Hazardous waste incineration system and operation process thereof

An incinerator and waste heat boiler technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of large increase in fly ash amount, corrosion of back-end equipment, increase in processing costs, etc., and achieve low system operating costs and dust content. The effect of reducing and reducing fly ash production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

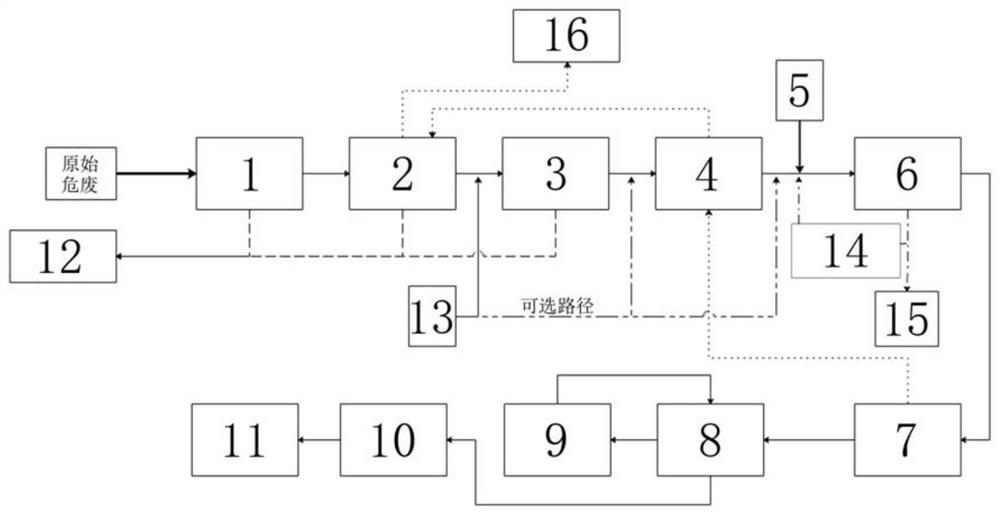

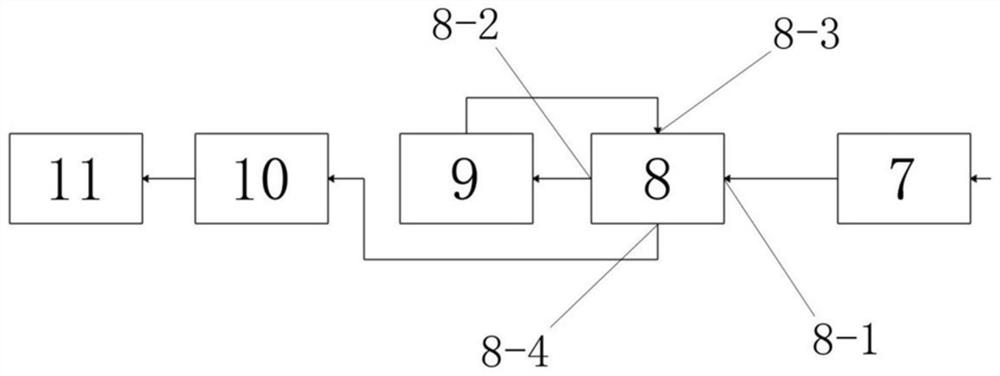

[0055] A hazardous waste incineration system, such as figure 1 As shown, including hazardous waste incinerator 1, primary waste heat boiler 2, high temperature dust collector 3, secondary waste heat boiler 4, dry deacidification system 5, medium and high temperature dust removal-denitration and dioxin removal device 6, economizer 7 , GGH flue gas heat exchanger 8, wet deacidification system 9, induced draft fan 10, chimney 11.

[0056] The hazardous waste incinerator 1 is sequentially connected to the first-stage waste heat boiler 2, the high-temperature dust collector 3, the second-stage waste heat boiler 4, the medium-high temperature dust removal-denitration and dioxin removal device 6, and the The economizer 7 and the GGH flue gas heat exchanger 8 are described.

[0057] The dry deacidification system 5 is arranged between the secondary waste heat boiler 4 and the medium-high temperature dust removal-denitration and dioxin removal device 6 through a flue.

[0058] Such a...

Embodiment 2

[0068] Adopt the hazardous waste incineration system described in embodiment 1 to carry out garbage incineration treatment, such as figure 1 As shown, the specific steps are as follows:

[0069] (1) After hazardous waste (garbage) enters the hazardous waste incineration system, it first enters the hazardous waste incinerator 1 for incineration. The hazardous waste incinerator 1 also includes a second combustion chamber, which provides an incineration temperature > 1100 ° C, and the flue gas residence time is 2s to reduce dioxin production.

[0070] (2) The high-temperature flue gas after incineration passes through the first-stage waste heat boiler 2 to recover the heat therein, and then cools down to about 550°C and enters the high-temperature dust collector 3 (high-temperature ceramic dust collector). The high-temperature ceramic dust collector uses ceramic filter elements, which have high dust removal efficiency , temperature resistance and corrosion resistance, dust remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com