Integrated pole piece and preparation method thereof, secondary battery and battery module

A pole piece, polyethylene oxide technology, applied in the direction of secondary batteries, battery electrodes, battery components, etc. Solve the problems of high crystallinity of olefin separator, achieve good liquid retention capacity, thinner thickness, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] 2. A method for preparing an integrated pole piece, comprising the following steps:

[0054] Step (A): adding polyethylene oxide and polyacrylic acid into a solvent, mixing and stirring to form a complex solution;

[0055] Step (B): mixing the complex solution and ceramic powder described in step (A) to obtain a coating slurry;

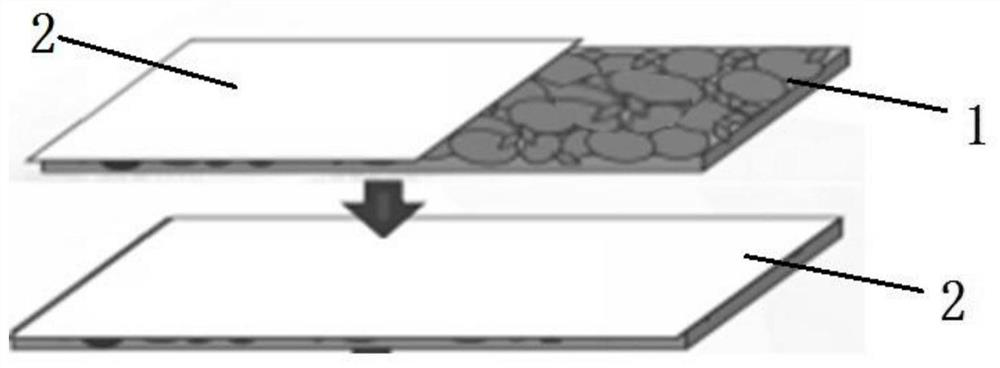

[0056] Step (C): Coating and drying the coating slurry in step (B) on at least one surface of the pole piece 1 to form a diaphragm slurry layer 2, the process is as follows figure 2 shown.

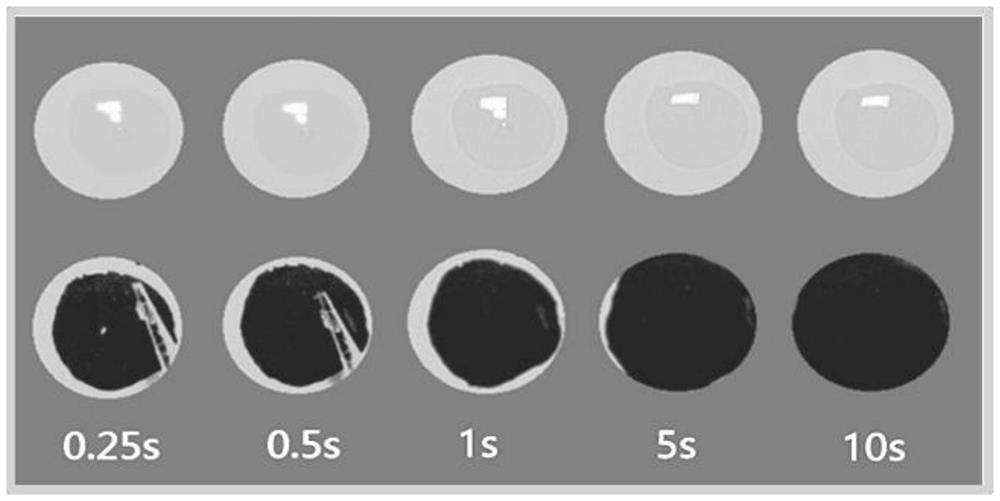

[0057] The preparation method of the integrated pole piece of the present invention has the advantages of simple preparation method, good controllability, easy operation and mass production. The prepared integrated pole piece such as Image 6 As shown, the surface is smooth without cracks, and the integrated pole piece has good flexibility. Figure 7 As shown, the surface is still smooth without cracks, which is suitable for roll core batteries and lam...

Embodiment 1

[0075] 1. A method for preparing an integrated pole piece, comprising the following steps:

[0076] Step (A): adding polyethylene oxide and polyacrylic acid into a solvent, mixing and stirring to form a complex solution;

[0077] Step (B): mixing the complex solution and wetting agent described in step (A), and then adding ceramic powder and binder and stirring and mixing to prepare a coating slurry;

[0078] Step (C): Coating and drying the coating slurry in step (B) on at least one surface of the pole piece 1 to form a diaphragm slurry layer 2, the process is as follows figure 2 As shown, the prepared integrated pole piece is as follows Image 6 with Figure 7 shown.

[0079] Wherein, the weight parts of polyethylene oxide and polyacrylic acid in the step (A) is 1:0.6.

[0080] Wherein, the molecular weight of the polyethylene oxide is 7 million.

[0081] Wherein, the parts by weight of the ceramic powder, the complex solution, the binder and the wetting agent are 84:1...

Embodiment 2

[0086] The difference from Example 1 is:

[0087] The parts by weight of polyethylene oxide and polyacrylic acid in the step (A) are 2:0.6.

[0088] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com