Method for removing impurity mercury from crude selenium

A technology for the removal of crude selenium, applied in the field of removing impurity mercury, can solve the problems of complex invention process, high cost, and large consumption of reagents, and achieve the effect of simple process, convenient operation, safe and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

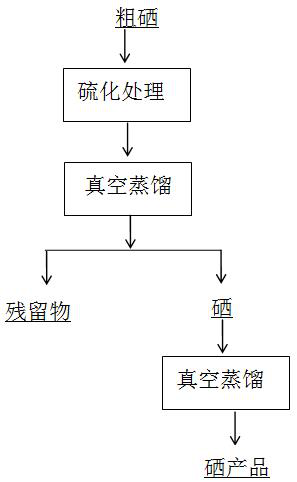

[0022] A method for removing impurity mercury from crude selenium, specifically comprising the following steps:

[0023] (1) Break 50g of selenium-containing waste (mercury content 3200ppm) into a powder below 200 mesh; mix the obtained powder with sulfur (according to the molar ratio of mercury and sulfur is 1:10~1:20), briquette, press 4Mpa; put the mixed material into a closed furnace, and vulcanize for 60min at a temperature of 150°C in an inert atmosphere at a heating rate of 5°C / min to obtain a vulcanized product.

[0024] (2) The obtained sulfide product is directly subjected to vacuum distillation, the condition is that the heating rate is 5°C / min, 240°C, 1Pa, and the reaction is 100min. According to the affinity between metal mercury, selenium and sulfur, and the generated mercury sulfide and selenium The saturated vapor pressure is not the same, and selenium and mercury are separated by sulfidation-vacuum distillation; finally, selenium enters the gas phase and is co...

Embodiment 2

[0027] A method for removing impurity mercury from crude selenium, specifically comprising the following steps:

[0028] (1) Break 50g of selenium-containing waste (mercury content 3200ppm) into a powder below 200 mesh; mix the obtained powder with iron sulfide (according to the molar ratio of mercury and iron sulfide is 1:15), briquette, and the pressure is 6Mpa ; Put the mixed material into a closed furnace, and vulcanize for 45 minutes at a temperature of 200° C. to obtain a vulcanized product in an inert atmosphere at a heating rate of 10° C. / min.

[0029] (2) Vacuum distill the obtained sulfide product directly under the condition that the heating rate is 10°C / min, 260°C, 10Pa, and react for 80min. The saturated vapor pressure of selenium is different from that of selenium. Selenium and mercury are separated by sulfidation-vacuum distillation; finally, selenium enters the gas phase and is collected in the form of volatiles, forming mercury sulfide and enriching valuable e...

Embodiment 3

[0032] A method for removing impurity mercury from crude selenium, specifically comprising the following steps:

[0033] (1) Break 50g of selenium-containing waste (mercury content 3200ppm) into a powder below 200 mesh; mix the obtained powder with sodium sulfide (according to the molar ratio of mercury and sodium sulfide is 1:10), briquette, and the pressure is 8Mpa ; put the mixed material into a closed furnace, and in an inert atmosphere, the heating rate is 15°C / min, and the temperature is 250°C for 30min to vulcanize to obtain a vulcanized product.

[0034](2) Vacuum distill the obtained sulfide product directly under the condition that the heating rate is 15°C / min, 280°C, 20Pa, and react for 20min. The saturated vapor pressure of selenium is different from that of selenium. Selenium and mercury are separated by sulfidation-vacuum distillation; finally, selenium enters the gas phase and is collected in the form of volatiles, forming mercury sulfide and enriching valuable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com