Large-area-array high-sensitivity flexible elastic pressure sensor and preparation method thereof

A pressure sensor, flexible and elastic technology, which is applied in the field of large area array high-sensitivity flexible and elastic pressure sensor and its preparation, can solve the problems of insufficient array area, insufficient stretchability and flexibility, etc., and achieves large array area, high sensitivity, The effect of expanding the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

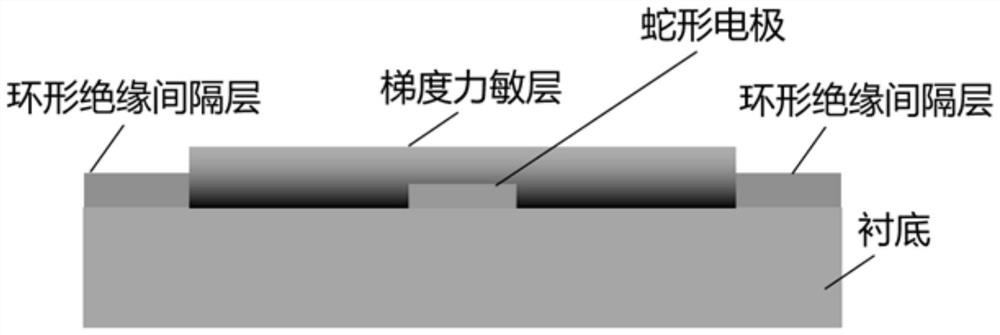

[0055] see figure 1 , is a composite layer structure diagram of a large area array high-sensitivity flexible elastic pressure sensor of the present invention. Specifically, the large area array high-sensitivity flexible elastic pressure sensor of this embodiment includes a first force-sensitive composite layer and a second force-sensitive composite layer.

[0056] In this embodiment, the structure of the first force-sensitive composite layer is the same as that of the second force-sensitive composite layer, and the composite layer includes a substrate, a transition layer, a spacer layer, an electrode layer and a force-sensitive layer, and the electrode layer is silver electrode.

[0057] Force-sensitive layers include conformal graphene films, micro-nano multilevel coatings, and high-resistance coatings. The conformal graphene film is formed by spraying graphene microsheet slurry on the substrate and electrode layer for the first time, and the micro-nano multi-level coating ...

Embodiment 2

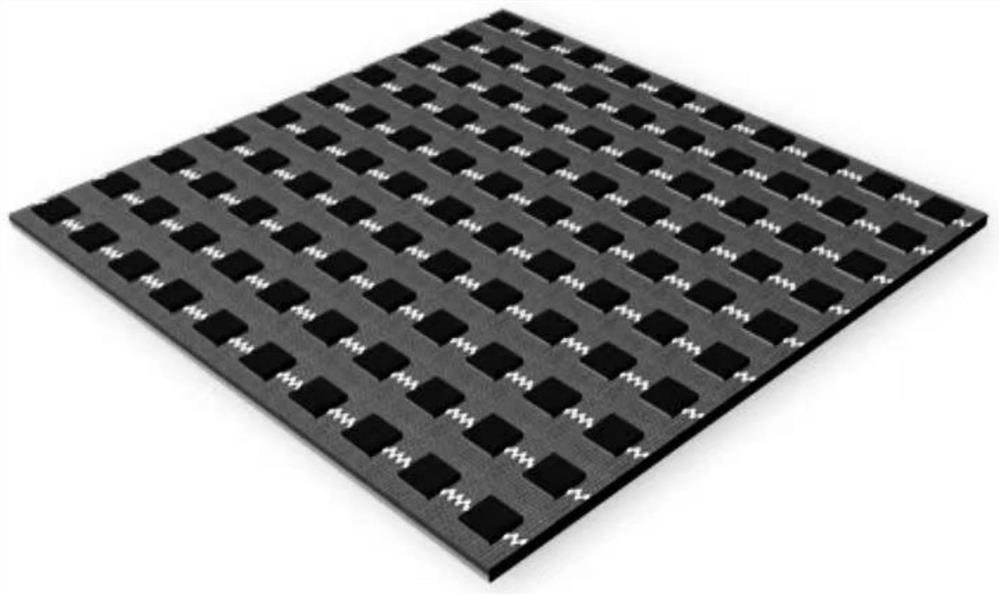

[0069] In order to more clearly illustrate the structure and preparation method of a large area array high-sensitivity flexible elastic pressure sensor of the present invention, the following combination figure 2 and image 3 Explain in detail. see image 3 , is a flow chart of the preparation process of a large area array high-sensitivity flexible elastic sensor of the present invention, specifically, it includes steps:

[0070] S11, processing two pieces of leather respectively. In this embodiment, nitrogen low-temperature plasma is used to treat two artificial leather fabrics, which can improve the film-forming uniformity of the water-based force-sensitive paste and the silver paste.

[0071] S12, preparing a transition layer and an electrode layer on two pieces of leather by screen printing technology. In this embodiment, the transition layer is a serpentine polyurethane, and the electrode layer is a serpentine silver paste electrode. The serpentine structure can make...

Embodiment 3

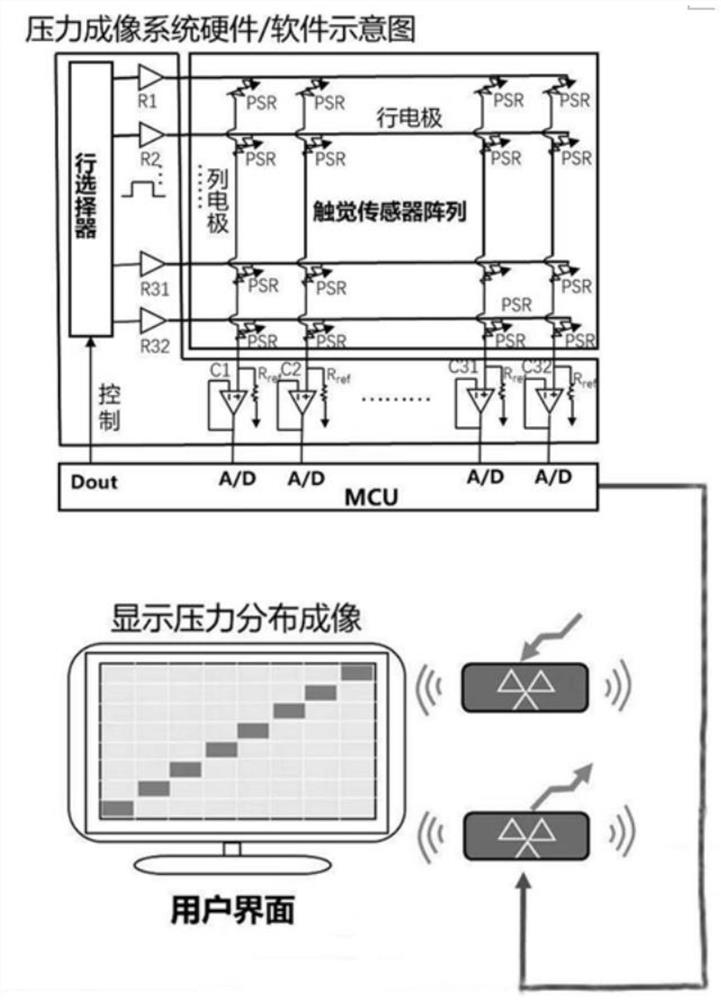

[0079] This embodiment is a pressure imaging system made by using the large area array flexible elastic pressure sensor obtained by the preparation method of the present invention together with other modules. In order to more clearly illustrate the working principle and composition of the system, the following combined Figure 4 , Figure 5 , Figure 6 Explain in detail.

[0080] Figure 4 It is the signal crosstalk analysis diagram of the array circuit. As shown in the figure, there is a signal crosstalk problem in adjacent unit devices. Figure 5 It is the principle diagram of the zero-potential scanning method of the array circuit. The voltage is applied to each row in turn through the row selector, and the voltage of the remaining rows is zero, so as to greatly reduce the row-column signal crosstalk and increase the speed of data reading.

[0081] Figure 6 It is the working principle diagram of the low-noise array acquisition circuit and the pressure imaging system of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com