Ultralow-load sulfur recovery system and process

A sulfur recovery and loading technology, which is applied in the direction of sulfur compounds, sulfur preparation/purification, inorganic chemistry, etc., can solve the problems of burnout of the burner, tempering of the acid gas burner, etc., and achieve high flame turbulence and strong combustion , good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

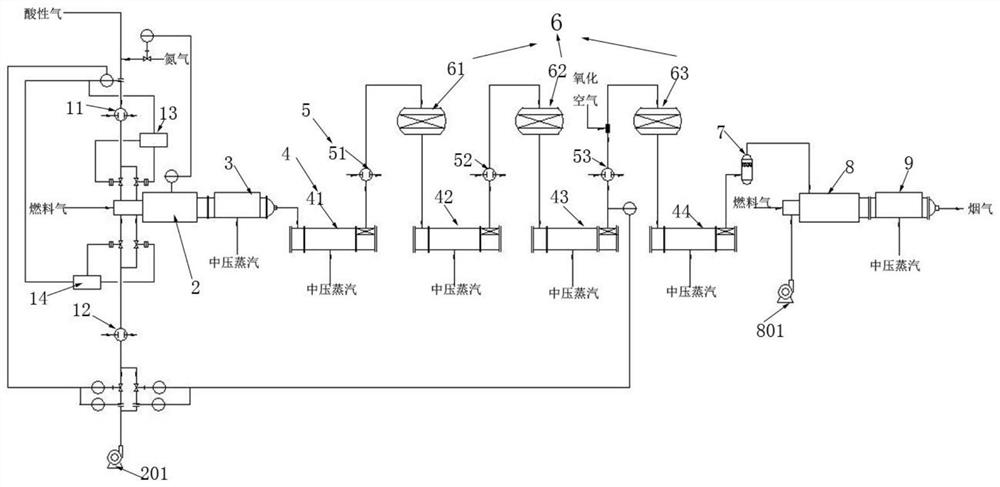

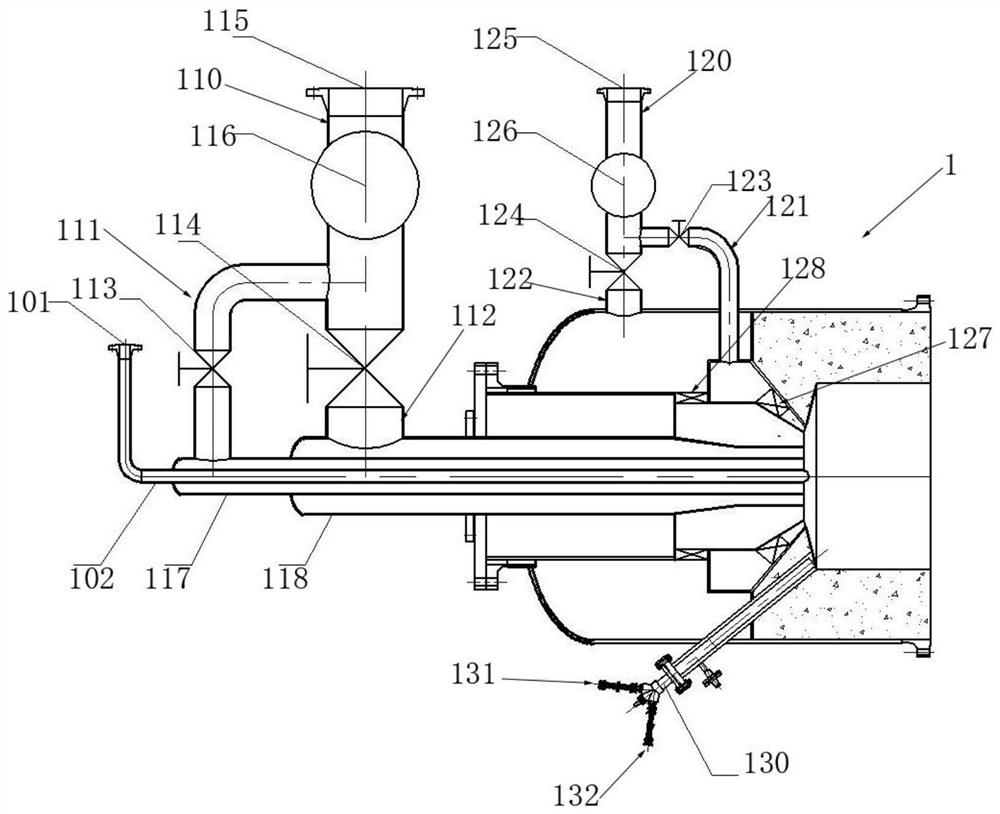

[0065] This embodiment proposes an ultra-low load sulfur recovery system, such as Figure 1-2 As shown, the ultra-low load sulfur recovery system includes a sequentially connected acid gas combustion unit and a tail gas treatment unit, the acid gas combustion unit includes a sequentially connected combustion furnace 2 and a combustion waste pot 3, and the tail gas treatment unit includes a condensing device assembly 4, reheater assembly 5, reactor assembly 6, catcher 7, incinerator 8 and incineration waste pot 9, first burner 1 is set on said burner 2, and said first burner 1 is provided with a two-stage acid gas passage 110 and a two-stage combustion air passage 120, and an acid gas spray gun assembly is arranged at the outlet end of the two-stage acid gas passage 110.

[0066] The ultra-low-load sulfur recovery system and process described in this embodiment can meet the needs of normal operation when the acid gas is 10%-30% of the design value, and the sulfur recovery rate ...

Embodiment 2

[0134] This embodiment proposes an ultra-low-load sulfur recovery process. The ultra-low-load sulfur recovery process uses an ultra-low-load sulfur recovery system as described in Example 1. The ultra-low-load sulfur recovery process includes the following steps:

[0135] S100: Acid gas and combustion-supporting air enter the combustion furnace 2 sequentially through the first burner 1 for combustion, and the high-temperature process gas generated by combustion is condensed in the combustion waste pot 3 to obtain liquid sulfur and recovered;

[0136] S200: The process gas condensed by burning the waste pot 3 enters the condensers, reheaters and reactors at all levels, and carries out the Claus reaction under the action of a suitable catalyst in the reactor to recover liquid sulfur. And the generated process gas is condensed through the condenser, and the deeply condensed process gas is carried out sulfur separation through the catcher 7;

[0137] S300: The tail gas after passi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com