Production process of tempered glass lens

A tempered glass and production process technology, applied in chemical instruments and methods, cleaning methods using liquids, cleaning flexible objects, etc., can solve the problems of many defective products, long processing time, complicated production process, etc., and achieve convenient coating, Ease of operation and simplification of process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

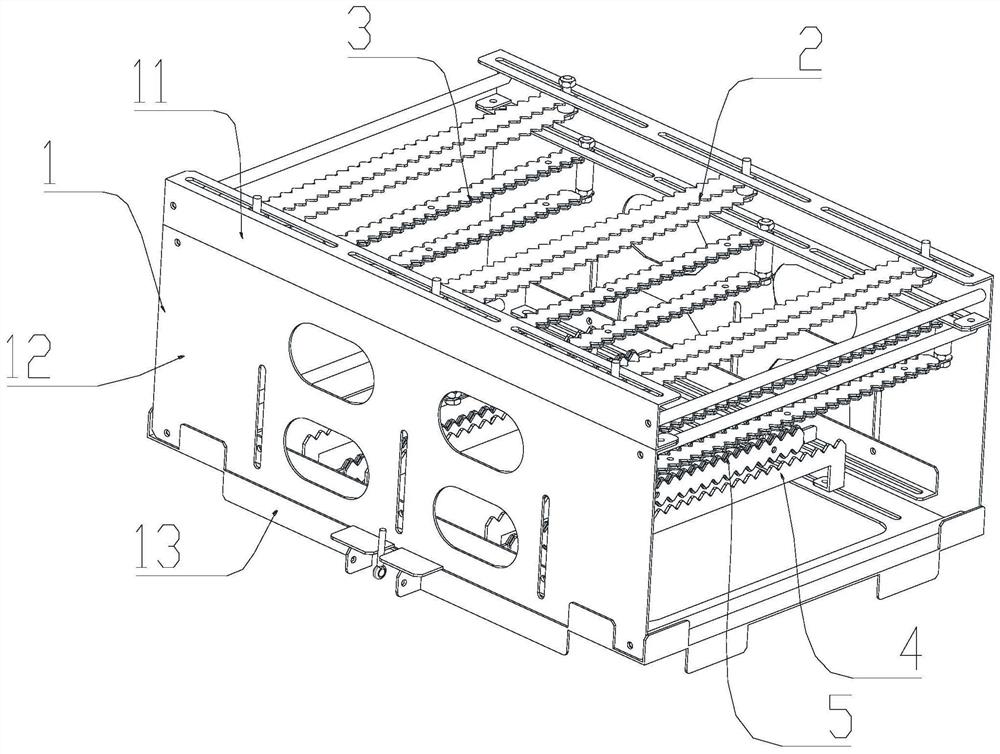

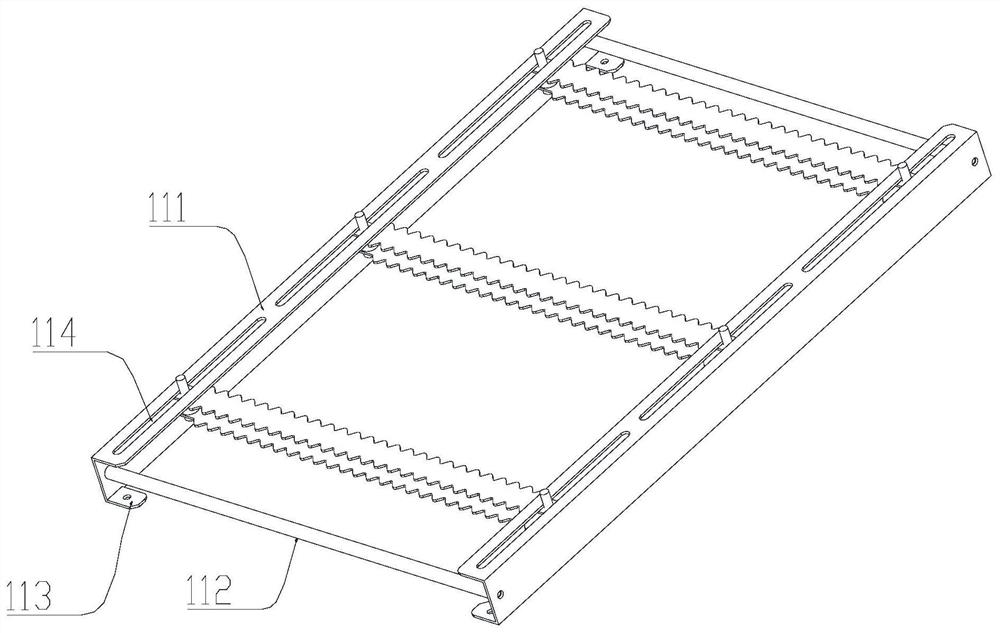

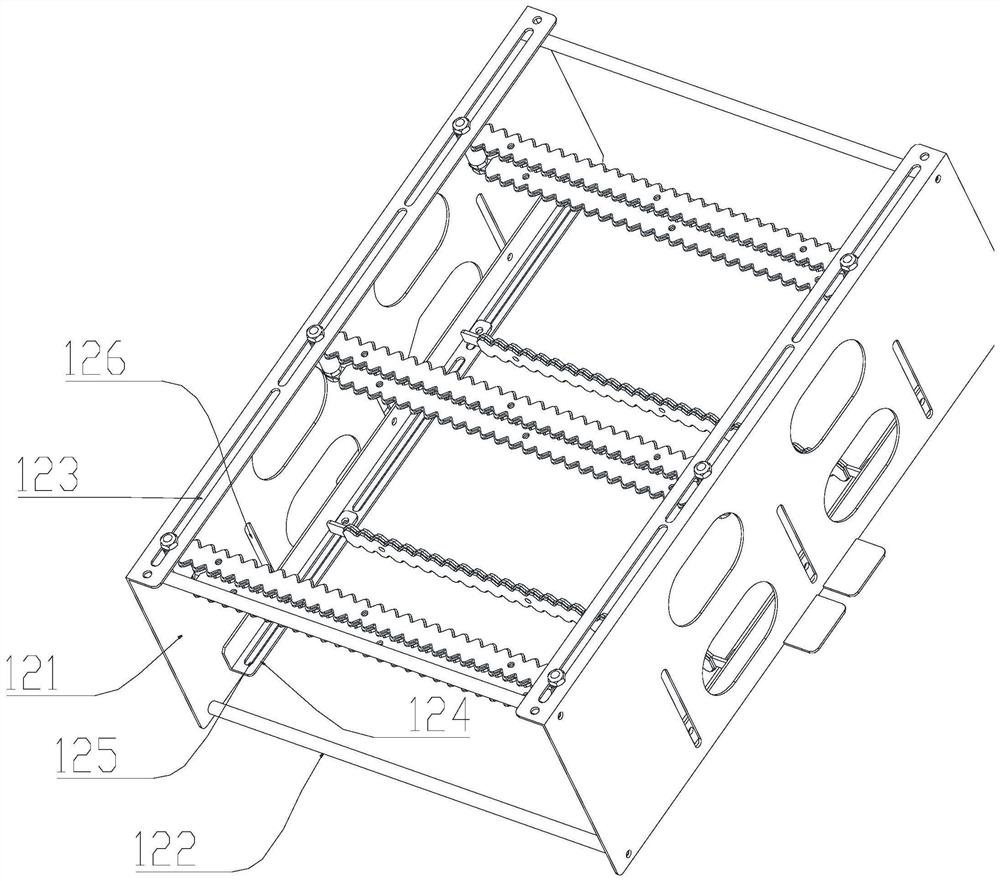

Image

Examples

Embodiment 1

[0050]A kind of production technology of toughened glass lens, it comprises the following steps:

[0051] Take the glass substrate for CNC molding, and then polish it. After polishing, use ultrasonic cleaning for 30 minutes at an ultrasonic frequency of 35 Hz. After ultrasonic cleaning, fix the glass substrate with a clamping device, and then perform chemical toughening treatment. The specific operation is to The glass substrate is preheated at 100°C for 0.5h, then strengthened with strengthening solution at 300°C for 2h, then cooled to 50°C, put into water containing cleaning agent, ultrasonically cleaned at 45°C for 5min, and then ultrasonically rinsed in pure water for 18min. Then dry, and coat the finished product after drying. The coating is to soak the tempered glass lens with titanium dioxide solution for 5 minutes, then take it out and dry it, and then use vacuum coating silicon dioxide solution. After coating, the tempered glass lens obtained Lenses are screen printed...

Embodiment 2

[0054] A kind of production technology of toughened glass lens, it comprises the following steps:

[0055] Take the glass substrate for CNC molding, and then polish it. After polishing, use ultrasonic cleaning for 90 minutes at an ultrasonic frequency of 45 Hz. After ultrasonic cleaning, fix the glass substrate with a clamping device, and then perform chemical toughening treatment. The specific operation is to The glass substrate is preheated at 300°C for 2 hours, then strengthened with strengthening liquid at 450°C for 10 hours, then cooled to 80°C, placed in water containing cleaning agent and ultrasonically cleaned at 75°C for 10 minutes, then ultrasonically rinsed in pure water for 25 minutes, and then Drying, and coating the finished product after drying, the coating is to first soak the tempered glass lens with titanium dioxide solution for 10 minutes, then take it out and dry it, and then use vacuum coating with a pickaxe solution.

[0056] In this embodiment, the polis...

Embodiment 3

[0058] A kind of production technology of toughened glass lens, it comprises the following steps:

[0059] Take the glass substrate for CNC molding, and then polish it. After polishing, use ultrasonic cleaning for 50 minutes at an ultrasonic frequency of 40 Hz. After ultrasonic cleaning, fix the glass substrate with a clamping device, and then perform chemical toughening treatment. The specific operation is to The glass substrate is preheated at 180°C for 1.5h, then strengthened with strengthening solution at 320°C for 8h, then cooled to 60°C, placed in water containing cleaning agent, ultrasonically cleaned at 55°C for 6min, and then ultrasonically rinsed in pure water for 15min. Then dry, and coat the finished product after drying. The tempered glass lens is first soaked in titanium dioxide solution for 7 minutes, then taken out to dry, and then vacuum coated with silicon dioxide solution and pickaxe solution.

[0060] In this embodiment, the polishing powder is made of ceri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com