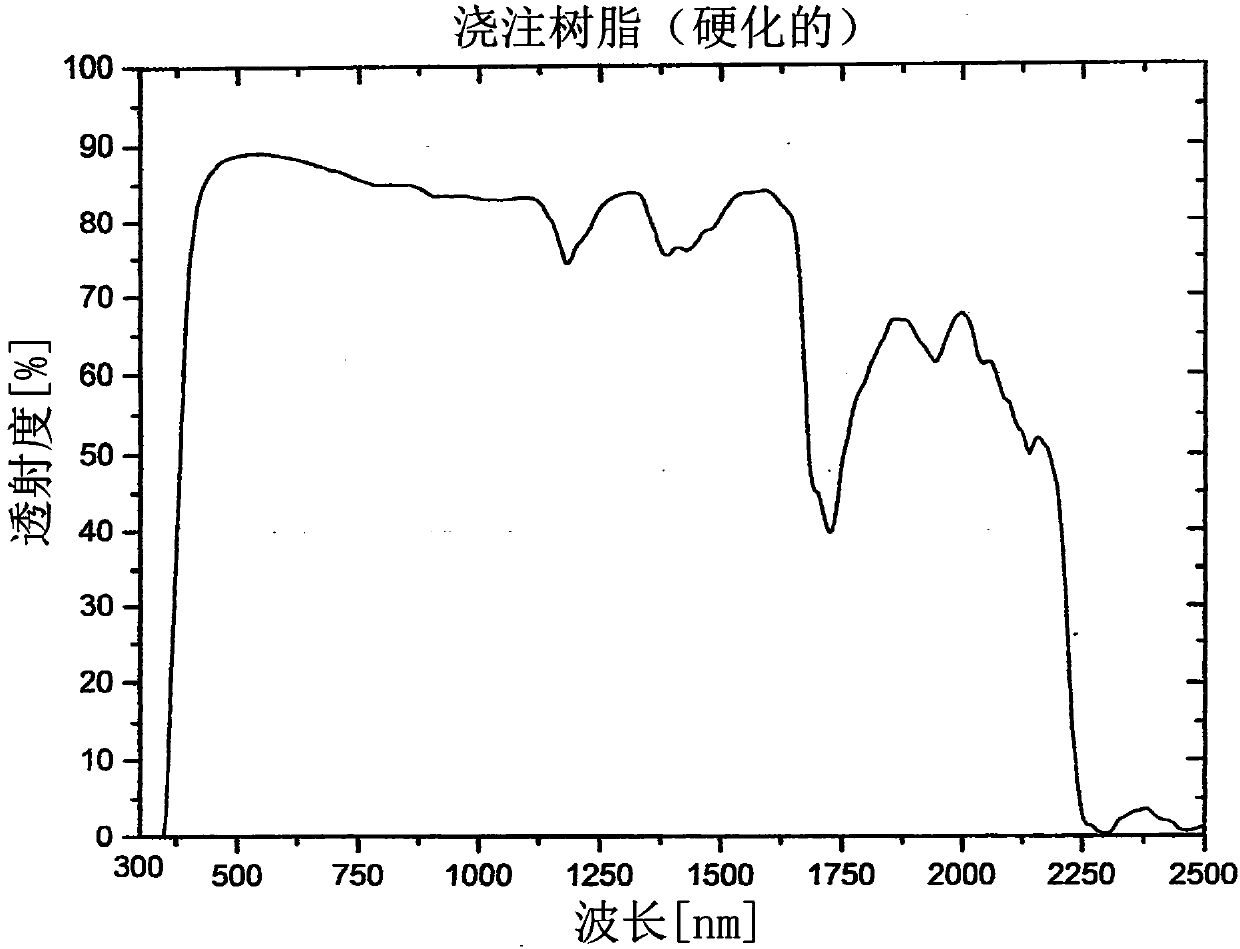

[0054] Electrochromic laminated glass was prepared by gluing two ITO-coated glasses made of 5 mm float glass, which were joined along the edges by a 1.5 mm thick acrylic adhesive tape. Prepare 72g GmbH's UV (54g 2-ethylhexyl acrylate, 9g acrylic acid, 7.3g methyl methacrylate, 1.7g tris(2-methoxyethoxy)vinylsilane), 36g propylene carbonate, 36g poly(ethylene diethylene glycol) alcohol) diacrylate (M=700g / mol), 14.4g lithium trifluoromethanesulfonate, 0.2g 2,2-dimethoxy-2-phenylacetophenone and 1.6g ethylenedioxythiophene The mixture was stirred for 30 minutes in the dark. The mixture is filled into the cavity between two 300 mm x 300 mm glass plates through a cannula or funnel, and the edges of the window are subsequently sealed with a two-component resin. Subsequently, one glass was cured for 30 minutes in a UV radiation chamber. By applying a DC voltage of 3.0 V for 1 min, a transparent polyethylenedioxythiophene film was formed on the anode, which turned blue when the...

Embodiment 2

[0056] Electrochromic laminated glass was prepared by gluing two ITO-coated glasses made of 5 mm float glass joined along the edges by a 1.5 mm thick acrylic adhesive tape. Preparation of 25.6 g methyl methacrylate, 22.4 g 1,4-butylene glycol diacrylate, 3.2 g pentaerythritol tetraacrylate, 6.4 g 2-hydroxyethyl methacrylate, 6.4 g methacrylic acid, 48 g ethylene carbonate , 48g poly(ethylene glycol) diacrylate (M=700g / mol), 16g lithium perchlorate, 18.8g 3,4-(2,2-dimethylpropylenedioxy)thiophene (ProDOT- Me 2 ) and 0.28 g of 2,2-dimethoxy-2-phenylacetophenone and stirred for 30 minutes in the dark. The mixture is filled into the cavity between two 300 mm x 300 mm glass plates through a cannula or funnel, and the edges of the window are subsequently sealed with a two-component resin. Subsequently, the glass was cured for 30 minutes in a UV radiation chamber. Transparent poly(proDOT-Me 2 ) film, which turns blue-purple when the voltage is removed. The laminate was decoloriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com