Assembled TRC-steel pipe composite confined concrete column and installation method thereof

A constrained concrete and assembled technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of unimproved corrosion resistance, difficult hoisting and positioning, and complicated production, so as to improve the bearing capacity of axial pressure and avoid demoulding link, the effect of increasing the plastic yield capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

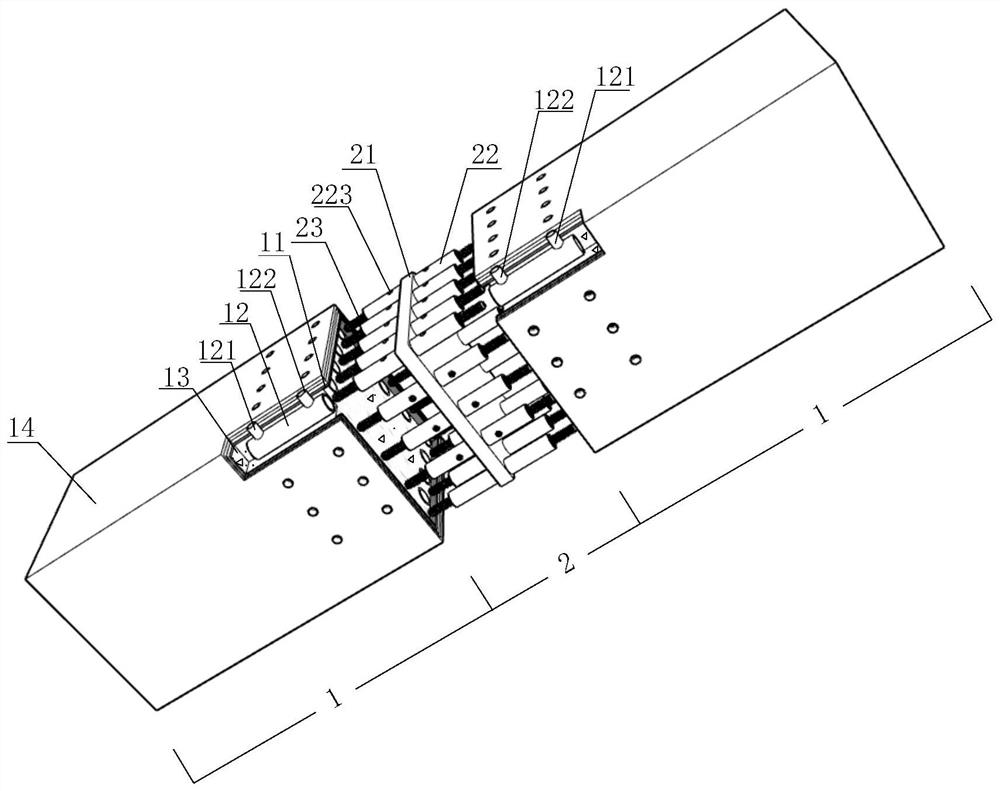

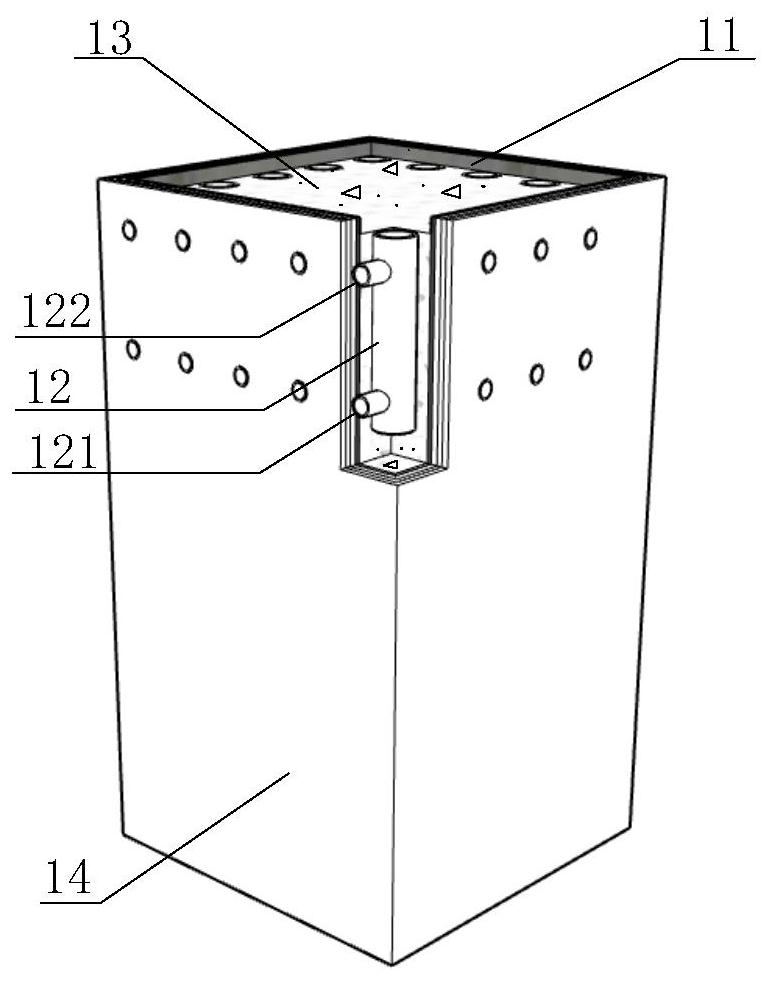

[0062] like figure 1 As shown, a prefabricated TRC-steel tube composite confined concrete column is composed of a TRC-steel composite confined concrete column segment 1 and a connecting steel plate assembly 2.

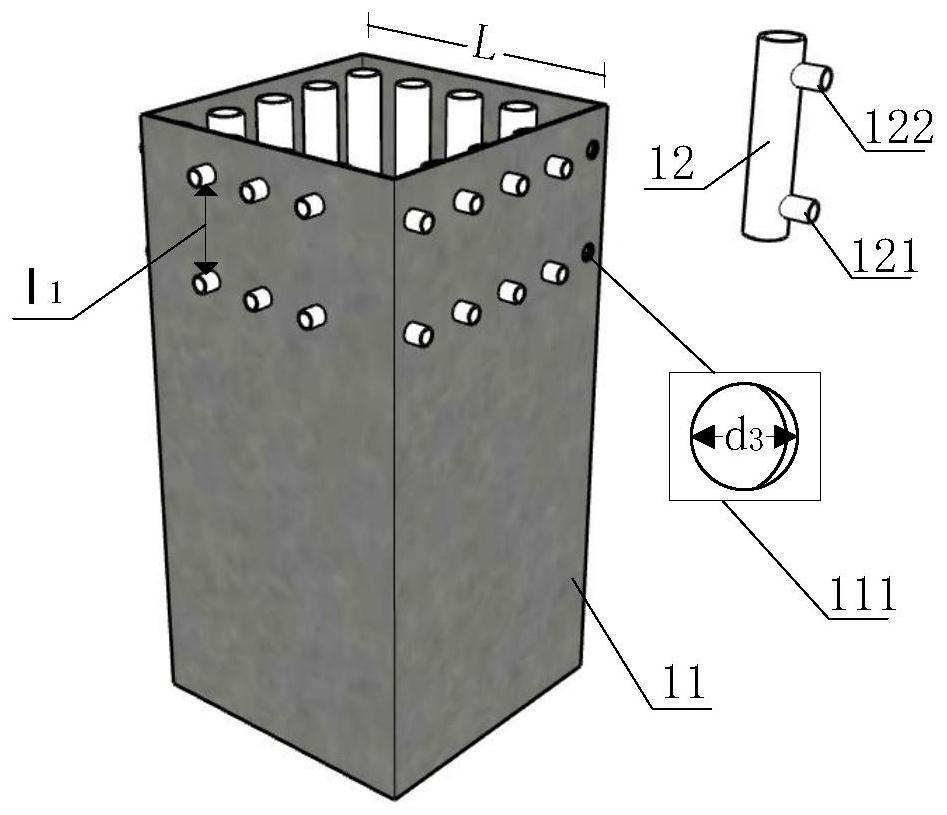

[0063] The prefabricated new steel plate assembly 2 is composed of a steel plate 21 , a small-diameter open sleeve 22 and a threaded steel bar 23 . Both sides of the steel plate 21 are provided with threaded holes 211 along the edge. The threaded holes 211 are through holes. After the diameter opening sleeve was fixed, its slurry outlet hole 223 was facing outwards. The threaded steel bars 23 run through the upper and lower small-diameter open sleeves 22 and the steel plate 21, and the threaded steel bars 23 are inserted and fixed in the threaded holes 211 into two coaxial small-diameter open sleeves 22, passing through the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com