CO2 gas-sensitive material for respiratory gas detection and preparation method and application thereof

A gas-sensing material, carbon dioxide technology, applied in the field of material processing, achieves good gas-sensing performance, simple and safe preparation method, and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method and application of the gas-sensitive material of the present invention are carried out as follows:

[0036] (1) Preparation of mixed solvent: at normal temperature, 2.1g of SnCl 4 ·5H 2 O, 0.44g of Zn(AC) 2 2H 2 O, the NaOH of 1.5g, the polyvinylpyrrolidone of 1.2g, the H of 5ml mass fraction are 30% 2 o 2 The solution was mixed with an appropriate amount of deionized water, and magnetically stirred to obtain a 40ml uniformly mixed solution.

[0037] (2) Pretreatment: Transfer the mixed solution obtained in step (1) to a polytetrafluoroethylene-lined stainless steel autoclave, seal it, and react at 180°C. After the reaction, cool naturally to room temperature, centrifuge, wash, drying to obtain the precursor material;

[0038] (3) Drying treatment: place the precursor material obtained in step (2) in air at 80°C for 12 hours, then cool naturally to room temperature to obtain ZnSnO 3 Nanoparticle cluster materials.

[0039] (4) Coating: Gri...

example example 1

[0043] ZnSnO 3 Preparation of nanoparticle gas sensor:

[0044] At room temperature, 2.1g of SnCl 4 ·5H 2 O, 0.44g of Zn(AC) 2 2H 2 O, the NaOH of 1.5g, the polyvinylpyrrolidone of 1.2g, the H of 5ml mass fraction are 30% 2 o 2 The solution was mixed with an appropriate amount of deionized water, and magnetically stirred to obtain a 40ml uniformly mixed solution.

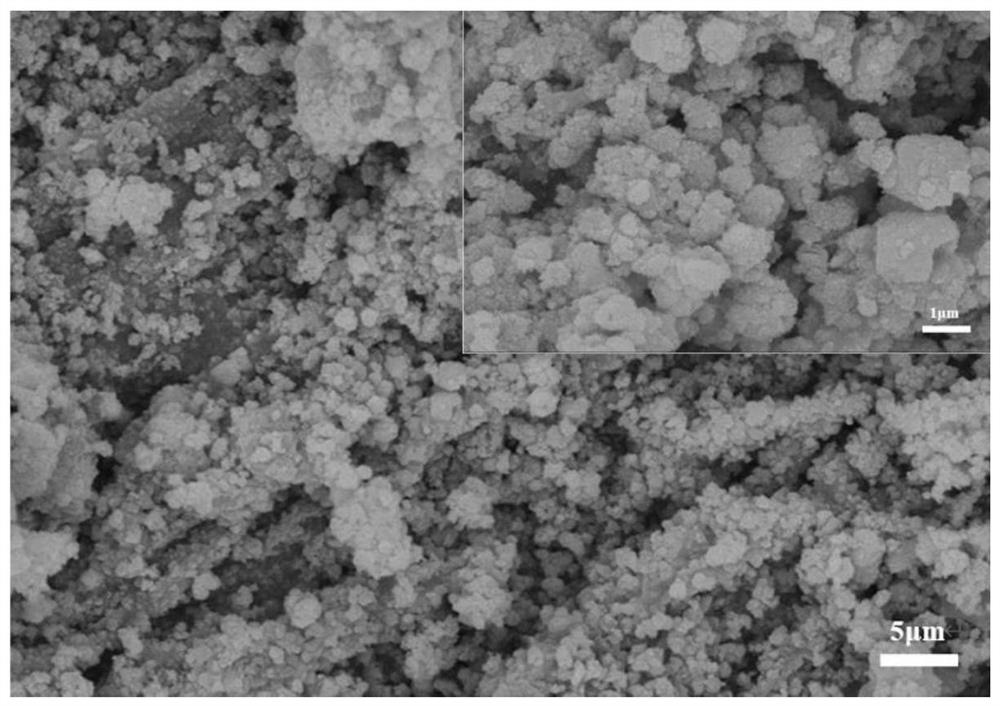

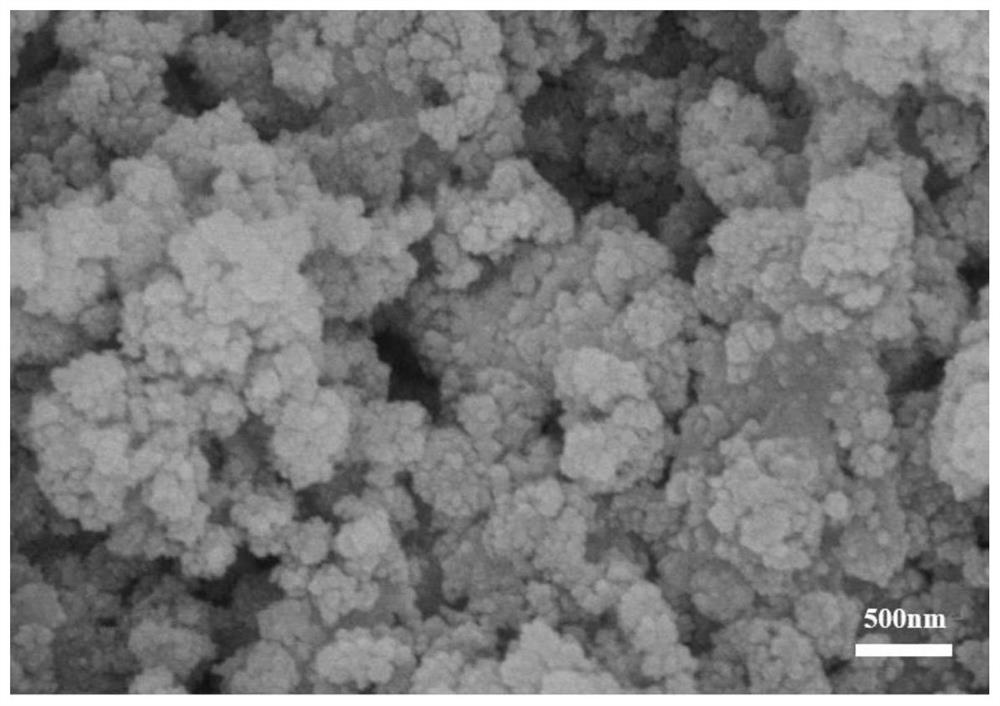

[0045] The obtained mixed solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, sealed, and reacted at 180°C for 12 hours. After the reaction was completed, it was naturally cooled to room temperature, centrifuged, washed, and dried to obtain a precursor material; The precursor material of the ZnSnO 3 Nanoparticle cluster materials.

[0046] ZnSnO 3 The nanoparticle cluster material was added to deionized water and ground to form a paste, and then the paste was evenly coated on the outer surface of the gas sensor substrate, and the gold electrode was completely covered, and ...

Embodiment 2

[0050] At room temperature, 2.1g of SnCl 4 ·5H 2 O, 0.44g of Zn(AC) 2 2H 2 The mass fraction of O, the NaOH of 1.5g, the polyvinylpyrrolidone of 1.2g, 5ml are the H of 30% 2 o 2 The solution was mixed with an appropriate amount of deionized water, and magnetically stirred for a period of time to obtain a 40ml homogeneously mixed solution, and a total of 3 parts were obtained.

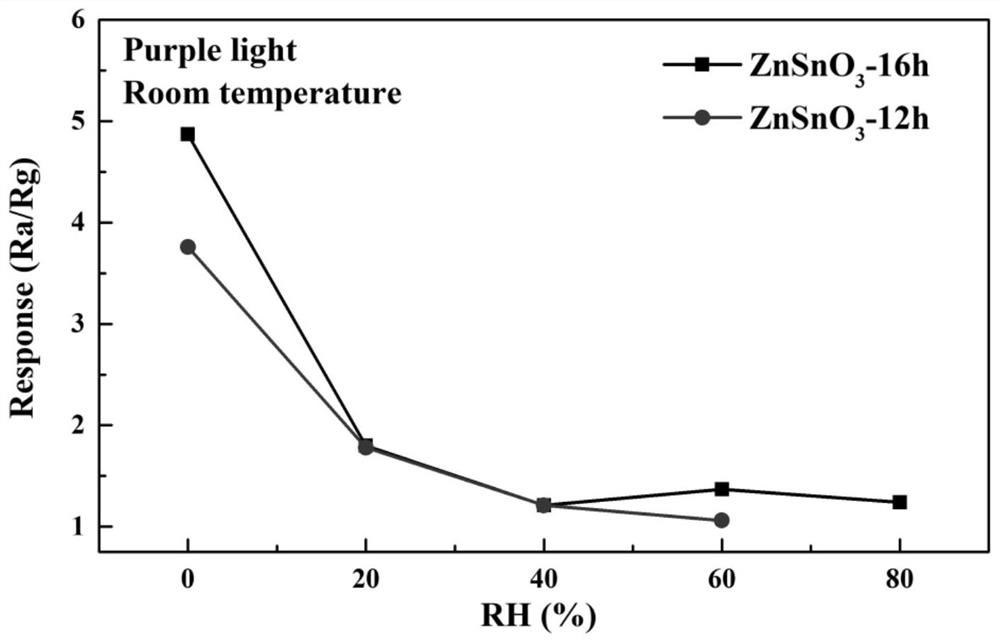

[0051] The obtained mixed solution was transferred to a polytetrafluoroethylene-lined stainless steel high-pressure reactor, sealed, and reacted at 180°C for 12h, 16h, and 20h respectively. After the reaction was completed, it was naturally cooled to room temperature, centrifuged, washed, and dried to obtain the precursor body material; the obtained precursor material was dried in air at 80°C for 12h, and then naturally cooled to room temperature to obtain ZnSnO 3 Nanoparticle cluster materials.

[0052] ZnSnO 3 The nanoparticle cluster material was added to deionized water and ground to form a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com