Vacuum filtration system of graphite heat-conducting film carbonization furnace

A technology of graphite heat-conducting film and filtration system, which is applied in chemical instruments and methods, steam condensation, and separation of dispersed particles, etc. It can solve the problems of impurity components remaining, affecting product quality, and excessive temperature difference in the furnace, etc., to improve condensation filtration. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

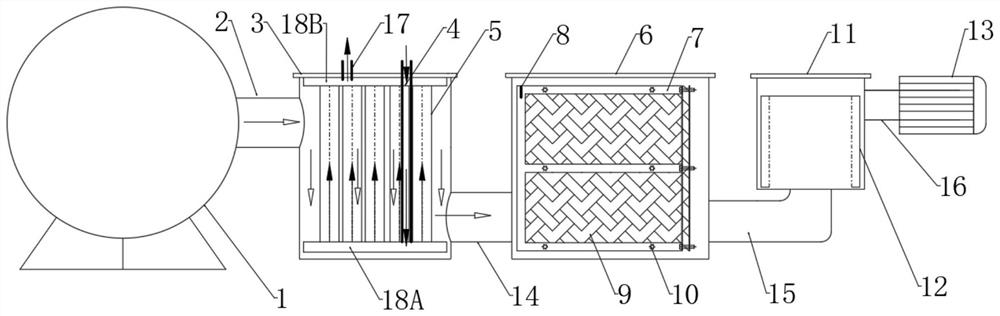

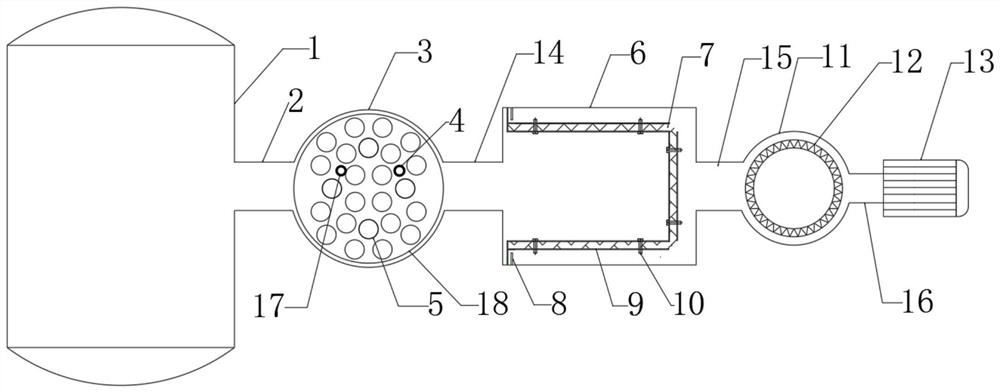

[0027] Such as figure 1 and 2 Shown, a kind of graphite thermal film carbonization furnace vacuum filtration system comprises carbonization furnace 1, filter assembly and vacuum pump 13, and the gas outlet of described carbonization furnace 1 is connected with the air inlet of filter assembly by the first exhaust pipe 2, so The air outlet of the filter assembly is connected to the vacuum pump through the fourth exhaust pipe 16; the filter assembly includes a primary condensation filter 3, a secondary adsorption filter 6 and a tertiary adsorption filter 11 arranged in sequence.

[0028] The air inlet of the primary condensing filter 3 is connected with the air outlet of the carbonization furnace 1 through the first exhaust pipe 2, and the air outlet of the primary condensing filter 3 is connected with the air inlet of the secondary adsorption filter 6 Connected by the second exhaust pipe 14, the air outlet of the secondary adsorption filter 6 is connected with the air inlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com