A kind of hierarchical porous covalent organic polymer material and its preparation method and application

A polymer material, covalent organic technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problems of poor adsorption selectivity, slow adsorption rate of low-concentration mercury, etc., to enhance affinity and shorten synthesis Cycle, the effect of fast adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] A method for preparing a hierarchical porous covalent organic polymer material, comprising the following steps:

[0052] (1) Dissolve tetrakis-(4-aminobenzene)ethylene (ETTA) in water in a certain proportion, and add a certain amount of concentrated hydrochloric acid dropwise therein under ice-water bath conditions. The mixture was stirred for a certain time under an ice-water bath. Then, adding a certain concentration of NaNO 2 solution, the mixture was stirred for a certain period of time and then neutralized with NaOH solution to neutral and alkaline to obtain solution A;

[0053] The reaction process is:

[0054]

[0055] (2) Dissolving a certain amount of 1,4-phenyldithiol in a certain volume of NaOH solution, and ultrasonicating for a certain period of time to obtain solution B;

[0056] (3) Keep the ice-water bath condition, add solution B dropwise to solution A under stirring, and react the reaction system for a period of time under an inert gas environmen...

Embodiment 1

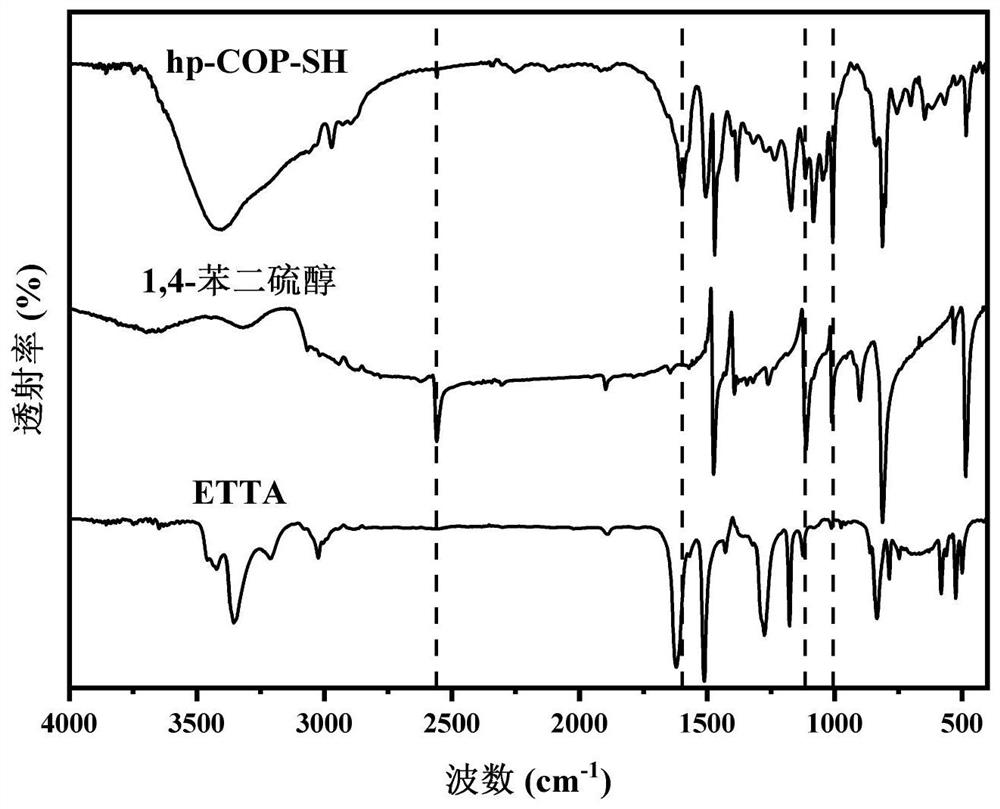

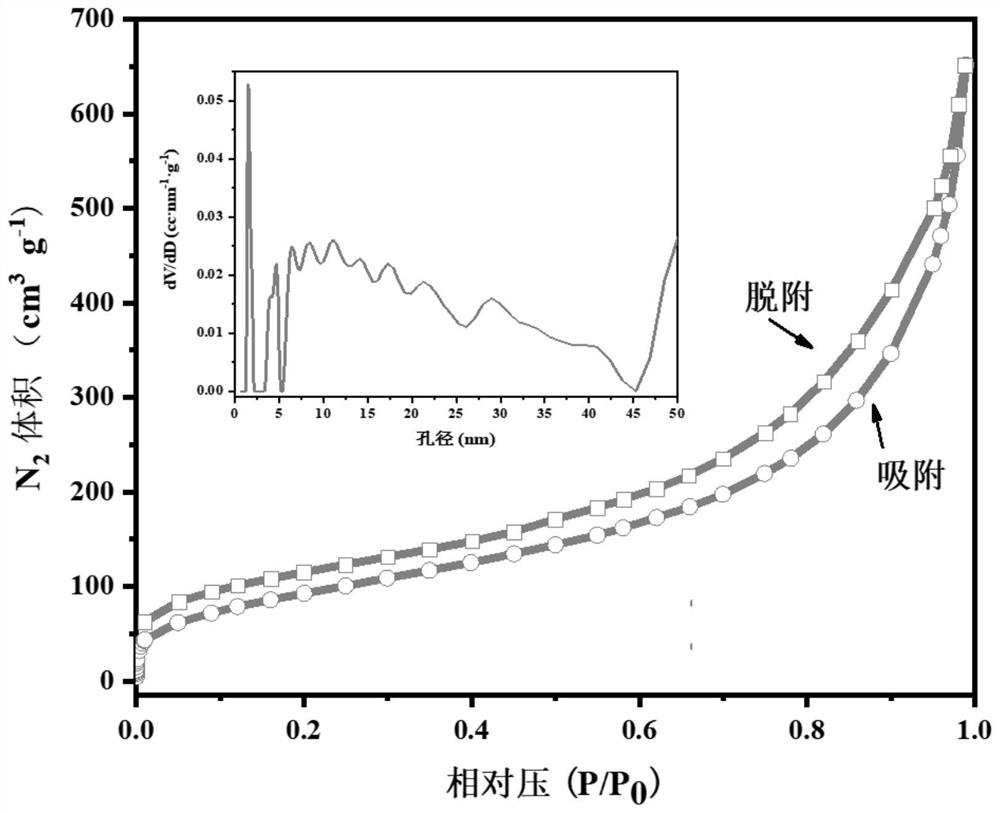

[0069] ETTA (0.25 mmol) was dissolved in water (25 mL), and 0.23 mL of concentrated hydrochloric acid was added dropwise thereto under ice-water bath conditions. The mixture was stirred for 15 minutes in an ice bath (0-5°C, 0°C was chosen). Then, keep adding 2.5mL NaNO at a rate of one drop every two seconds 2 (1.03 mmol) solution, the mixture was stirred for 30 minutes and then neutralized to pH=8.0 with 1M NaOH solution to obtain solution A. On the other hand, benzenedithiol (0.5 mmol) was dissolved in 10 mL of 0.1 M NaOH solution to obtain solution B. Solution B was sonicated for 20 min and then added dropwise to solution A with stirring at 0 °C. The reaction system was reacted under nitrogen atmosphere for 12 hours, washed with water and absolute ethanol for several times, and freeze-dried for 48 hours to obtain the target product hp-COP-SH.

[0070] like figure 1 As shown, it is a photo of hp-COP-SH, and the color of the sample is brownish red. The sample did not dis...

Embodiment 2

[0080] Carry out application test to hp-COP-SH material of the present invention:

[0081] (1) 10 mg of the hp-COP-SH sample prepared in Example 1 was added to a 30 mL Hg(II) concentration chamber of 30 ppb, Na + The concentration is 30ppm, K + Concentration is 80ppm, Ca 2+ , Mg 2+ 、Cu 2+ Concentration of 20ppm, Pb 2+ Concentration of 150ppb, pH = 6.5 ± 0.25 solution in the Erlenmeyer flask. Shake at a constant temperature in a water bath at 20°C for 10 minutes, take 5.00 mL and centrifuge, pass the supernatant through a 0.22 μm filter membrane, add 2% nitric acid to acidify and make the volume to 10.00 mL, and measure the concentration of various ions in the solution by ICP-MS. The result is multiplied by the dilution factor of 2 to obtain the actual concentration in the solution. In this way, the adsorption selectivity of hp-COP-SH to Hg(II) was evaluated.

[0082] like Figure 7 Shown are the separation factors and corresponding removal rates for different competing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com