Corrosion-inhibition anion intercalation layered double-metal hydroxide and preparation method and application thereof

An anion intercalation, layered bimetal technology, applied in chemical instruments and methods, silicon compounds, phosphorus compounds, etc., can solve the problems of unsatisfactory LDH anti-corrosion performance, improve waterproof and anti-corrosion performance, improve anti-corrosion performance, The effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention provides the preparation method of anion intercalation LDH described in the above technical scheme, comprising the following steps:

[0044] Water-soluble divalent metal salt M 1 2+ Y 1 , Water-soluble trivalent metal salt M 2 3+ Y 2 Mix with water to obtain a mixed metal ion solution; M in the mixed metal ion solution 1 2+ and M 2 3+ The molar ratio is (1.8~4):1;

[0045] Mixing the mixed metal ion solution, the alkaline reagent and the corrosion-inhibiting anion, and performing a hydrothermal crystallization reaction to obtain anion-intercalated LDH;

[0046] The corrosion-inhibiting anions include PO 4 3- and SiO 3 2- .

[0047] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0048] The present invention will water-soluble divalent metal salt M 1 2+ Y 1 , Water-soluble trivalent metal salt M 2 3+ Y 2 Mix with water...

Embodiment 1

[0086] (1) Anion intercalation LDH

[0087] Zn(NO 3 ) 2 ·6H 2 O, Fe 2 (SO 4 ) 3 9H 2 O is mixed with deionized water to obtain a mixed metal ion solution, in which Zn 2+ The concentration is 0.34mol / L, Fe 3+ The concentration is 0.17mol / L;

[0088] The mixed metal ion solution and the NaOH solution with a concentration of 0.6mol / L are mixed in equal volumes, placed in a polytetrafluoroethylene-lined autoclave, and NaOH is added. 2 SiO 3 9H 2 O mixed, Na 2 SiO 3 9H 2 O and Zn 2+ +Fe 3+ The molar ratio of the total amount is 1:3; hydrothermal crystallization at 150°C for 10h, naturally cooled to room temperature and filtered, the obtained solid component was washed to neutrality, and dried at 80°C for 12h to obtain anion intercalation LDH([Zn 0.67 Fe 0.33 (OH) 2 ] (SiO 3 ) 0.125 ).

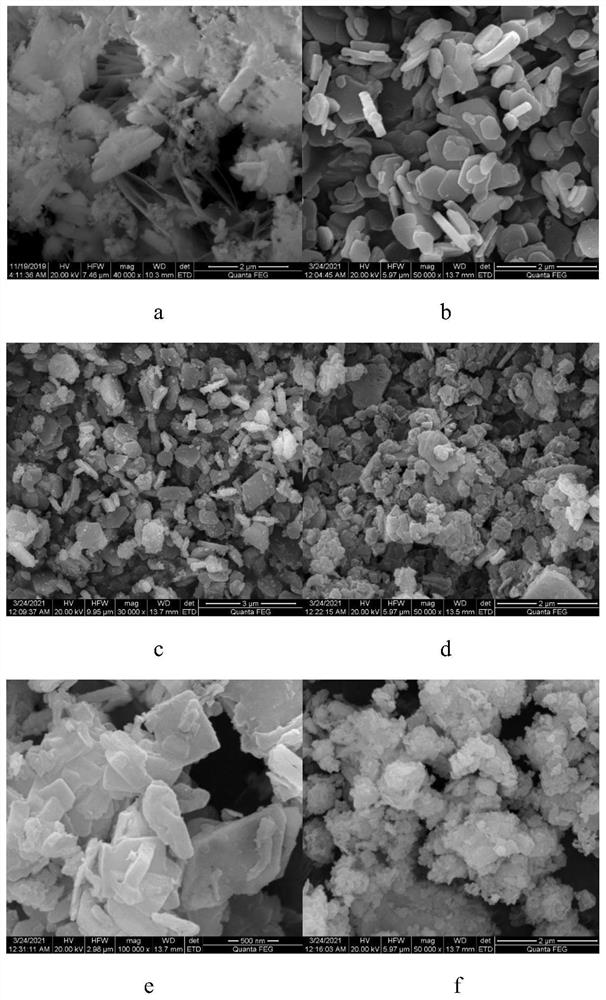

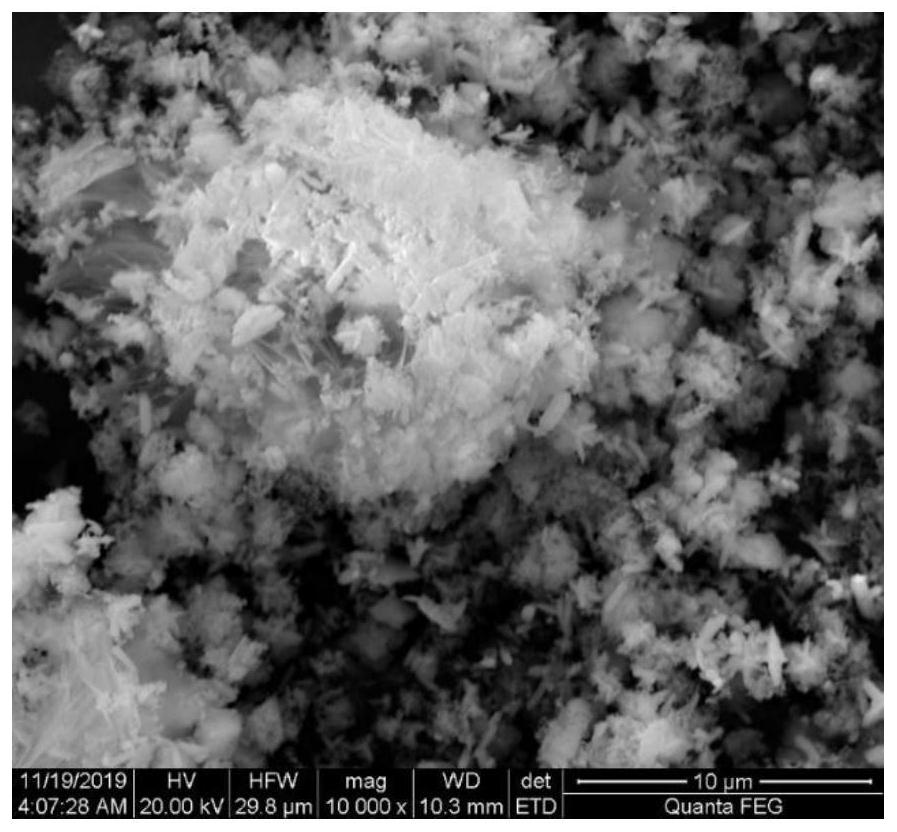

[0089] The scanning electron microscope picture of the anion-intercalated LDH prepared in this example is as follows figure 1 As shown in a, by figure 1 a It can be seen that...

Embodiment 2

[0094] (1) Anion intercalation LDH

[0095] Mg(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O is mixed with deionized water to obtain a mixed metal ion solution, in which Mg 2+ The concentration of Al is 0.34mol / L, Al 3+ The concentration is 0.17mol / L;

[0096] The mixed metal ion solution and the NaOH solution with a concentration of 0.6mol / L are mixed in equal volumes, placed in a polytetrafluoroethylene-lined autoclave, and NaOH is added. 3 PO 4 12H 2 O mixed, Na 3 PO 4 12H 2 O and Mg 2+ +Al 3+ The molar ratio of the total amount is 1:4; hydrothermal crystallization at 200°C for 8 hours, naturally cooled to room temperature and then filtered, the obtained solid component was washed to neutrality, and dried at 80°C for 12 hours to obtain anion intercalation LDH ([Mg 0.67 Al 0.33 (OH) 2 ](PO 4 ) 0.11 ).

[0097] The scanning electron microscope picture of the anion-intercalated LDH prepared in this example is as follows figure 1 b shown by figure 1 b It can be se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com