Efficient preparation method of modified starch-lipid binary compound

A compound and starch technology, which is applied in the field of food processing, can solve problems such as poor emulsification ability and insolubility in cold water, and achieve the effect of improving interaction, emulsification ability, and good emulsification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

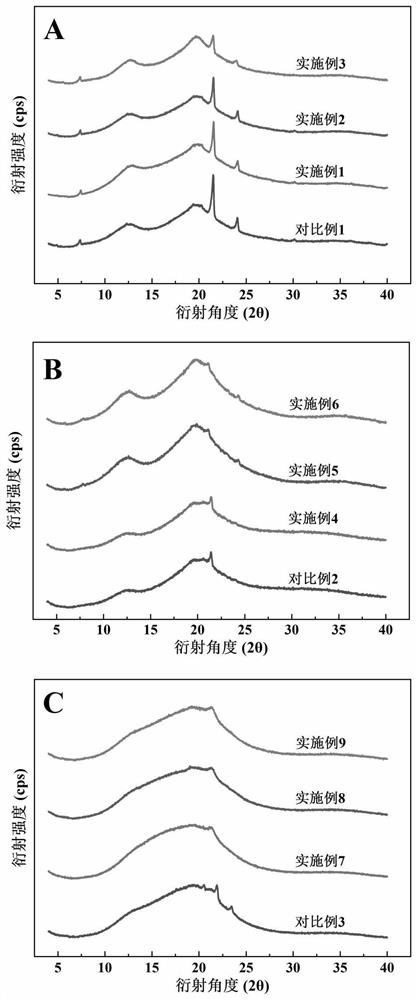

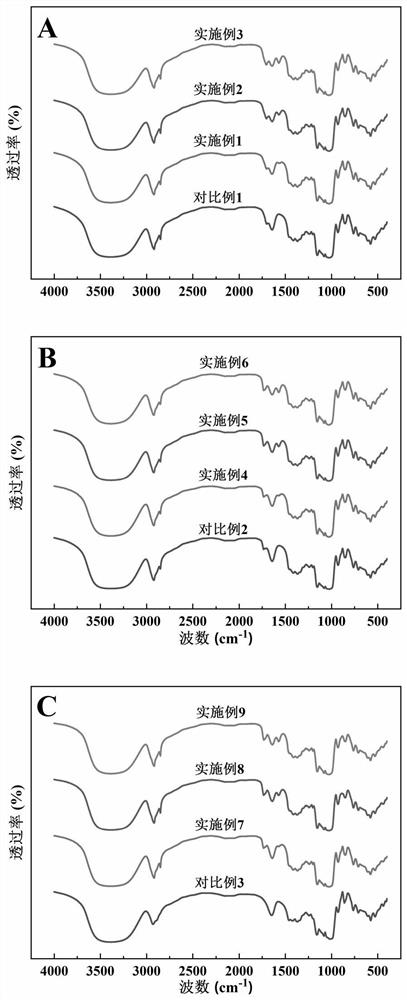

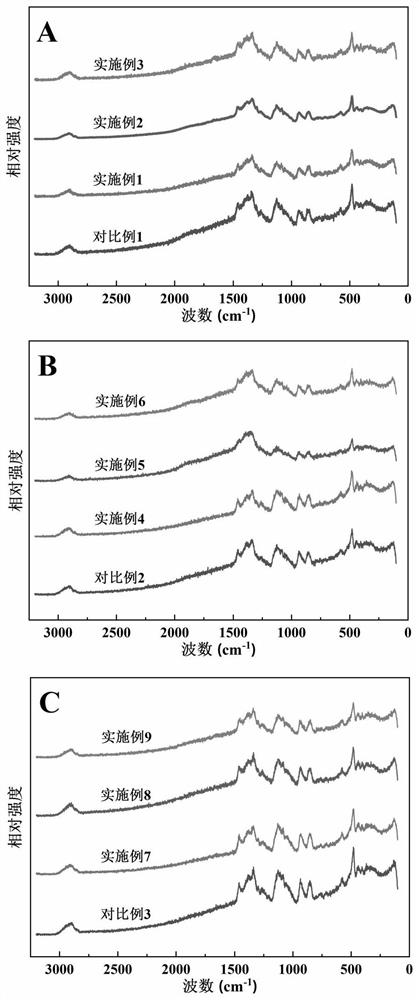

Embodiment 1

[0026] (1) Prepare conventional cornstarch with the prepared ionic liquid compound solution to form 10wt% starch milk; then add 0.5M sodium hydroxide solution to adjust the pH value of the system to 8.0-8.5; weigh the dry weight of starch 1 % octenyl succinic anhydride, at a temperature of 25°C, add dropwise to the system within 2.5h to modify the starch; the modification reaction lasts for 5h, and the stirring rate is 200rpm; after the reaction, adjust the pH value of the system to 6.0; Alternate centrifugation washing with deionized water and 70% ethanol, each 3 times, centrifugal force 5000g, centrifugation time 10min; dry in a vacuum oven at 40°C for 12h to obtain starch octenyl succinate.

[0027] (2) Premix starch octenyl succinate and deionized water for 3 minutes, and the stirring rate is 200 rpm to prepare 8 wt% starch suspension; then the mass ratio of lipid to modified starch dry basis is 1:20 Lipid was added, the stirring time was 2min, the speed was 260rpm, and th...

Embodiment 2

[0030] (1) Prepare conventional cornstarch with the prepared ionic liquid compound solution to form 10wt% starch milk; then add 0.5M sodium hydroxide solution to adjust the pH value of the system to 8.0-8.5; weigh the dry weight of starch 3 % octenyl succinic anhydride, at a temperature of 25°C, add dropwise to the system within 2.5h to modify the starch; the modification reaction lasts for 5h, and the stirring rate is 200rpm; after the reaction, adjust the pH value of the system to 6.0; Alternate centrifugation washing with deionized water and 70% ethanol, each 3 times, centrifugal force 5000g, centrifugation time 10min; dry in a vacuum oven at 40°C for 12h to obtain starch octenyl succinate.

[0031] (2) Preparation of modified starch suspension by premixing and the type and method of adding lipids are the same as in Example 1.

[0032] (3) The processing and preparation method is the same as in Example 1.

Embodiment 3

[0034] (1) Prepare conventional cornstarch with the prepared ionic liquid compound solution to form 10wt% starch milk; then add a 0.5M sodium hydroxide solution to adjust the pH value of the system to 8.0-8.5; weigh the dry weight of starch 9 % octenyl succinic anhydride, at a temperature of 25°C, add dropwise to the system within 2.5h to modify the starch; the modification reaction lasts for 5h, and the stirring rate is 200rpm; after the reaction, adjust the pH value of the system to 6.0; Alternate centrifugation washing with deionized water and 70% ethanol, each 3 times, centrifugal force 5000g, centrifugation time 10min; dry in a vacuum oven at 40°C for 12h to obtain starch octenyl succinate.

[0035] (2) Preparation of modified starch suspension by premixing and the type and method of adding lipids are the same as in Example 1.

[0036] (3) The processing and preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com