Intelligent control system applied to PVC drying fluidized bed

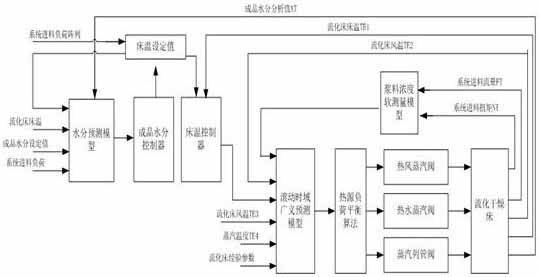

An intelligent control system and fluidized bed technology, applied in drying solid materials, drying cargo handling, heating to dry solid materials, etc., can solve the problem that the moisture content of the heating terminal cannot be measured, the feed volume of the drying system cannot be measured, and the process control response cannot be measured. Difficulty and other problems, to avoid superposition coupling phenomenon, improve dynamic controllability, and reduce the trouble that moisture cannot be measured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] 1. Material concentration soft sensor model:

[0067] First collect the material feed flow FT, torque / power value NI, and then analyze the current actual feed flow FT', NI' through the online signal preprocessing module to reduce noise, and finally obtain the reference value C through the analysis of the equipment operating conditions, and obtain the actual material The dimensionless parameter α of feed amount is as follows: , so the total weight of materials entering the fluidized bed at the current moment .

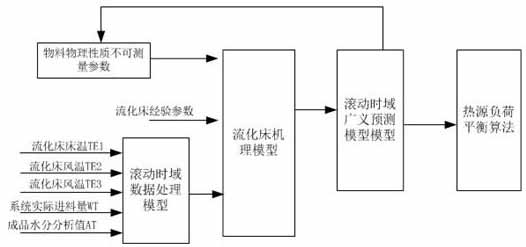

[0068] 2. Rolling time-domain generalized forecasting model algorithm:

[0069] First, it is necessary to analyze the actual drying residence time h of the fluidized bed and the reasonable discrete processing time φ of the data according to the fluidized bed process and the actual control process, and then the core data rolling processing array corresponding to the time length can be obtained through the rolling time domain:

[0070] {TE 1 (T0), TE 1 (T0+1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com