Primary combustion auxiliary heating electric arc furnace steelmaking equipment and method

An auxiliary heating and electric arc furnace technology, applied in the field of metallurgy, can solve the problems of large fluctuations in the flue gas temperature of the electric arc furnace, the inability to adapt to the flue gas of the electric arc furnace, and excessive emissions, so as to reduce the burning loss, reduce the burning loss of scrap steel, and increase the income. Effect of Furnace Temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] An electric arc furnace short-process steel plant has a 75-ton ultra-high-power electric arc furnace. In order to reduce costs and increase production capacity, it was originally equipped with a ladle oxygen burner to heat scrap steel. The thermal efficiency is less than 40%, the scrap steel burning loss is more than 11%, the flue gas only has dust removal, and the sulfur, nitrate and dioxin all exceed the standard. Because the environmental protection could not meet the standards, it was shut down by the local environmental protection department. Since there is no heating of scrap steel, the smelting cycle cannot meet the requirements of the continuous casting process, and frequent casting breaks occur, resulting in increased costs. In order to solve the problem of scrap steel preheating, the patented technology and equipment are adopted.

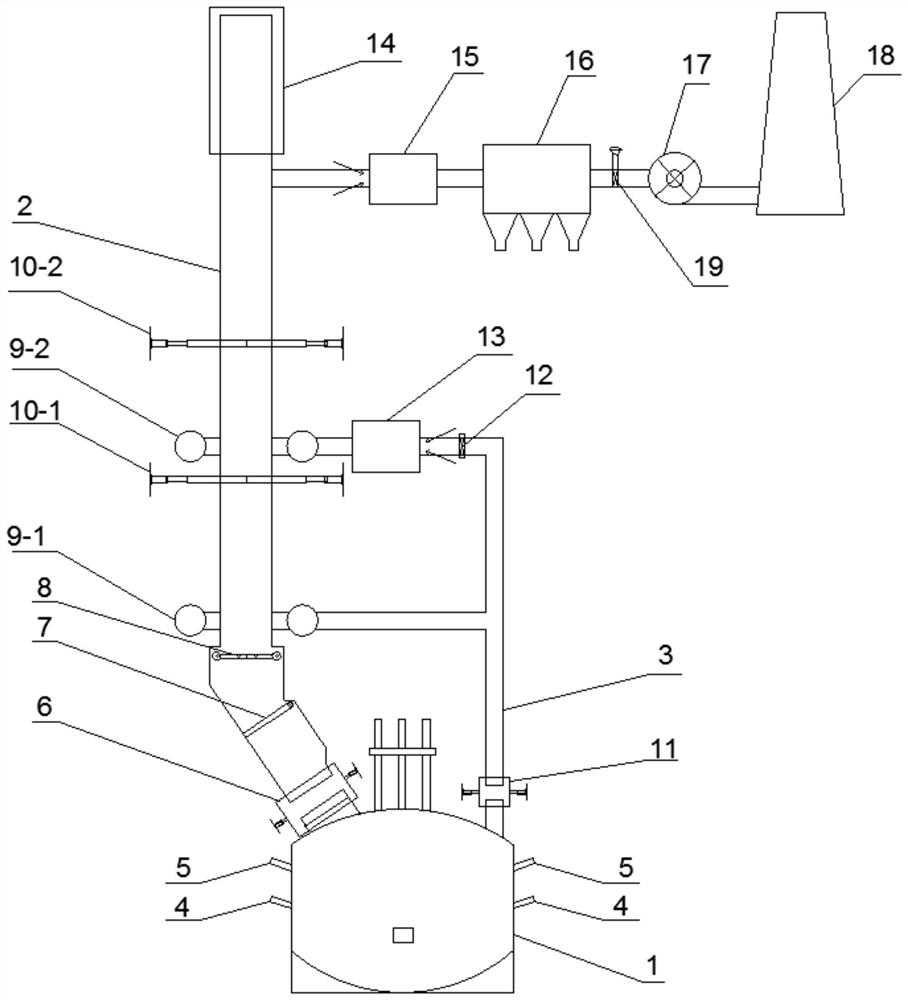

[0058] Primary combustion auxiliary heating electric arc furnace steelmaking equipment, its structure diagram is as follows figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com