High-degradation modified plastic particle

A technology of plastic granules and modification, applied in the field of preparation of degradable plastic granules, can solve problems such as environmental hazards and slow degradation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Prepare degradation agent, this degradation agent is made by following steps:

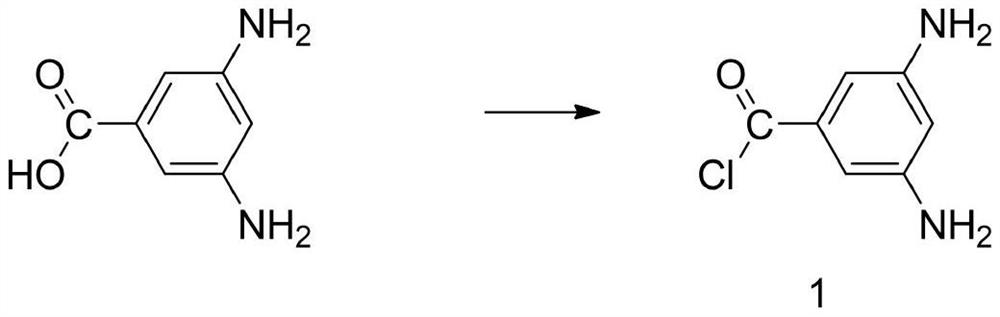

[0041]Step A1: Add 3,5-diaminobenzoic acid and deionized water into the flask, stir for 20min at a temperature of 45°C and a speed of 200r / min, then add thionyl chloride and N,N-dimethyl base formamide, the temperature was raised to 70°C, and the reaction was carried out under reflux for 5 hours. After the reaction was completed, the unreacted thionyl chloride was removed under reduced pressure, and the intermediate 1 was obtained after rotary evaporation;

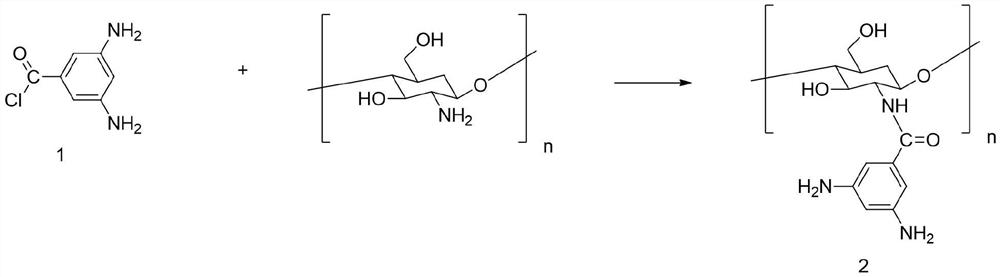

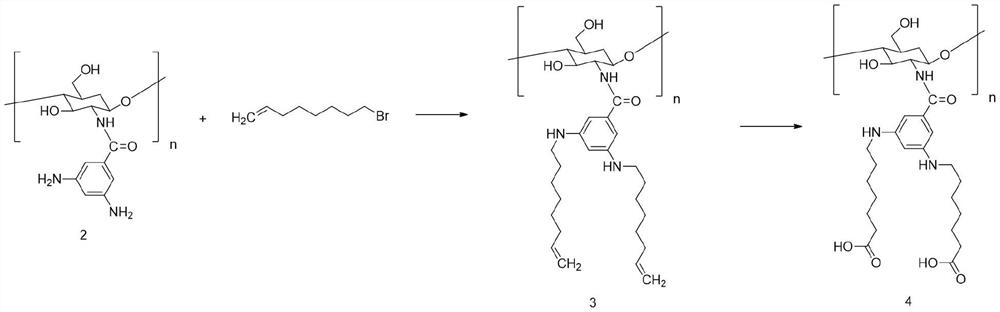

[0042] Step A2: Add chitosan into a flask equipped with deionized water, stir for 5 minutes at a temperature of 20°C and a speed of 300r / min, then mix intermediate 1 with toluene at a temperature of 5°C and a speed of 100r / min. The mixed solution was added dropwise into the flask, and then heated to 15°C for 8 hours of reaction. After the reaction, acetone was added and allowed to stand for 0.5 hours. After suction filtration, the filter...

Embodiment 2

[0047] Prepare degradation agent, this degradation agent is made by following steps:

[0048] Step A1: Add 3,5-diaminobenzoic acid and deionized water into the flask, stir for 20min at a temperature of 47.5°C and a speed of 300r / min, then add thionyl chloride and N,N-dimethyl base formamide, the temperature was raised to 70°C, and the reaction was carried out under reflux for 5 hours. After the reaction was completed, the unreacted thionyl chloride was removed under reduced pressure, and the intermediate 1 was obtained after rotary evaporation;

[0049] Step A2: Add chitosan into a flask filled with deionized water, stir for 7.5 minutes at a temperature of 25°C and a speed of 300r / min, then mix intermediate 1 with toluene at a temperature of 5°C and a speed of 100r / min The mixed solution was added dropwise into the flask, and then heated to 20°C to react for 12 hours. After the reaction, acetone was added and allowed to stand for 0.75 hours. After suction filtration, the filte...

Embodiment 3

[0054] Prepare degradation agent, this degradation agent is made by following steps:

[0055] Step A1: Add 3,5-diaminobenzoic acid and deionized water into the flask, stir for 20min at a temperature of 50°C and a speed of 400r / min, then add thionyl chloride and N,N-dimethyl base formamide, the temperature was raised to 70°C, and the reaction was carried out under reflux for 5 hours. After the reaction was completed, the unreacted thionyl chloride was removed under reduced pressure, and the intermediate 1 was obtained after rotary evaporation;

[0056] Step A2: Add chitosan into a flask equipped with deionized water, stir for 10 min at a temperature of 30°C and a speed of 300r / min, then mix intermediate 1 with toluene at a temperature of 5°C and a speed of 100r / min. The mixture was added dropwise into the flask, and then heated to 25°C to react for 16 hours. After the reaction, acetone was added and allowed to stand for 1 hour. After suction filtration, the filter cake was wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com